Aluminum composite panels offer a combination of strength, mauroa, lightweight, and flexibility, making them suitable for a wide range of applications in the construction industry. They are often used for exterior wall cladding, signage, whakapaipai o roto, me etahi atu.

Tiwhikete

ISO 9001:2015 | SGS tiwhikete | He mea nui ki nga Tirotiro Kounga

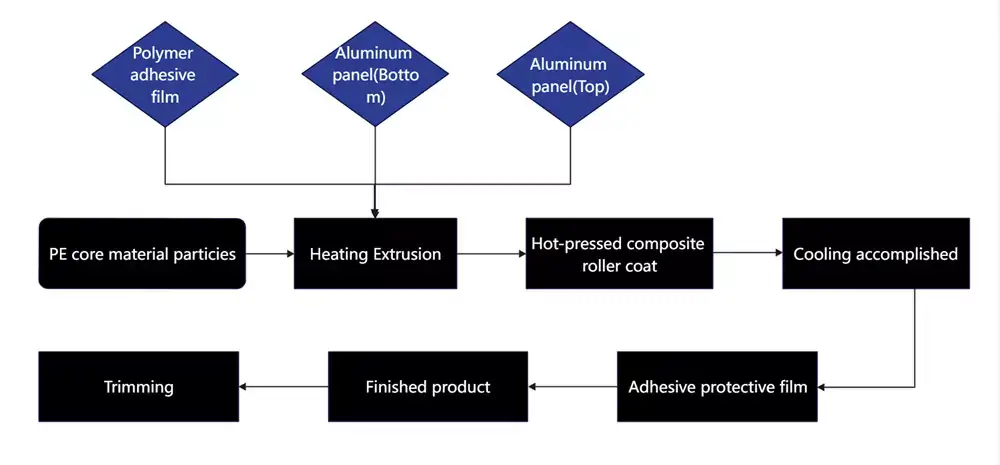

The aluminum composite panel is composed of two materials (metal and non-metal) with completely different properties. It not only retains the main characteristics of the original composition material (metal aluminum non-metal polyethylene plastic), but also overcomes the shortcomings of the two materials. It has many excellent material properties, such as weather resistance, parenga waikura, impact resistance, kore ahi, makuku-tohu, sound insulation, heat insulation and shock resistance; easy to process and shape, easy to handle and install. Therefore, it is widely used in all kinds of architectural decoration.

Mirror composite panel

Office composite panel

Fireproof composite panel

Composite panel curtain wall

The temperature difference is very small as the oven is 30cm in height. Horizontal baking, the temperature at every point of the product is almost the same. Coating at horizontal level, no extra manual coating is needed.

Since the coating and surface are non-granular and non-porous, contaminants cannot penetrate the surface.

The plate is baked at high temperature, the internal stress of the plate is released, and the deformation of the plate surface can be processed and formed after mechanical flattening.

Because the surface is smooth, there is no pollution. Dust and other pollutants on the surface can be washed off by rainwater.

Roller coating is a pressure printing coating, the whole coating film and surface are non-granular and free of micropores.

Due to the pressure coating of the plate, the force on the plate surface is uniform. The coat thickness deviation is 0.5μ.

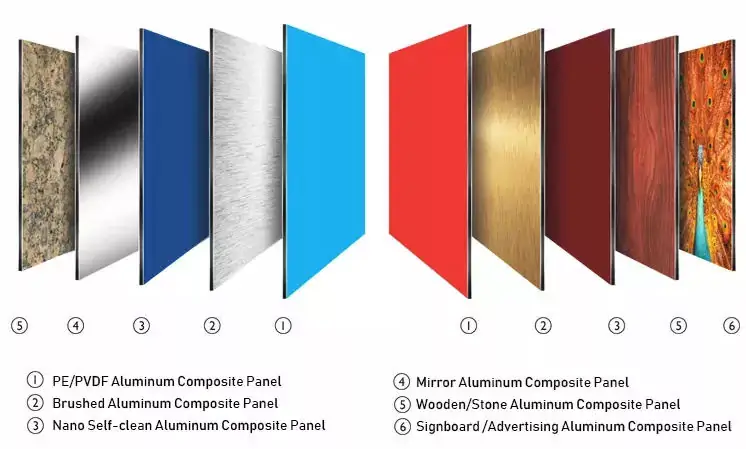

1. Aluminum composite panels for building curtain walls

The minimum thickness of the upper and lower aluminum plates shall not be less than 0.50mm, and the total thickness shall not be less than 4mm. The aluminum material should meet the requirements of GB/T 3880. Ko te tikanga, 3000, 5000 series of aluminum alloy plates should be used, and the coating should be fluorocarbon resin coating.

