Einführung:

In diesem umfassenden Ratgeber, Wir werfen einen detaillierten Blick auf alles, was zu tun hat Aluminium-Verkleidungssysteme. Wir untersuchen den Herstellungsprozess, die verschiedenen Arten von Aluminiumverkleidungen, die Vorteile und Überlegungen, Installation und Wartung, Kostenfaktoren, führende Marken, und mehr.

Wenn Sie ein Architekt sind, der sich mit den unzähligen Verkleidungsmöglichkeiten befasst, oder möglicherweise ein Eigentümer, der darüber nachdenkt, dass Sie Ihrem Platz ein frisches Außengesicht geben, Dieses Handbuch entspricht. Es ist mit Nuggets der Weisheit gespickt, Stellen Sie sicher, dass Sie mit Klarheit und Zuversicht durch die komplizierte Welt der Aluminiumverkleidung navigieren.

Damit Sie die benötigten Informationen schnell finden, Wir haben ein Inhaltsverzeichnis vorbereitet. Wenn Sie darauf klicken, Sie werden zum entsprechenden Abschnitt weitergeleitet.

Inhaltsverzeichnis

Was ist Aluminiumverkleidung?

Aluminiumummantel, bestehend aus schlanken Blättern dieses Metalls, umhüllt die Fassade einer Struktur. Noch, Wenn wir über Gebäude und ihre Schutzschichten sprechen, Wir diskutieren im Wesentlichen darüber, wie diese dünnen Platten ein wesentlicher Bestandteil der äußeren Persona eines Gebäudes werden.

Die für die Verkleidung verwendeten Aluminiumblätter werden aus Aluminiumlegierungsplatten hergestellt. Die Legierungselemente wie Mangan, Magnesium, und Zink werden zu reinem Aluminium hinzugefügt, um ihm mehr Kraft und Haltbarkeit zu verleihen. Das legierte Aluminium wird in dünne Blätter gerollt, die geschnitten und in die gewünschten Verkleidungsformen gebeugt werden können.

Im Gegensatz zu tragenden Wänden, Aluminiumverkleidung ist kein strukturelles Element. Sein Zweck ist es, eine äußere Hülle zu schaffen, die das Gebäude vor dem Wetter schützt und auch die architektonische Ästhetik definiert. Es dient als zweite Haut, die sich um den strukturellen Kern eines Gebäudes wickelt.

Aluminiumverkleidung unterscheidet sich stark von anderen Formen der Verkleidung wie Ziegel, Holz, Stuck, und Vinyl. Zu den wichtigsten Unterschieden gehören:

- Die Aluminiumverkleidung ist viel leichter als die meisten anderen Verkleidungsoptionen. Dies erleichtert das Transport und die Installation.

- Es ist sehr langlebig und korrosionsresistent im Vergleich zur Holz- und Stuckverkleidung.

- Aluminium verbreitet weniger Feuer im Vergleich zur Vinylverkleidung.

- Es bietet eine bessere Isolierung als Ziegel- oder Betonverkleidungen.

Die Aluminiumverkleidung ist in einer breiteren Reihe von CGreater -Oberflächen im Vergleich zu Materialien wie Beton erhältlich.

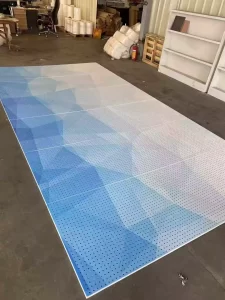

An der Außenwand der Turnhalle wird ein Aluminiumverkleidungssystem angebracht

Der Herstellungsprozess

Die Herstellung hochwertiger Aluminiumverkleidung erfordert fortschrittliche Fertigungstechniken und -prozesse. Hier sind die wichtigsten Schritte:

- Aluminiumspulenproduktion – Verkleidungsblätter beginnen als große Aluminiumspulen. Legierungen mögen 5000 Und 6000 Serien werden üblicherweise für die Architektur verwendet. Die Spulen werden auf die gewünschte Dicke gerollt, Typischerweise zwischen 0,7 mm und 1,6 mm.

