Introducing our 3003 Aluminum Composite Panel, a pinnacle of practicality and durability. Uniting style with strength, this panel is engineered for excellence. Crafted from high-grade 3003 aluminum alloy, it ensures longevity while maintaining a sleek aesthetic. Its lightweight design facilitates easy installation, making it an ideal choice for various applications. Resistant to corrosion and wear, this panel is a testament to quality and reliability. Elevate your projects with the 3003 Aluminum Composite Panel – where resilience meets refined design.

| Product Name | 3003 Aluminum composite panel |

| Brand Name | Alumideas |

| Model Number | A-56051 |

| Advantage | Exceptional Durability, Effortless Installation, Resilient Construction |

| Usage | Architectural Cladding, Industrial Panels, Ceiling Systems |

| Surface treatment | PVDF spraying/ Powder coating/anodized brushed |

| Color | Alumideas’ colors, RAL colors, customers’ colors |

| Coating Brand | World Well-known brands: DNT, AKZO/ Chinese local long-lasting brands |

| Material | Aluminum Alloy 3003, 5052 etc. |

| thickness | 4.0 mm – 8.0 mm. Chinese national standard thickness is 4.0 mm. |

| Standard size | 1220 *2440 mm for each 3003 composite panel |

| Maximum size | 1700*5800 mm in developed dimension |

| Application | Building Construction, Interior Design, Industrial Equipment |

| Production capacity | 12,000 Square Meters/month |

| Delivery time | 13-35 working days |

| After-sale Service | Online installation guidance |

| Place of Origin | Foshan City, Guangdong Province, China |

| Note | Size above 1220*2440 mm will be more expensive than below 1220*2440 mm. |

We are a factory located in Foshan with more than 14 years of experience. As a factory, we not only have reasonable prices and good quality but also have good service experience as some of the best trading companies.

We provide 1100H24 and 3003H24. If you need a special aluminum alloy plate, please let us know.

The thickness that can be made is 2.0mm-15.0 mm.

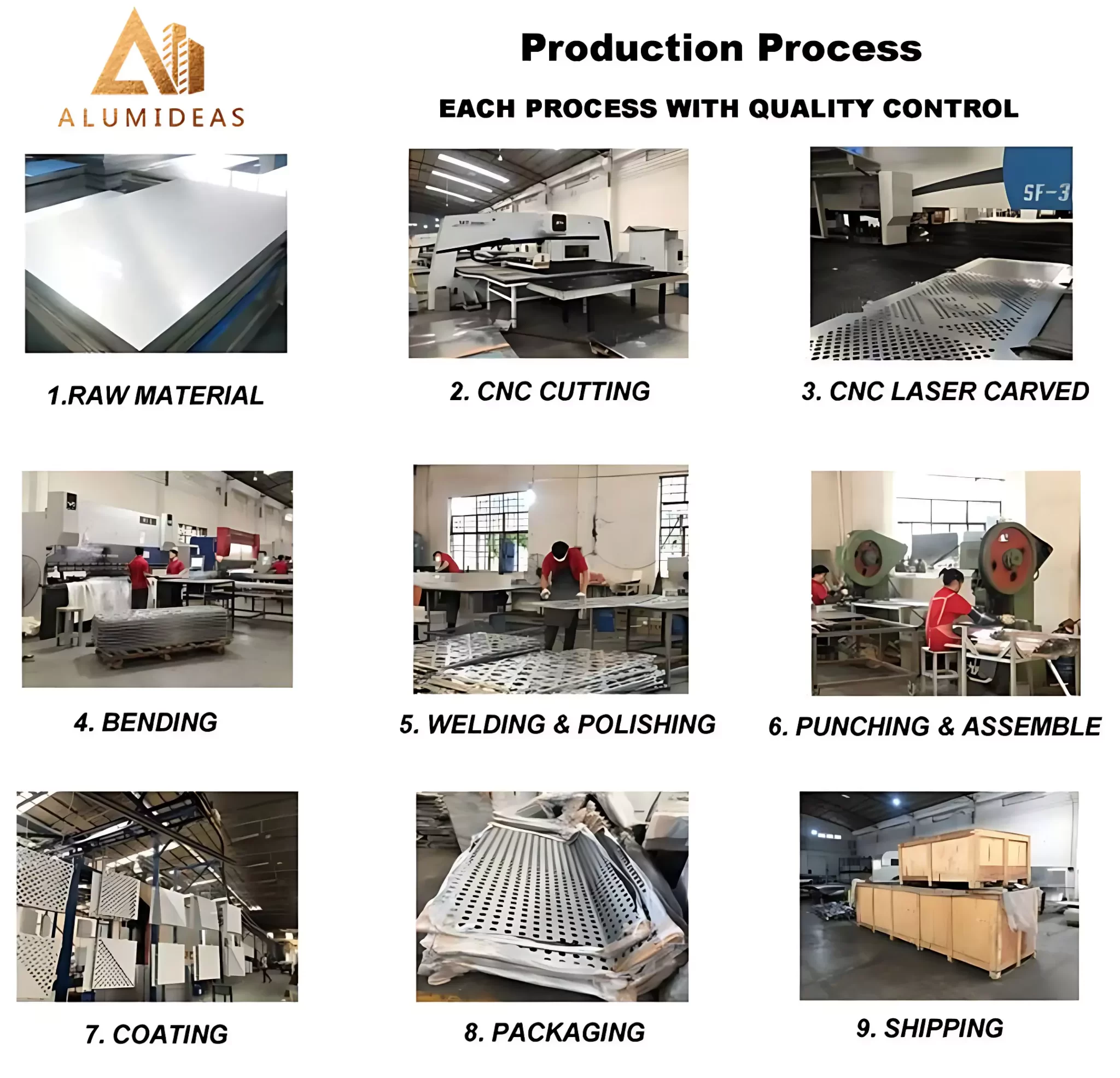

We have CNC machines for punching and engraving, laser machines for welding and engraving, folding machines, arc rolling machines, grinding machines, spraying production lines, and PVDF lines to meet any production and process requirements.

We have powder coating, paint spraying, PVDF spraying, wood grain, and stone grain.

Packaging:

Our aluminum plates come in various packaging options to suit your preferences and needs:

Choose the shipping method that best suits your needs:

– LCL (Less than Container Load): For bulk cargo, we use laminated wooden boxes that meet ISPM 15 standards. These boxes pass customs inspections without the need for fumigation.

– FCL (Full Container Load): When you purchase a full cabinet, we protect the aluminum plates by placing wooden strips at the bottom of the container. This prevents direct contact between the corner codes and the container, minimizing the risk of deformation during transportation.

– Rail transportation is available, especially for landlocked countries. China-Europe freight trains provide efficient transport with significant

Shipping Methods:

time savings compared to sea transportation, benefiting customers in some regions and improving project efficiency.

– Sea-rail combined transport offers a seamless way to transport goods through coastal seaports and railways. This method combines the advantages of cost-effectiveness and large cargo capacity of ocean and railway transport, saving costs and reducing environmental impact.

Choose the packaging and shipping options that best meet your requirements, ensuring the safe and efficient delivery of our aluminum plates to your destination.

Stephen

+86 13143187082

Alumideas is an aluminum wall cladding and interior ceiling system manufacturer in China. We provide a one-stop solution for your interior and exterior decorative cladding projects. Ask for a quote now!

We will contact you within 1 working day, please pay attention to the email with the suffix “@alumideas.com”.

Quick Info Exchange Helps Us Serve You Better

Get an instant quote from our professional consultants.

We will contact you within 1 working day, please pay attention to the email with the suffix “@alumideas.com”.