The aluminum plate with a thickness of 3.0mm is selected, the surface is made of PVDF three-coating, applying the famous American brand PPG. The total area is 1053 square meters.

Our wide range of aluminum cladding panels are manufactured in-house. All aspects are controlled including their quality and functionality. Tailor-make facade panels are available to finish your building or ceiling projects.

Alumideas is a supplier with rich project experience. In the face of different architectural styles of aluminum plate design around the world, Alumideas provides different solutions from many aspects, including aluminum plate material selection, surface treatment selection, wind-resistant design, installation design, and so on.

Drop Us A Line

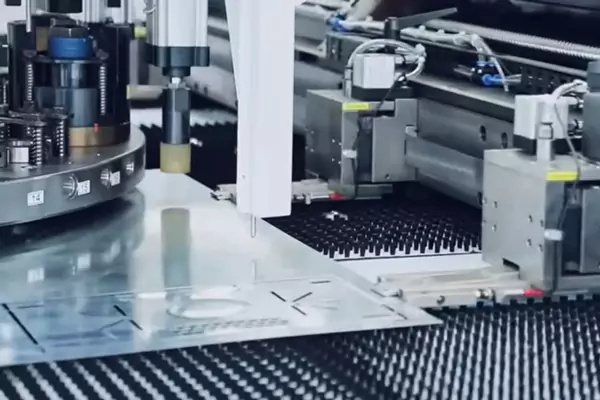

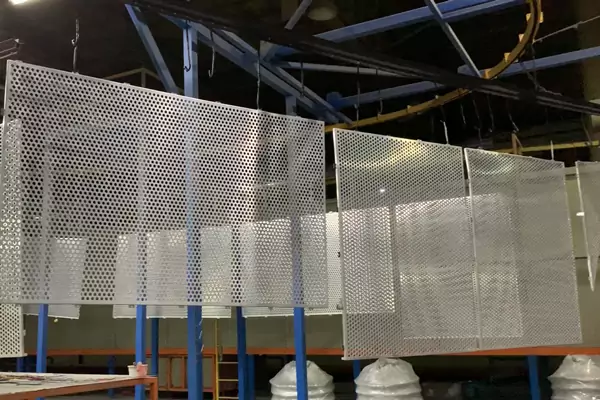

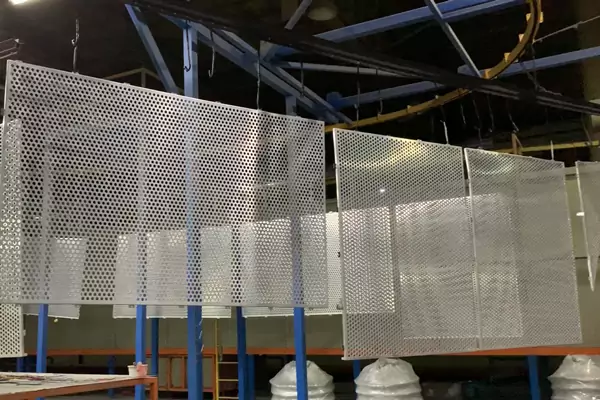

Alumideas has Laser cutting machines, CNC engraving machines, CNC cutting machines, CNC punching machines, Bending machines, Drilling machines, Welding machines, Automation fluorocarbon spraying lines and Automation powder coating lines etc. to meet various project’s demands.

JOTUN, PPG, AKZO, DNT, NIPPON are the famous powder brand suppliers we are cooperating with.

