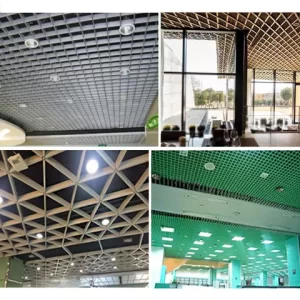

This article is a brief introduction of arc bending of aluminum profile for ceiling, aiming to distinguish arc bending from arc rolling, which are quite similar in word combination but totally different as they are used to describe different process in different industry. Om seker te maak dat jy die inligting wat jy soek vinnig kan vind, klik net op die inhoudsgids hieronder.

- 1.Basic Information About Aluminum Arc Bending

- 2.Parameters

- 3.Advantage of Arc Bending

- 4.Additional Information

- 5.Afsluiting

Basic Information About Aluminum Arc Bending

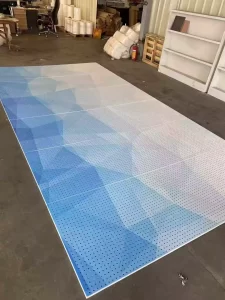

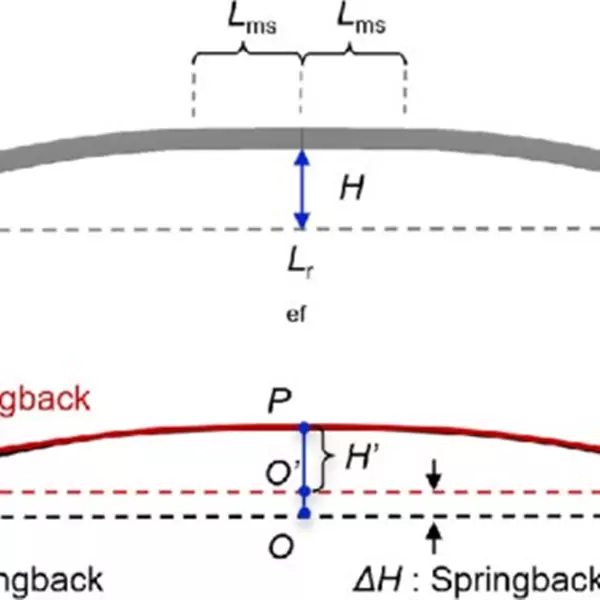

Aluminum profile arc bending is a process that bends metal sheets, pipes and profiles into work pieces with a certain curvature, shape and size. The biggest advantage of boog bending is the small amount of recovery. Stamping recovery refers to the physical change of the reduced or nearly reduced state when the metal sheet is deformed under the action of force and after the pressure is released.

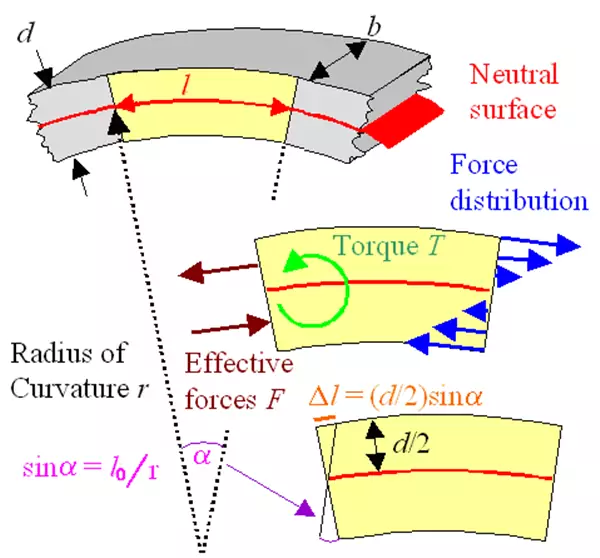

When the material is stretched and bent, the stress of each part in the deformation zone is different. The non-deformed part in the middle of the cross section is called the neutral layer. The metal other than the neutral layer is subjected to tensile stress, resulting in elongation deformation. The metal within the neutral layer is subjected to compressive stress, resulting in compressive deformation. Since the stress and strain directions of the metals on both sides of the neutral layer are opposite, when the load is removed, the elastic deformation recovery directions of the metals on both sides of the neutral layer are opposite, resulting in different degrees of recovery. Although the tension-bending deformation is limited to a certain area of the material, the rebound effect affects the accuracy of the whole profile. There are many factors that affect the recovery, and these factors are hard to control. The precision of the stretch-bending part affected by the recovery has always been the key to the production of stretch-bending profiles.

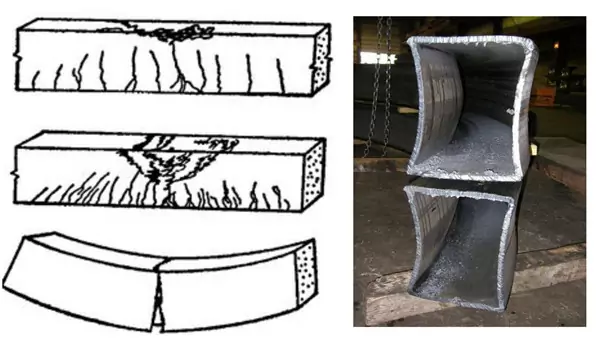

There are two main factors that limit the boog bending of aluminum profile in production: one is fracture, and the other is the excessive deformation of the section. These two aspects are the first things to be considered when determining the arc bending parameters. Fracture is the most destructive and common problem during the production of arc profiles. Stress concentration is the main reason for bending fracture. In order to avoid this situation, the surface quality of the profile should be checked before bending to ensure that there are no obvious scratches. Op dieselfde tyd, if the section size of the profile is changed by machining or other tools, it is necessary to ensure that the section size is the same at every place.