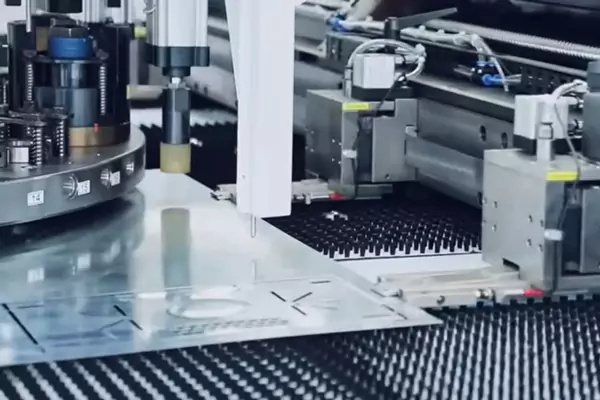

- Schneiden und Biegen – Computer numerische Steuerung (CNC) Maschinen schneiden die Spulenblätter in die gewünschten Plattenformen und -größen ab. Biegung und Herstellung erzeugen Paneele mit Falten, Schrägen, Wellen, oder Perforationen.

- Oberflächenbehandlung – Veredelungsprozesse wie Pulverbeschichtung oder Anodisierung werden verwendet, um Farbe anzuwenden, Textur und schützen Sie das Aluminium vor Verwitterung und Verschleiß. Bei der Pulverbeschichtung werden farbiges Polymerpulver auf das Metall aufgetragen und es in einem Ofen geheilt. Die Anodisierung erzeugt eine haltbare Oxidschicht auf der Oberfläche elektrolytisch.

- Laminierung (ACP)- Verbundplatten werden durch Laminieren von Aluminium zu Isolierpolymer oder Mineralkernen hergestellt. Dies verbessert die Starrheit und die thermische Leistung.

- Qualitätstests – In strengen Tests wird sichergestellt, dass die Aluminiumverkleidung Spezifikationen für die mechanische Leistung erfüllt, Beschichtungsanhaftung, Korrosionsbeständigkeit, und Brandbewertung.

Fortgeschrittene Geräte zum Präzisionsschneiden, Biegung und Herstellung sowie Fachkenntnisse in Bezug. Die Herstellungsprozesse formen das Metall zu langlebig, Kreativ geformte Panels.

Alumideas-Herstellungsprozess - Turmschlägen

Arten von Aluminiumverkleidungen

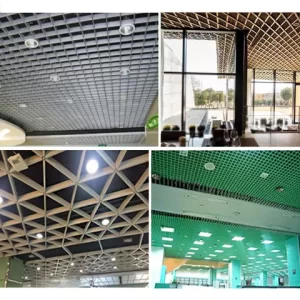

Die Aluminiumverkleidung bietet Vielseitigkeit, um unterschiedliche funktionale und ästhetische Bedürfnisse zu decken. Einige der Haupttypen umfassen:

- Aluminiumverkleidungsplatten – Diese bestehen aus festen Aluminiumblättern, die in gleichmäßige rechteckige oder quadratische Felder geschnitten sind. Das flache Plattendesign erzeugt ein elegant, Nahlose Fassade. Die Panelgrößen variieren, aber die gemeinsamen Abmessungen betragen 30 "x 10" oder 40 "x 10".

- Aluminiumverkleidung in Wohngebieten – Für Häuser oder niedrige Gebäude, Es werden häufig leichte Aluminiumprofile verwendet. Dazu gehören Wellblätter, Bretter, Gürtelrose, und vertikale Tafeln. Strukturierte Oberflächen bieten visuelles Interesse.

- Aluminiumwandverkleidung – Dies wird ausgiebig für Außenwände von Handelsgebäuden und Hochhäusern verwendet. Panels sind in verschiedenen Formen erhältlich, Perforationsmuster, und Anhaftungssysteme. Horizontale oder vertikale Orientierung ist möglich.

- Aluminium -Regenschutzmodelle – Regenbildsysteme haben einen beatmeten Hohlraum zwischen der Außenverkleidung und der Innenwand. Diese Doppelschichtkonstruktion bietet Wetterschutz und ermöglicht gleichzeitig Belüftung und Entwässerung. Beliebt für Hochhäuser.

- Wellblech -Aluminiumverkleidung – Zu kreischend gebildet, Wellblätter, Dies fügt Dimension und visuelle Anziehungskraft hinzu. Die Grate machen die Blätter starrer und verbessern die Entwässerung. Wellbleche Aluminium eignet sich auch gut für die Innenverkleidung.

- Vertikale Aluminiumverkleidung – Dies bezieht sich auf schlanke lineare Paneele, die vertikal ausgerichtet sind. Die schmalen aufrechten Paneele erzeugen eine Moderne, modernster Look. Rückenbeleuchtungseffekte können für zusätzliches Drama verwendet werden.

Vorteile der Aluminiumverkleidung

Aluminiumwandpaneele können auf verschiedene Weise beendet werden, um unterschiedliche ästhetische Effekte zu erzielen. Egal, ob Sie nach einem glatten suchen, mattes Finish oder strukturiert, glänzend, Alumideas kann die perfekte Lösung bieten. Wir bieten eine Reihe von Oberflächen an, einschließlich Pulverbeschichtung, Eloxieren, und PVDF -Beschichtung, Jedes bietet einzigartige Vorteile.

