Project Introduction

A customer from Malaysia inquired about aluminum ceilings and aluminum perforated panels as decorative walls.

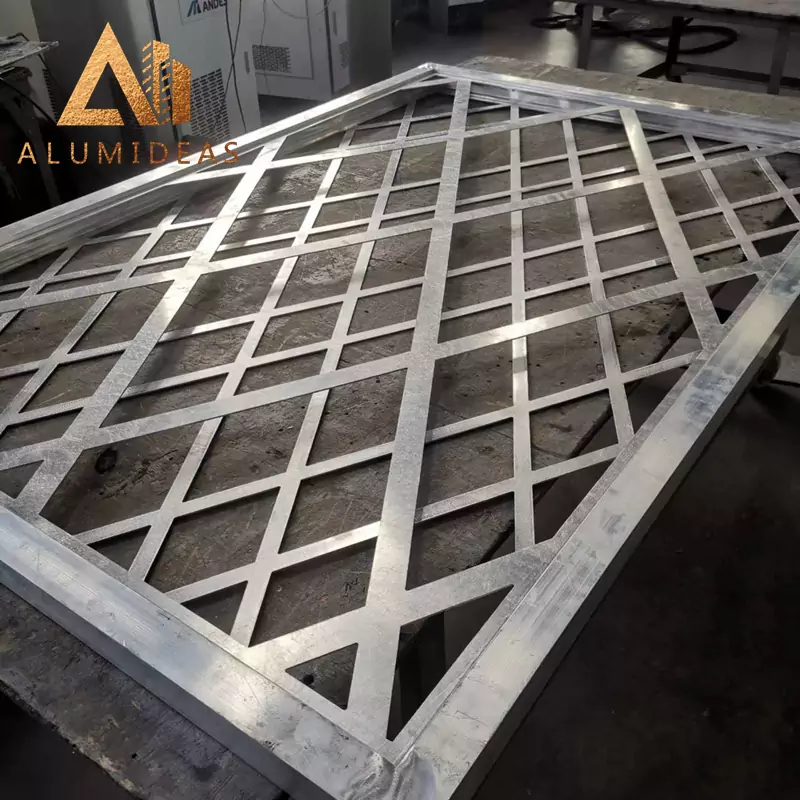

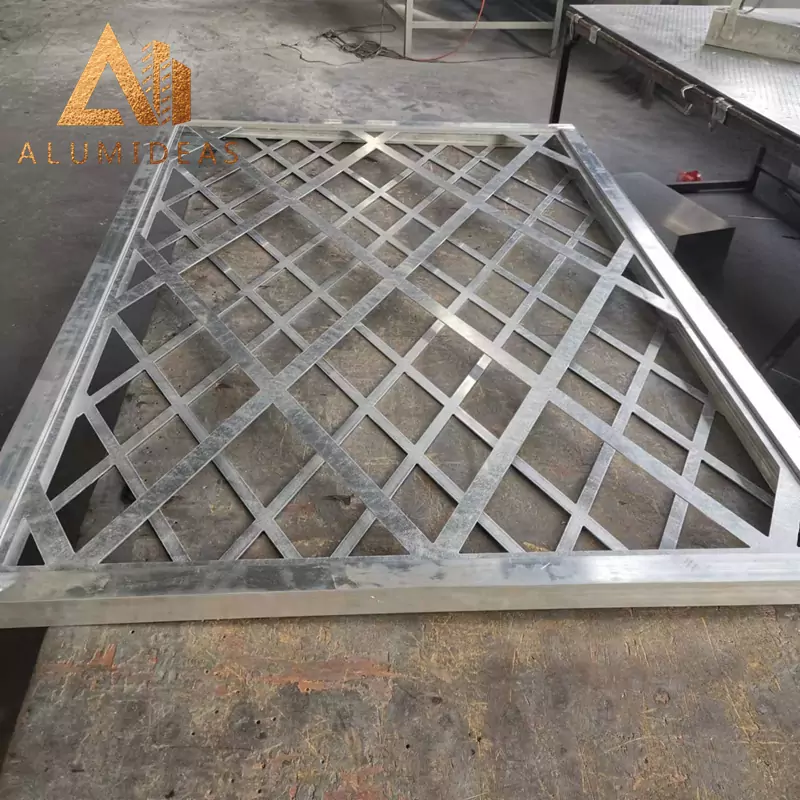

The aluminum ceiling is made of several aluminum profiles and they are welded together to form a square decorative ceiling, a total of 63 pieces.