2. Aluminum composite panels for exterior wall decoration and advertising

The upper and lower aluminum plates are made of rust-proof aluminum with a thickness of not less than 0.20mm, and the total thickness should not be less than 4mm. The coating generally adopts fluorocarbon coating or polyester coating.

3. Aluminum composite panels for indoor application

The upper and lower aluminum plates generally use aluminum plates with a thickness of 0.20mm, the minimum thickness is not less than 0.10mm, and the total thickness is generally 3mm. Coatings are polyester or acrylic.

The aluminum composite panel is composed of two materials (metal and non-metal) with completely different properties. It not only retains the main characteristics of the original composition material (metal aluminum non-metal polyethylene plastic), but also overcomes the shortcomings of the two materials. It has many excellent material properties, such as weather resistance, parenga waikura, impact resistance, kore ahi, makuku-tohu, sound insulation, whakamahana wera, and shock resistance; easy to process and shape, and easy to handle and install. Therefore, it is widely used in all kinds of architectural decoration.

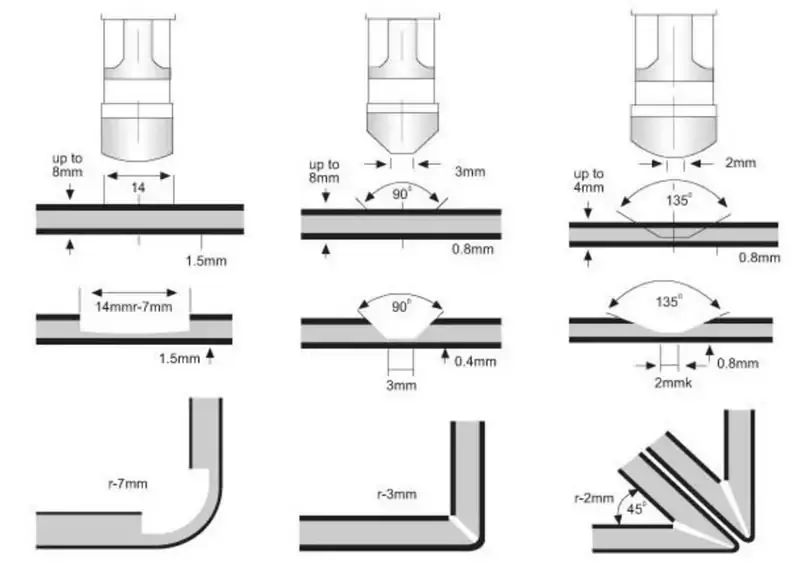

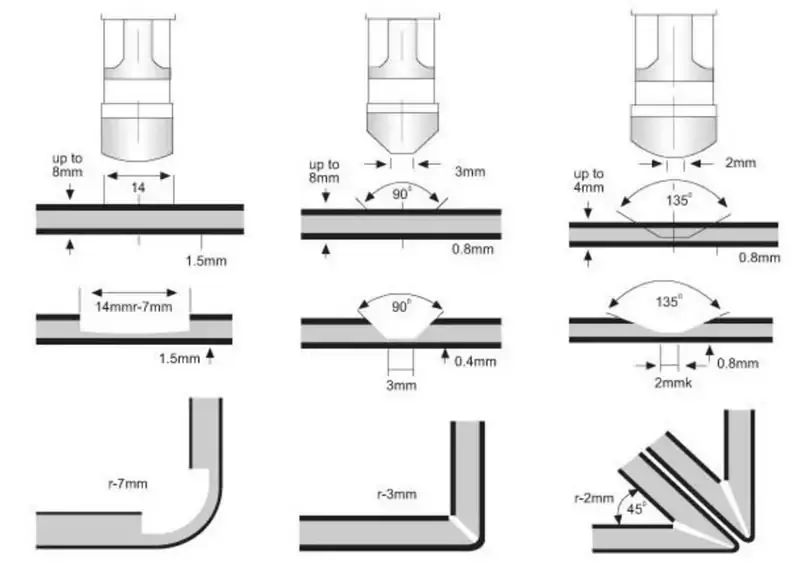

Aluminum-plastic panels can be cut, sawed, milled, punched, pressed, and bent with tools for processing wood or metal. It can be processed into various shapes according to the requirements of architectural decoration design, especially for arc, reverse arc, small radius fillet, inner and outer corners, and other shapes, which are incomparable with other decoration materials.

Ordinary aluminum products processing machinery and wood products processing machinery can be used for the processing of Alumideas composite panels without special equipment.