Daarby, minimizing the amount of elastic recovery is also one of the important basis for selecting the parameters of the stretch-bending process. In the processing of edge arc bending, improper selection of processing parameters will cause instability and wrinkling on the web, which is also an important factor to be considered. The extruded profile is considered as a special sheet metal material as the material itself has a dimension in one direction that is much smaller than the dimensions in the other two directions, so the forming process can usually be regarded as being completed in the plane stress state.

Parameters

Bending radius, section shape and stretching amount are three important parameters for arc bending of aluminum profile. Since the bending radius and section shape of the profile are often determined by the shape of the part, it is the key to the entire process to determine the appropriate amount of stretch. The smaller the bending radius of the profile for ceiling and the greater the stretching, the more obvious the degree of thickness reduction and upper surface collapse. When formulating the process, the value of the stretching amount must be greater than the minimum limit stretching amount.

Due to the presence of a steep drop zone in the recovery, when the requirements for thickness reduction are not very strict and no supplementary stretching measures are taken, the stretching amount can be chosen as close to the maximum limit stretching amount as possible to obtain higher accuracy.

Minimum bending radius:

(R outside – R inside) / R outside ≤ 8%

Maximum bending radius:

Unlimited as far as the mechanical properties of the material (elongation) allow.

Radius Tolerance:

If the radius is less than 1 meter, and the deviation of each meter length is less than ±1mm.

If the radius is greater than 1 meter, and the deviation of each meter length is less than ±2mm.

Maximum bending arc length:

The maximum length can reach 12 meters, which can improve installation efficiency, reduce installation costs, save materials and improve project quality for projects that require a longer arc length.

Maximum cold-formed section:

500mm*350mm

Material preparation length:

In general, the material preparation should be the sum of the effective arc length of the required bending material plus the process section. The process section is equal to 2.1 times the deformation width (t). The deformation width (t) is equal to the outer radius (R outer) minus the inner radius (R inner), so material preparation length equals to effective arc length plus 2.1t.

Advantage of Arc Bending

- After spraying, electrophoresis, electroplating, polishing, brushed, ens., the material can be bent directly without damaging the surface.

- Profiles with cavities and complex cross-sections can be formed at one time. When the relative bending radius allows, the inner surfacewill not be wrinkled and the section will not be distorted.

- Bending can effectively eliminate the residual stress inside the material, and the product has good dimensional stability.

- Due to the cold work hardening of the metal material, the comprehensive mechanical properties of the material can be improved after the material is stretched and bent.

Additional Information

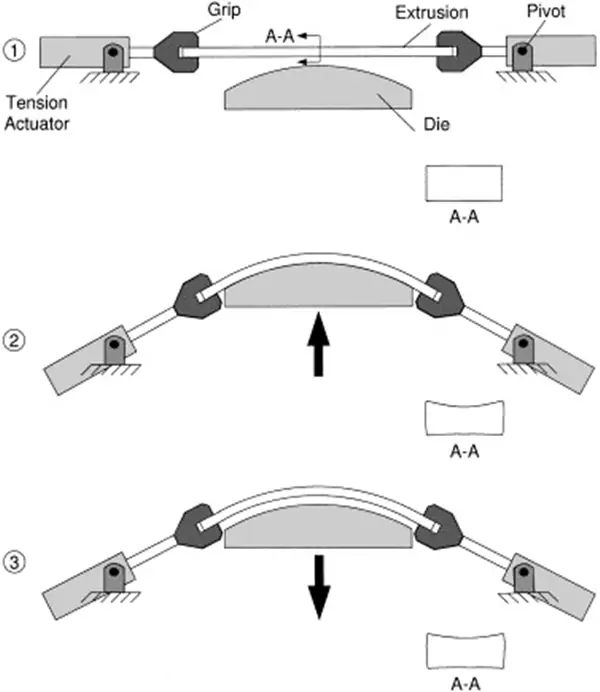

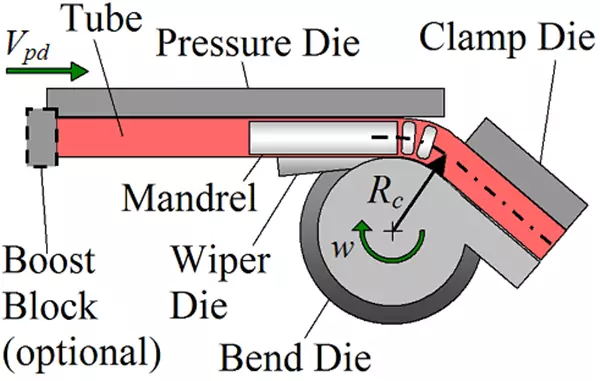

Oor die algemeen, according to the characteristics of its motion mechanism, stretch-bending forming equipment is divided into two types: tension arm benders and rotary benders.

Afsluiting

This article introduces some knowledge about arc bending of aluminum profile for ceiling, including basic information about arc bending, parameters, advantages and additional information about the types of aluminum benders.

In aluminum panel industry, arc bending is also applied as some customer may want aluminum tubes which are also included in the product list of aluminum panels supplied by Alumideas. Daarom, have a basic knowledge of arc bending might help those in need of aluminum tubes to choose their favored shape of aluminum tubes, offering them an additional option.

Opsoek na 'n fasadeverskaffer vir u projekte?

Alumideas is 'n vervaardiger van aluminiumfasade in China. Ons bied 'n eenstop-oplossing vir jou binne- en buite dekoratiewe bekledingsprojekte. Vra nou vir 'n kwotasie!

Ons sal jou binne-in kontak 1 werksdag, let asseblief op die e-pos met die agtervoegsel "@www.alumideas.com".