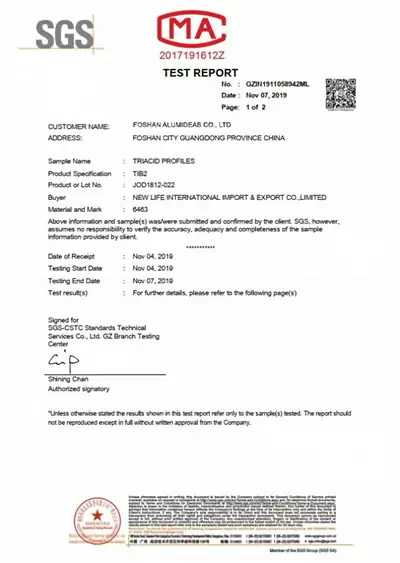

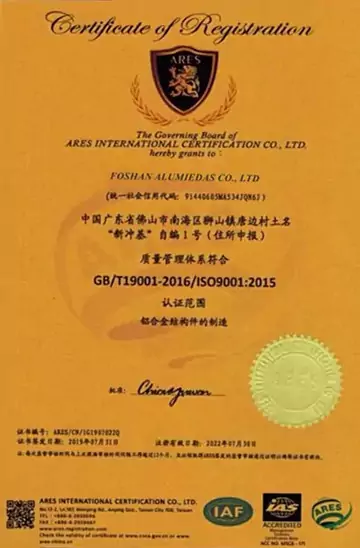

We have obtained ISO 9001:2015/ GB/T19001-2016 certification for production quality management system and CE, SGS qualified.

You can provide us the design and we generally will give you a solution in a week's time.

Alumideas has 60+ oversea projects in more than 30 countries within 12 years and has a well understanding of design styles of various countries.

Alumideas has Laser cutting machines, CNC engraving machines, CNC cutting machines, CNC punching machines, Bending machines, Drilling machines, Welding machines, Automation fluorocarbon spraying lines and Automation powder coating lines etc. to meet various project’s demands.

JOTUN, PPG, AKZO, DNT, NIPPON are the famous powder brand suppliers we are cooperating with.

We have obtained ISO 9001:2015/ GB/T19001-2016 certification for production quality management system and CE, SGS qualified.

You can provide us the design and we generally will give you a solution in a week's time.

Alumideas has 60+ oversea projects in more than 30 countries within 12 years and has a well understanding of design styles of various countries.

Alumideas, with 12+Years aluminum wall-cladding panel manufacturering and project experience. In the face of different architectural styles of aluminum panel design around the world, we provide different solutions from many aspects, including aluminum wall panels, interior decorative panel, aluminum ceiling, aluminum honeycomb panel and also aluminum composite panel.

ALUMIDEAS manufacturing program is developed to offer you quality aluminum panels of all kind at a friendly price.

This is an ideal solution for established aluminum panels project purchasers wanting to optimize and scale their brand reputation to serve more projects.

Each aluminum panel will be produced in strict accordance with national standards. During production, the product will be systematically inspected; after the production, the aluminum panel will be inspected again to ensure that the quality is good.

ALUMIDEAS has been manufacturing panels for over 12 years, producing panel materials according to international standards and inspecting goods to a high standard.

Due to the increased demand for aluminum panels, we added an additional CNC turret punching production facility and a horizontal powder coated line at the end of 2021.

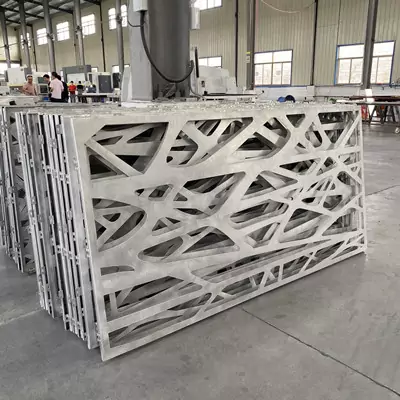

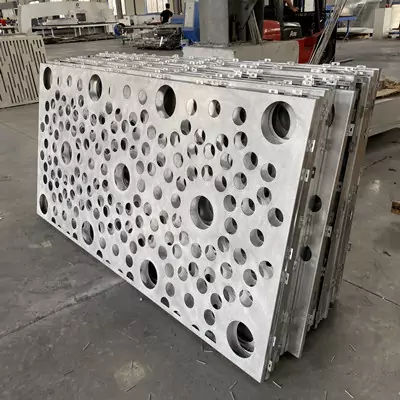

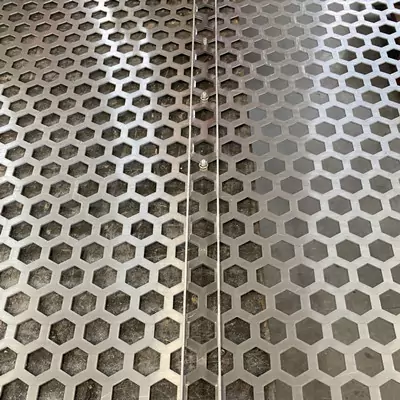

ALUMIDEAS currently manufacture more than 500 different patterns of high quality aluminum panels. We’d like to develop new patterns of aluminum panels every months.