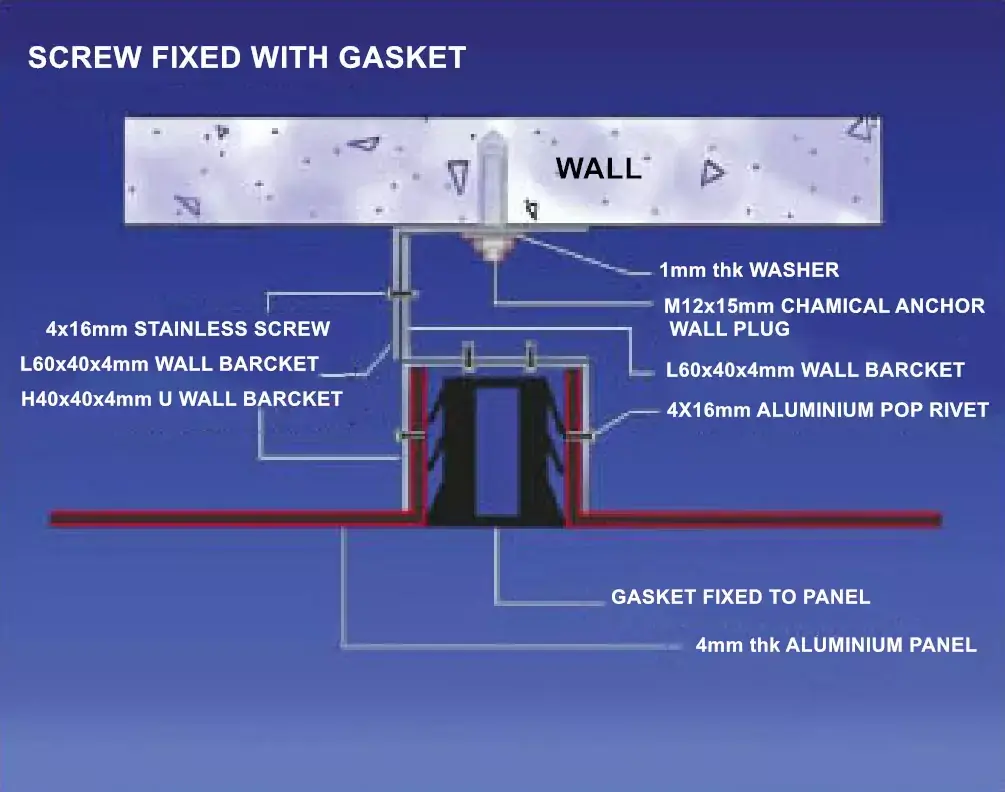

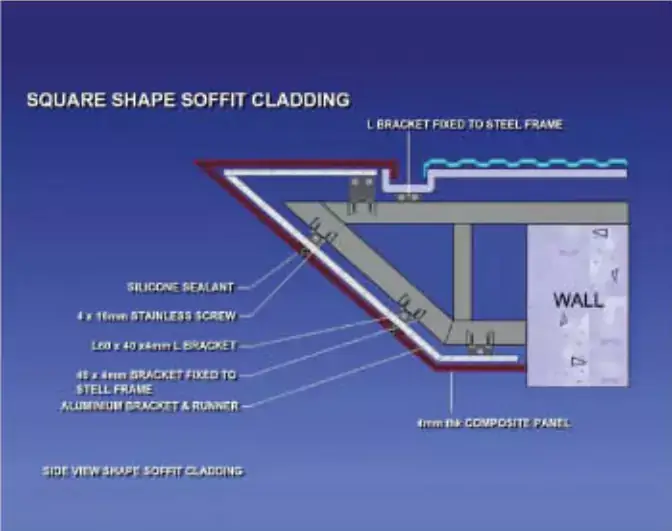

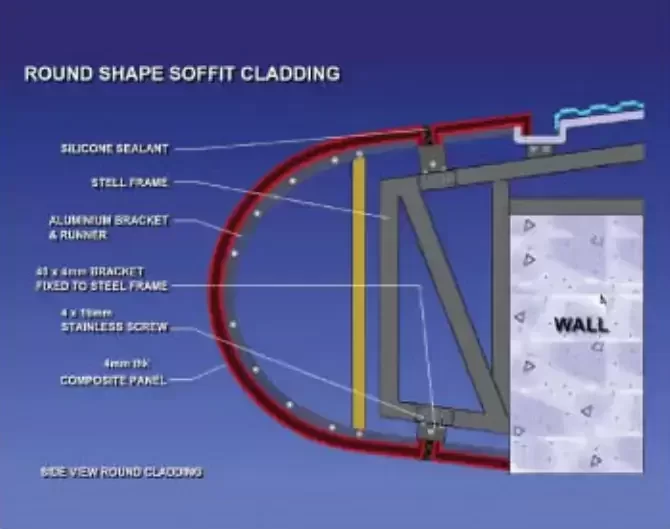

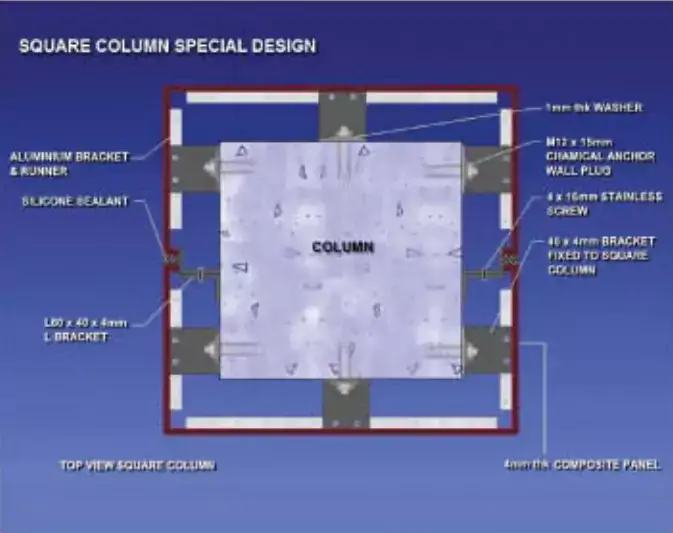

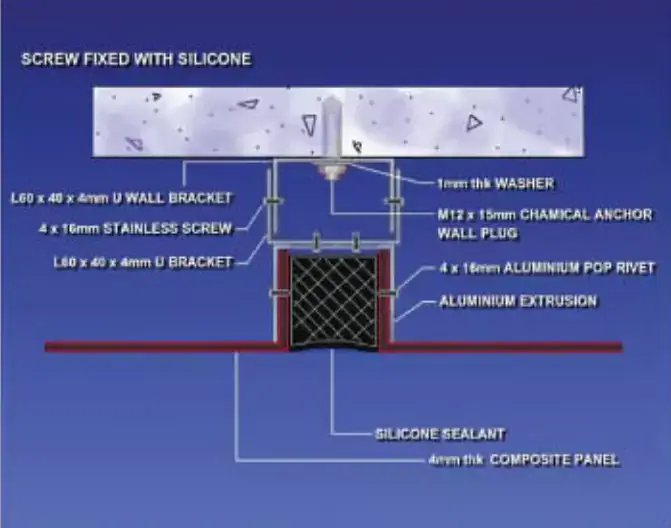

As a common material for building curtain wall, aluminum composite panel can be installed in different ways according to the shape of building exterior wall. The following are 5 common installation methods of aluminum composite panel:

Whakapotohia to huringa whanaketanga hua ma nga wiki (me etahi marama) me te whakaputa tauira a te roopu me te whakaoti i nga whakamatautau tohu i roto i nga ra. Ka taea te tukuna etahi tauira whakakikorua konumohe ki roto 3 nga ra.

Kei roto i ia korero te utu mo te wa tuturu me te tātari hoahoa. Ka arotakehia e matou to CAD 3D me te awhina ki te tautuhi i nga ahuatanga ka raru pea i te wa o te mahi whakangao., pnei i te whakakopa maha o nga pereti ahua motuhake me te whakairo tino tika.I tua atu, Ka taea e ta maatau roopu miihini tono mohio te korero mo to hoahoa ahurei, arotake i nga utu hokohoko, me te awhina i a koe ki te arotau i nga tuhi pepa konumohe me te whakarereke i nga hoahoa ma o maatau ratonga hoahoa korero.