Architekten und Bauherren wählen Aluminiumverkleidungen für seine vielen Vorteile:

- Haltbarkeit– Aluminiums Antikorrosionseigenschaften verleihen ihm eine außergewöhnlich lange Lebensdauer von 40-50 Jahre. Es behält sein Erscheinungsbild mit minimaler Wartung bei.

- Geringer Wartungsaufwand– Die Aluminiumverkleidung erfordert nur gelegentliche Reinigung. Es braucht im Laufe seines Lebens keine Neulackierung oder besondere Instandhaltung.

- Wärmedämmung– Aluminium selbst führt Wärme durch, aber wenn sie mit isolierten Kernen verwendet werden, Es bietet sehr gute Isolationswerte. Dies verbessert die Energieeffizienz in Gebäuden.

- Akustische Dämpfung– Die isolierte Aluminiumverkleidung hilft dabei, Ein wichtiges Merkmal in städtischen Gebieten. Die Metallhaut dämpft externe Geräusche.

- Ästhetische Vielseitigkeit– Mit Optionen wie perforiert, geprägt, gewellt, gebürstet, oder metallische Oberflächen, Aluminium ermöglicht kreative Fassadendesigns mit anderen Verkleidungsmaterialien nicht möglich.

Vor- und Nachteile von Aluminiumverkleidung

Vorteile von Aluminiumverkleidungen:

- Extreme Haltbarkeit und Wetterbeständigkeit

- Erfordert nur sehr wenig Wartung über das lange Lebensdauer

- Leicht im Vergleich zu Materialien wie Naturstein oder Beton

- Ausgezeichnete Wärme- und Schalldämmung bei Verwendung mit Kernen

- Breite ästhetische Optionen zur Erfüllung von Designvisionen zur Verfügung

- 100% recycelbar am Ende des Lebens

Potenzielle Nachteile zu berücksichtigen:

- Höhere Anfangskosten als Faserzement oder Vinylverkleidung

- Die Installation kann kompliziert sein, Benötigt Aluminium -Expertise

- Das Erscheinungsbild nach der Installation schwer zu verändern

- Risiko einer galvanischen Korrosion in Kombination mit weniger edlen Metallen

- Die Leistung hängt stark von der Installationsqualität ab

Installationsprozess

- Verkleidungstafeln werden zu einem Unterrahmen montiert, nicht direkt an der Gebäudewand befestigt.

- Der Unterrahmen bietet die Stützstruktur und ist mit Klammern an der Wand befestigt.

- Verriegelung mit Befestigungsklammern verschränken sich, Schienen, oder Haken vorinstalliert auf dem Subframe.

- Dichtungen und Dichtungsmittel werden an wetterfesten Plattenverbindungen verwendet.

Wichtige Installationsüberlegungen

- Der Unterrahmen muss ausgelegt sein, um Windlasten und seismische Faktoren aufzunehmen.

- Die Zulage muss für die thermische Ausdehnung und Kontraktion von Panels erfolgt werden.

- Details an den Fugen und Verbindungen von Panel sind für wasserdicht.

- Erfahrene Installateure sollten für komplexe Formen und Ausrichtungen verwendet werden.

- Spezielle Geräte wie mechanische Lifte, die häufig für die Verkleidung mit Hochhäusern benötigt werden.

Wartung und Pflege

Die ordnungsgemäße Wartung ist der Schlüssel, um sicherzustellen. Eine regelmäßige Reinigung wird empfohlen, um das Aufbau von Schmutz- oder Umgebungsvorkommen zu verhindern. Verwenden Sie ein weiches Tuch, Schwamm oder Bürste mit warmem Wasser und einem milden pH-neutralen Reinigungsmittel. Vermeiden Sie abrasive Durchsuchungspulver oder Pads, die das Finish kratzen könnten. Für hartnäckige Flecken, Spezialisierte Aluminiumreiniger können sparsam verwendet werden. Nach dem Waschen der Paneele immer gründlich abspülen.

Jenseits der Reinigung, Baubesitzer sollten die Verkleidung regelmäßig auf Schäden inspizieren, Verschlechterung von Robben und Fugen, oder Akkumulation von Feuchtigkeit oder Trümmern im Hohlraum. Abhilfemaßnahmen wie das erneute Aufbringen von Dichtmittel an Gelenke können schwerwiegende Ausfälle oder Lecks verhindern. Testen Sie die Beschichtungsanhaftung 2-3 Jahre identifiziert potenzielle Bedenken frühzeitig. Gesamt, Die Aluminiumverkleidung erfordert im Vergleich zu anderen Baumaterialien nur sehr geringe Wartung. Es ist jedoch wichtig, die einfache Pflege der Langlebigkeit nicht zu vernachlässigen.

