1. Introduction:

Welcome to our comprehensive guide on aluminum perforated panels. Aluminum perforated panel is a popular building material due to their versatility, durability, and aesthetic appeal. In this article, we will cover everything you need to know about aluminum perforated panels, including their definition, types, benefits, applications, and more. Our main question is: What is aluminum perforated panels and why is it important?

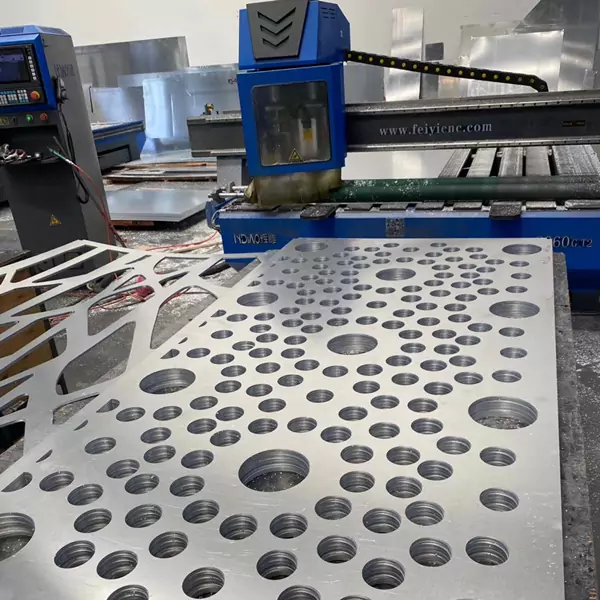

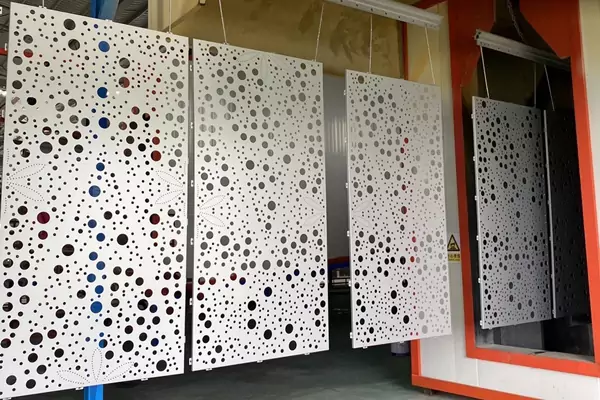

Aluminum perforated panels production

To make sure you can quickly find the information you need, we have prepared a content directory. When you click on it, you will be taken to the corresponding section.

Section of content

2. What is Aluminum Perforated Panel?

Aluminum perforated panel is a type of perforated metal panel that is made from high-quality aluminum sheets. The aluminum sheets are punched with a series of small holes to create a pattern, allowing air and light to pass through. This creates a decorative metal panel that is both functional and visually appealing.

3. Definition of aluminum perforated panel

Aluminum perforated panel is a type of metal panel that is punched with a series of small holes to create a pattern. The panel is made from high-quality aluminum sheets, making it lightweight, durable, and easy to install. The perforations can be customized to create a unique pattern or design, making it an ideal material for decorative metal panels.

4. Types of aluminum perforated panel

There are various types of aluminum perforated panels available in the market, each with its unique features and benefits. Some of the most common types of aluminum perforated panels include:

- Aluminum cladding panel: These panels are commonly used in building facades, as they provide a modern and contemporary look to the building. The perforations allow air and light to pass through, while also providing privacy and security.

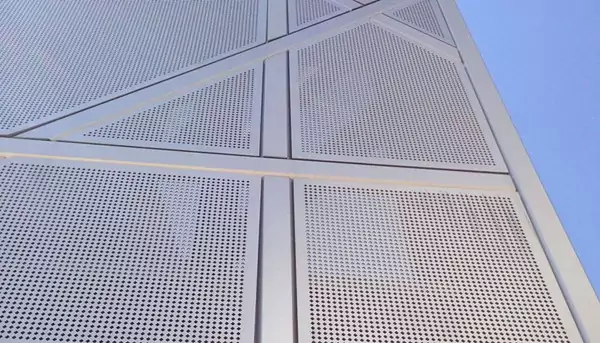

Aluminum cladding perforated panels

- Metal ceiling tiles: These panels are commonly used in commercial and industrial buildings, as they are easy to install and maintain. They provide excellent sound insulation and are available in various patterns and colors.

- Metal wall panel: These panels are commonly used in interior and exterior walls, as they provide excellent thermal insulation and soundproofing. They are available in various patterns and colors, making them ideal for decorative purposes.

Metal wall panel

- Facade panel: These panels are commonly used in building facades, as they provide a modern and contemporary look to the building. The perforations allow air and light to pass through, while also providing privacy and security.