We accept small quantity such as one or two square meters as test order, and aim to make it easy and affordable to for your trial order.

Whether you want to have your logo engraved on the aluminum panel or want to design it differently, we can help you

It’s not easy to know about all the aluminum panels production line before making order. Alumideas will show you every step on production with your order and online meeting will be available when necessary.

About us

As one of the leading aluminum panels manufacturers, Alumideas introduces some edge-cutting production facilities such as precise automatic CNC machine, laser machine for cutting, bending, punching, welding, drilling, digital carve and design. With a bunch of skilled technical persons and experienced workers, who will ensure the quality of aluminum panels, we can make complicated perforated aluminum panels and curtain walls with fast delivery and competitive price.

Years Of Experiences

For those who may not be familiar with importing aluminum panels, the following steps will be quite useful to know how to order and what is needed.

No matter you need the aluminum panels for your home, for a project or for other usage, these information is always needed: aluminum temper, surface treatment, thickness, color, pattern, width&length, amount, package.

If you don’t know much about the information, no worry, just ask our staff for help.

It’s necessary to make plan before moving forward. A detailed plan will be offered including the amount of panels needed and installation.

Sample will be prepared for customers to check its quality and appearance. Meanwhile, the drawing which will be sent via email must be signed and sent back before mass production begins.

Mass production will take about 10 to 20 days, depending on ordered amount of panels.

Delivery is always the most time-consuming part of a order, which usually will take more than a month. But no worry, Alumideas will always select the fastest delivery to save customer’s time and energy.

As installation is confirmed during the plan confirmation part, the only thing you need is an experienced team.

Any question will be answered by Alumideas enthusiastic staff and experts. Alumideas will be there whenever you are needed.

Check out what our clients said to ALUMIDEAS. ALUMIDEAS is not only a China aluminum panel manufacturer but your long-term partner. For different panel design models, we will tailor our services to best support your projects.

The aluminum plate with a thickness of 3.0mm is selected, the surface is made of PVDF three-coating, applying the famous American brand PPG. The total area is 1053 square meters.

For this project, the engineers chose customized patterns to make these aluminum plates unique. The 2,600-square-meter plates are divided into 12 categories, each with 6 patterns, and one aluminum plate for each pattern. And a symmetrical beauty is achieved through continuous repetition.

Coated with PVDF Kynar 500 in silver color, the 2.5mm corrugated panels decorate the office building with their distinctive aesthetic appearance. The total area of the project is about 2655㎡.

The three-dimensional structural panels support the outer wall, because the entire flat building has a more three-dimensional effect, making the building look more distinctive and easy to operate.

Alumideas has been a supplier of aluminum panel for 12 years and we encountered all kinds of questions. Below are the major concerns of customers before making an order.

Alumideas has obtained ISO 9001:2015/ GB/T19001-2016 certification for production quality management system and CE, SGS qualified.

Both are availabled, most of our clients make custom products in the style of their country.

Of course, but it is better to wait until the epidemic subsides. Now we support using ZOOM for online factory inspection.

Before making an order, the following details should be settled down:

About 20-25 days after details confirmed and deposit received.

Of course you can. World-famous brands such as JOTUN, PPG, AKZO, DNT and NIPPON are all available, but the price will be more expensive.

Usually the panels are packed with protective films and bubble films, and if needed, wood case is available, which is made of plywood and meets ISPM15 standards. But the cost of wood case is paid by customers.

Before making an order, the following details should be settled down:

Of course, but it is better to wait until the epidemic subsides. Now we support using ZOOM for online factory inspection.