Kostenauswirkungen

Aluminiumverkleidung ist im Allgemeinen teurer als grundlegende Optionen wie Vinyl, Faserzement oder Holz. Aber es bietet einen hervorragenden Wert im Vergleich zu High-End-Metallen wie Zink, Kupfer- oder Edelstahl. Die anfängliche Investition wird über die Lebensdauer von Aluminium aufgrund ihrer Haltbarkeit und praktisch null Wartungsanforderungen ausgeglichen. Zu den Faktoren, die sich auf die Gesamtkosten auswirken:

- Art der Aluminiumlegierung mehr Premium -Legierungen kosten mehr

- Beschichtungsmethode, die teurer als Pulverbeschichtung anodieren

- Entwurfskomplexität komplizierte Formen und Perforationen fügen Kosten hinzu

- Barrierefreiheit Hochhausinstallation erfordert eine spezielle Ausrüstung

- Die Transportkosten steigen für abgelegene Projektorte

- Arbeitskomplexdesigns erfordern spezielle Installateure

Bei angemessen geplant, Die Aluminiumverkleidung kann sowohl ästhetische als auch Haushaltsziele für den Aufbau von Außenvertretern erreichen.

Erfahren Sie mehr über Aluminiumverkleidungspreise aus diesem Artikel: [Fabrikpreis] Ein Geheimnis in der Aluminium -Panel -Industrie

Lieferanten und Marken

Aluminiumverkleidungssysteme werden von Spezialisten für Metallherstellung hergestellt und international durch große Lieferanten zur Verfügung gestellt. Bekannte Aluminium-Verkleidungsmarken enthalten:

Alumideas – Bietet verschiedene Lösungen aus vielen Aspekten, einschließlich Auswahl des Aluminiumplattenmaterials, Auswahl der Oberflächenbehandlung, windabweisendes Design, Installationsdesign, Aluminium-Verbundplattenfassade, und so weiter.

Larson – bietet eine breite Palette von Paneltexturen wie perforiert, Rippen, oder zusammen mit farbenfrohen Oberflächen geprägt

Reynobond – Fertigt Aluminiumverbundtafeln mit Polyethylen- oder feuerresistenten Mineralkernen

Alucoil – Lieferungen vorab gefertigter Aluminiumspulen für die maßgeschneiderte Verkleidungsproduktion

VM Zink – Bietet umfangreiche dekorative Kassetten, Lamellen, und 3D -Tanell

Relevante Marken und erfahrene Lieferanten können geeignete Aluminium -Verkleidungslösungen für bestimmte Bauprojekte empfehlen

Die Aluminiumverkleidung bietet ein hervorragendes Gleichgewicht der Haltbarkeit, Ästhetik, Leistung und Kosten im Vergleich zu vielen anderen Außengebäude -Hautmaterialien. Aluminium ist leichter und starrer als Vinylverkleidung. Es bietet eine bessere Korrosionsbeständigkeit als verzinkter Stahl. Aluminiumblätter können in expressionstivere 3D -Formen im Vergleich zu Faserzement hergestellt werden. Und Aluminiumverkleidung bietet eine bessere Isolierung und Schallabsorption als Vollglasvorhangwände.

Einige gängige alternative Verkleidungsoptionen umfassen:

Faserzement – Langlebig und feuerbeständig, aber begrenzte Ästhetik.

Metall -Verbundwerkstoffe – Leicht, aber weniger starr als Aluminium.

Naturstein – Schön, aber sehr schwer und zerbrechlich.

Ziegel – Traditionelles Erscheinungsbild, aber schlechte Wärmeisolierung.

Glas – Verführerische Transparenz, aber höhere Kosten und schlechte akustische Isolierung.

Jedes Material hat Vor- und Nachteile. Aluminium fällt auf seine Vielseitigkeit und seine umfassende Leistung auf.

Design- und ästhetische Überlegungen

Die Aluminiumverkleidung bietet eine immense Designflexibilität für den Bau von Außenbereichen. Es kann in praktisch jede Form hergestellt und in unendlichen Mustern perforiert werden. Geschwungene Panels, Faltfassaden, und komplexe 3D -Formen sind alle möglich. Das Material braucht auch gut zu verschiedenen Texturen und Oberflächen wie geprägter, gebürstet, oder spiegelgefertigt. Wenn von hinten beleuchtet, Aluminiumverkleidung erzeugt atemberaubende visuelle Effekte.