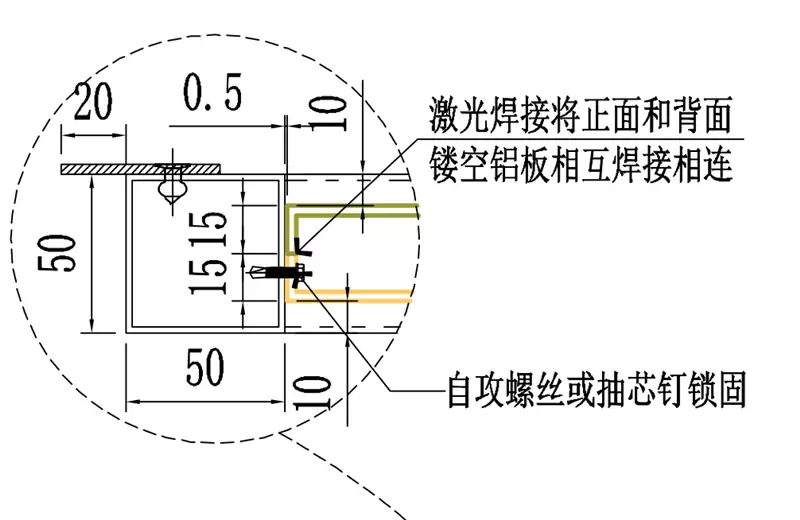

The aluminum decorative perforated wall panel, actually, it is made of two panels in the middle and a rectangular frame made of aluminum profiles. The design purpose is to use two panels to form a 3D effect of the perforation so that when the visitors walk by or stand there, they can have a different view.

Both the aluminum ceilings and aluminum perforated panels are manufactured in Alumideas’ factory and can be installed with simple tools.

Details of the panels:

1. Tae: white

2. Finish: PVDF on both sides

3. Rauemi: konumohe konumohe 1100 H24

4. Te matotoru: aluminum profile and frame: 1.4 mm; aluminum perforated panel: 3.0 mm + 3.0 mm

5. Type: customized panels used for ceilings and decorative wall

Difficulties

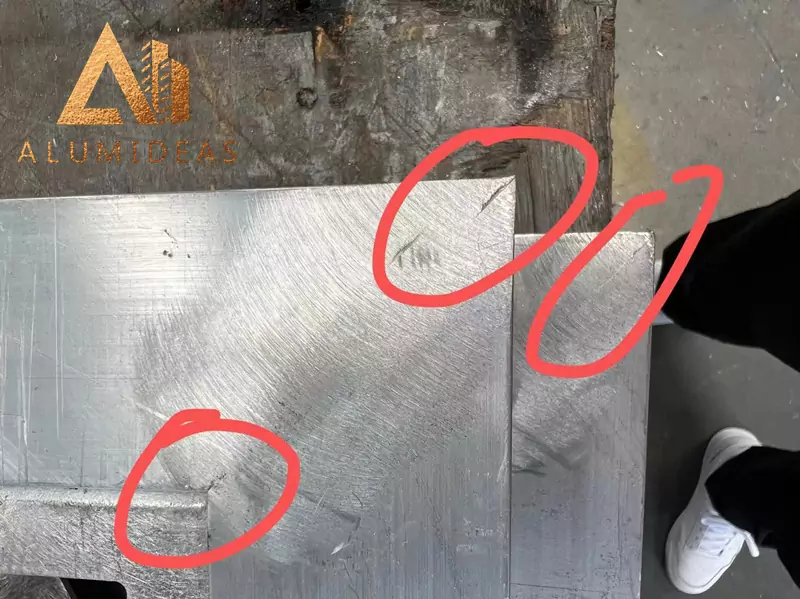

1. Two panels are easily deformed due to a large percentage of perforation and thus the 3D effect can’t be achieved.

2. There are visible cracks even after polishing.

3. There are holes for the screws to get in. But water will get in when doing cleaning before doing PVDF finish and the water still can’t totally evaporate even after several days.

Solutions:

1. Do some bending for the two panels, and weld the outer panel so that is can be fixed to the frame. For the inner panel, use rivets to fix it to the frame. This can enhance the strength of the panel.

2. Increase the welding penetration and use laser welding.

3. Drill two more holes at the sides of the ceilings and perforated panels to let the water out.

Photos in factory

Photos from customer