About 20-25 days after details confirmed and deposit received.

Both are availabled, most of our clients make custom products in the style of their country.

Usually the panels are packed with protective films and bubble films, and if needed, wood case is available, which is made of plywood and meets ISPM15 standards. But the cost of wood case is paid by customers.

Alumideas has obtained ISO 9001:2015/ GB/T19001-2016 certification for production quality management system and CE, SGS qualified.

Of course you can. World-famous brands such as JOTUN, PPG, AKZO, DNT and NIPPON are all available, but the price will be more expensive.

No matter what style of aluminum panels you want, we can manufacture it according to our rich experience.

In particular, our equipment supports special craftsmanship, which makes the final products more diverse than most aluminum panels on the market.

We help you deliver quality and valuable aluminum panels for your projects, on time and on budget.

Choosing the right facade material for building exterior wall projects has always been the most concerned issue for engineers, designers and many other house owners. Different project budgets and designs mean different options for exterior wall panel materials. Experience tells that aluminum panel for wall cladding is usually a good choice.

Price has always been one of the first concerned things when people purchase aluminum cladding panels. In an order, it may not be the most important, because there are many other factors that will affect customers’ choice, but there is no doubt that in the end, all factors will be reflected in the price.

We receive many inquiries every day and answer thousands of questions about price. We get it.

In order to allow potential buyers, or people who are interested in aluminum sheets, to have a general understanding of the prices of our products, we write this article.

The first thing to note is that the price of aluminum panels will be adjusted according to the price of raw materials, and there are many other factors that will affect the specific price. The prices we provide below are for reference only, you can ask our staff for specific prices. All of the price is based on July 19, 2022. If the price changes greatly in the future, we will update it in time.

Before that, it should be noted that the following prices are for regular aluminum panels, such as square aluminum ceilings.

For some special-shaped plates, such as diamond panels, 3D special-shaped panels, or customized interior decorative panels, please ask our staff for quote.

Aluminum plates refer to the aluminum panel without doing any kind of surface treatment such as powder coating or PVDF spraying. The factors that affect the price are mainly the price of aluminum ingots, the thickness of aluminum sheets and also aluminum temper. As introduced in the article “Chemical Physical Properties of Aluminum”: 3003 grade plate is about 20% stronger than 1100 grade aluminum plate, meaning that when in production, the scrape rate will be higher, which will increase the price. Many customers want to buy aluminum plates and process them by themselves. We do not recommend doing so, because the aluminum plates are easily scratched during transportation, which will affect the effect of subsequent powder spraying or fluorocarbon paint.

There are so many options that will increase the price. For example, some may need thicker aluminium wall cladding panels in 4mm or even 5mm; some people need single-sided powder-coated aluminum punching panels, and some people need double-sided aluminum facade panels sprayed with PVDF paint.

Generally, under the same thickness, the price of powder coating panels will be lower than that of fluorocarbon paint. Precise price will be determined according to the specific requirements of the project.

The price of laser-cutting panels will be higher than that of ordinary engraving panels. This is because laser-cutting panels require more advanced laser engraving which will increase the accuracy and greatly shortens processing time, but the cost will increase accordingly.

There are many factors that affect the price, such as the price of the aluminum ingot, thickness, surface treatment, and special installation accessories.

Special installation accessories mainly refer to rib reinforcement that are thicker or need to be hollowed out the same as the aluminum panels ordered.

Usually, the thickness of the rib reinforcement is 1.0mm. If it needs to be thickened, the price will be $5 to $20 higher than the original. If the rib reinforcement need to be punched or perforated in order not to be seen from the front of aluminum panels, the price will be about $8 to $15 more expensive.

Again, the prices in the article are for reference only. At present, the price of aluminum ingots is erratic and at a relatively high price. If the price of aluminum ingots falls sharply, it is a good time to place an order. Don’t miss it.

If you want to know more, send an inquiry to us by mail or other means. Get quote now!

Get an instant quote from our professional consultants.

We will contact you within 1 working day, please pay attention to the email with the suffix “@alumideas.com”.

Quick Info Exchange Helps Us Serve You Better