Die aktuellen Trends sind die mutige Verwendung von Dunkelheit, Reflektierende Farbpaletten. Kontrastende vertikale und horizontale Panelanweisungen hinzufügen Dynamik. Kombinieren von Aluminium mit anderen Materialien wie Holz, Beton oder Stein erzeugt moderne gemischte Fassaden. Der Schwerpunkt liegt auf einer auffälligen Perforation und der Rückenbeleuchtung für ein Ätheral, glühender Blick. Organische Formen und abstrakte Texturen sind auch beliebte Richtungen für die Aluminiumverkleidung.

Technische Aspekte

Standardblattgrößen

- Dicke: 8MM bis 4,0 mm sind häufig

- Breite: 1000mm oder 1500 mm

- Länge: Bis zu 5m Panels möglich

Berechnung der erforderlichen Verkleidung

- Messen Sie die gesamte Außenwandfläche

- Hinzufügen 5-10% Extra für Abfall, Überlappungen, Kanten

- Berücksichtigung von Designfaktoren wie Gelenke, Perforationen

- Betrachten Sie Lieferbeschränkungen für große Panels

Umweltauswirkungen

- Aluminium ist 100% recycelbar ohne Eigenschaftenverlust

- Der recycelte Inhalt reduziert den Energieverbrauch durch Over 90% gegen Virgin Aluminium

- Pulverbeschichtungsbehälter verhindert die atmosphärischen Emissionen

Spezifizierer sollten recycelte Inhalte und Recyclierbarkeit maximieren, um die Nachhaltigkeit zu verbessern.

Fallstudien

Die Scherbe, London – Merkmale anodierte Aluminiumverkleidung mit fraktalen Formen und Winkeln, die Licht reflektieren. Diese markante Fassade definiert die Skyline in London.

Absolute Türme, Kanada – Wackelne Aluminiumbalkone mit einem wellenähnlichen Muster verleihen diesen Wohntürmen ein skulpturales Aussehen.

Ein zentraler Park, Sydney – Vorgefertigte Aluminiumpaneele mit organischen blumähnlichen Mustern integrieren dieses Gebäude mit dem umgebenden Grün.

Abschluss

Durch Aluminiumverkleidung Architekten und Bauherren eine unschätzbare Option für Außenhaut, die Ästhetik kombiniert, Leistung, und Langlebigkeit. Mit Umweltvorteilen wie Recyclierbarkeit und Energieeinsparungen durch Isolierung, Aluminiumverkleidung ist auch eine nachhaltige Fassade -Wahl. Fortschritte in der Fertigung ermöglichen bisher unmögliche Formen, Texturen, und Effekte. Mit informiertem Design, der von erfahrenen Fachleuten mit Metall -Kladding unterstützt wurde, Aluminium ermöglicht atemberaubende und dennoch pragmatische Gebäudeumschläge.

Häufig gestellte Fragen

Was ist der Zweck einer Aluminiumverkleidung??

Die Aluminiumverkleidung schützt das Gebäude vor dem Wetter und sorgt für eine dauerhafte Bereitstellung, wartungsarme und ästhetisch ansprechende Fassade. Es verbessert die Isolierung und ermöglicht gleichzeitig die Designfreiheit.

Wie lange dauert die Aluminiumverkleidung??

Mit minimalem Wartungsaufwand, Aluminiumverkleidung dauert vorbei 40-50 Jahre in den meisten Umgebungen aufgrund seiner Antikorrosionseigenschaften.

Was ist der Unterschied zwischen Fassade und Verkleidung?

Die Fassade bezieht sich auf das gesamte Äußere des Gebäudes. Verkleidung ist die externe Haut oder die Hüllkurve, die die Fassade bedeckt.

Was sind die Hauptüberlegungen bei der Gestaltung von Verkleidung?

Windlasten, Vibrationswiderstand, Wärmeausdehnung, gemeinsame Details, Feuchtigkeitsmanagement, Zugänglichkeit für die Installation/Wartung.

Alumideas ist ein Aluminium -Kladding -Hersteller in China. Wir bieten eine Komplettlösung für Ihre dekorativen Verkleidungsprojekte im Innen- und Außenbereich. Fordern Sie jetzt ein Angebot an!

Wir werden Sie innerhalb von 24 Stunden kontaktieren 1 Arbeitstag, Bitte achten Sie auf die E-Mail mit dem Suffix „@alumideas.com“.