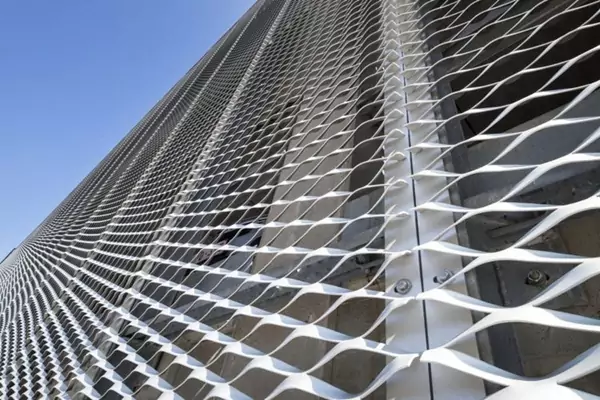

- Expanded metal mesh: These panels are commonly used in fencing and security applications, as they provide excellent visibility and ventilation. They are available in various patterns and sizes, making them ideal for different applications.

Expanded metal mesh

5. Benefits analysis

There are several benefits of using aluminum perforated panels, including:

- Lightweight: Aluminum perforated sheets are lightweight, making them easy to install and handle. They can be easily transported to the job site, reducing transportation costs and labor.

- Durable: Aluminum sheets are durable and long lasting, making them ideal for use in harsh weather conditions. They are resistant to corrosion, rust, and UV rays, making them ideal for outdoor applications.

- Customizable: Aluminum perforated sheets can be customized to create a unique pattern or design, making them an ideal material for decorative metal panels. They can be used to create a modern and contemporary look or a traditional and classic design.

- Energy-efficient: Aluminum sheets provide excellent thermal insulation and soundproofing, making them ideal for use in commercial and industrial buildings. They can help reduce energy costs by improving the building’s energy efficiency.

- Versatile: Aluminum perforated panels are available in various patterns, sizes, and colors, making them ideal for different applications. They can be used in building facades, interior and exterior walls, ceilings, fences, and security applications.

6. Applications

Aluminum perforated panels are a versatile material that can be used in various applications, such as:

1. Interior and exterior decoration

Aluminum perforated panels are widely used in interior and exterior decoration projects, such as walls, ceilings, partitions, and sunshades. They can be used to create a unique and modern design that is both functional and visually appealing. These panels can be used to create a range of shapes, patterns, and designs, which can be customized to meet the specific needs of the project.

2. Architectural design

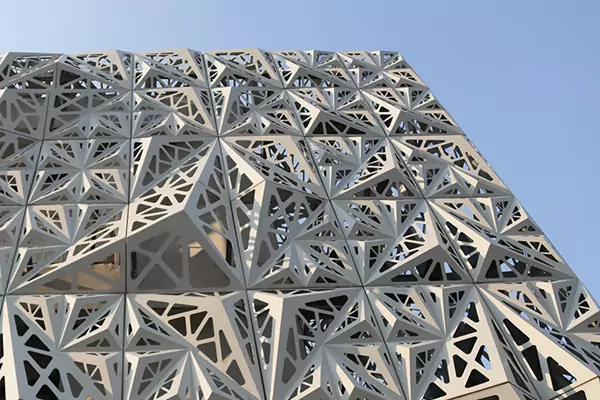

Aluminum perforated panels are a popular choice for architects and designers to create a unique and modern look for their projects. They are often used in commercial and residential buildings to add an aesthetic appeal to the structure. They can be used to create various shapes, patterns, and designs that can be customized to meet the specific needs of the project.

Three-dimensional structure cladding project3

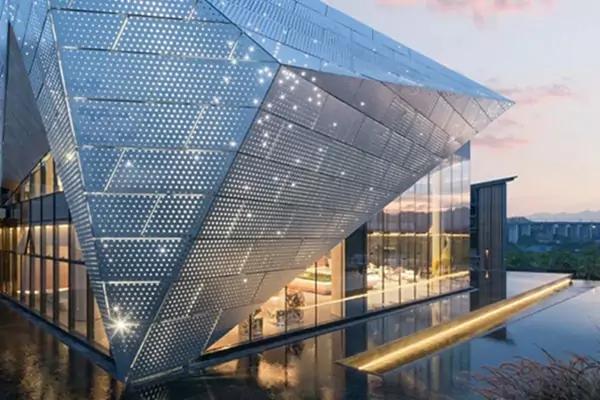

3. Cladding and facades

Aluminum perforated sheets are also commonly used as cladding and facades for buildings. They provide an effective way to protect the building from harsh weather conditions, while also adding an aesthetic appeal to the structure. The perforated design allows for natural ventilation, which is essential for buildings located in hot and humid climates.

Perforcated-Aluminium-Facade-Cladding

4. Acoustic insulation

Aluminum perforated panels are often used in projects that require acoustic insulation. The perforated design allows for sound waves to pass through the panel, which reduces noise levels in the surrounding environment. These panels can be used in various applications, such as concert halls, theaters, and recording studios.