Kua oti ia matou te raina taputapu rehu aunoa, oumu whakahaere pāmahana, Pūnaha wera LPG me te hangarau whakamaoritanga Tiamana. Ko te mata he mea hanga ki te paninga PVDF teitei mai i te PPG, DNT, AKZO, NIPPON me etahi atu kaihanga whakakikorua PVDF rongonui o te ao, me te whānuitanga o nga tae ka taea te whakarite i tetahi tae me to tauira tae

Kua mutu a Alumideas 60+ kaupapa o tawahi i roto i neke atu i te 30 whenua mo neke atu i te 10 tau. He mohio ki te hoahoa whakakikorua taiepa konumohe me nga tikanga whakaurunga i nga whenua rereke me te kaha ki te tuku tohutohu ngaio, hei whakatairanga i nga kaupapa miihini a nga kaihoko

Ka awhina matou ki a koe ki te karo i nga mahanga me te whakarato ki a koe he otinga roa me te utu whai hua i te waa me te putea.

Ko te Whakawhitinga Korero Tere ka awhina i a maatau ki te mahi pai atu ki a koe

Tikina he korero tere mai i a maatau kaitohutohu ngaio.

Ka whakapā atu matou ki a koe i roto 1 ra mahi, kia aro mai ki te imeera me te kumara “@alumideas.com”.