5. Filtration and separation

Aluminum perforated panels can be used for filtration and separation applications. They can be used to filter liquids and gases and to separate different materials. The perforated design allows for efficient filtration and separation, which makes them an ideal choice for various industrial applications.

7. How to Choose Aluminum Perforated Panel

When choosing aluminum perforated panels, there are several factors to consider to ensure that the panels meet the specific needs of your project. Here are some factors to consider when choosing aluminum perforated panels:

- Material and finish options

Perforated panels are available in various materials, such as aluminum, stainless steel, and brass. Each material has its own unique properties and benefits. In addition, they come in various finishes, such as anodized, powder-coated, and painted, which can affect the overall appearance and durability of the panels.

- Hole patterns and sizes

Aluminum perforated panels come in various hole patterns and sizes, which can affect the overall design and functionality of the panels. The hole patterns can range from simple round holes to more complex patterns, such as square, slotted, and hexagonal holes. The size of the holes can also vary depending on the specific needs of the project.

- Thickness and size specifications

Aluminum perforated sheets come in various thicknesses and sizes, which can affect the strength and durability of the panels. The thickness of the panel can also affect its weight and cost of the panel. The size of the panel can vary depending on the specific needs of the project.

Aluminum sheet metal can be customized to meet the specific needs of the project. Customization options include hole patterns, sizes, finishes, and colors. This allows for greater flexibility in design and ensures that the panels meet the specific requirements of the project.

- Price and availability

Aluminum perforated panels vary in price depending on the material, finish, size, and customization options. It is important to consider the budget of the project when choosing. In addition, it is important to consider the availability of the panels, as some materials and finishes may have longer lead times than others.

Aluminum perforated panel production line

8. Common FAQ

As with any building material, there are some common questions that people have when considering the use of aluminum perforated panels. In this section, we will address some frequently asked questions about aluminum perforated panels.

Q: What is the thickness of the aluminum perforated sheet?

A: Aluminum perforated sheets come in a range of thicknesses, depending on the application. Typically, the thickness ranges from 1.5mm to 5mm. However, customized thicknesses are also available.

Q: What are the standard sizes of aluminum perforated panels?

A: The standard size of aluminum perforated panels varies depending on the manufacturer. However, most manufacturers offer a range of standard sizes, including 4×8 feet, 4×10 feet, and 5×10 feet. Customized sizes are also available based on the requirements of the project.

Q: How do you clean aluminum perforated panels?

A: Cleaning aluminum perforated panels is a simple process. You can use a mild detergent solution and a soft-bristled brush or a soft cloth to remove dirt and stains. Avoid using abrasive cleaners or wire brushes as they can scratch the surface of the panel.

Q: What is the price of the aluminum perforated panel?

A: The price of aluminum perforated panels varies depending on the thickness, size, and customization options. Typically, the cost ranges from $20 to $50 per square meter.

Q: How long do the aluminum perforated panels last?

A: Aluminum perforated panels are durable and long-lasting, with a lifespan of up to 20-30 years, depending on the maintenance and installation. They are resistant to corrosion, weather, and fire, making them suitable for both indoor and outdoor applications.

Q: Can aluminum perforated panels be recycled?

A: Yes, aluminum perforated panels are recyclable. Aluminum is a highly recyclable material, and it can be melted down and used to make new products.

Q: Can aluminum perforated panels be used for outdoor applications?

A: Yes, aluminum perforated panels can be used for outdoor applications. They are highly resistant to weather, corrosion, and fire, making them suitable for facades, cladding, and roofing applications. However, it is essential to choose a suitable coating and finish to ensure long-lasting performance.

9. Conclusion

In conclusion, aluminum perforated panels are an excellent choice for a wide range of applications due to their versatility, durability, and aesthetic appeal. They offer a range of benefits such as excellent ventilation, acoustic insulation, and energy efficiency, making them a popular choice among architects, engineers, and builders.

In this comprehensive guide, we have covered everything you need to know about aluminum perforated panels, from their definition, types, and benefits to their applications, selection criteria, and comparison with other materials. We hope this guide has been helpful in providing you with a better understanding of this material and its uses.

Remember, when choosing an aluminum perforated panel, it is important to consider the material and finish options, hole patterns and sizes, thickness and size specifications, customization options, as well as price and availability.

In summary, aluminum perforated panels are an ideal material for those looking to enhance the aesthetic appeal, energy efficiency, and sustainability of their building projects. With so many benefits and customization options available, aluminum perforated panels are a reliable and durable solution for any project.

Aluminum perforated panels cladding facade

Relate product:

Looking For a Facade Supplier For Your Projects?

Alumideas is a aluminum facade manufacturer in China. We provide a one-stop solution for your interior and exterior decorative cladding projects. Ask for a quote now!

We will contact you within 1 working day, please pay attention to the email with the suffix “@www.alumideas.com”.