Spray coating is a very important process in the manufacturing of aluminum veneer panel. This article will briefly introduce the powder spraying of aluminum veneer, including some basic information of powder coating, the process, features, the standard of film thickness, ens., so that we can better choose the most suitable products in future projects.

Afdeling van inhoud

Om seker te maak dat jy die inligting wat jy soek vinnig kan vind, klik net op die inhoudsgids hieronder.

The Basic Information of Powder Spraying

- Chemical Composition

The chemical composition of electrostatic powder spraying is mainly epoxy resin, polyester resin and pure polyester.

- Service Life

The service life is 5-10 years without discoloration.

- Top Ten Powder Brands

According to brand evaluation and sales, the top ten brands of powder coatings in 2022 were selected. The top ten are NIPPON, Wanan, Interpon, JOTUN, Tiger, PPG, Smoz, Sherwin-Williams, Huajia, and Axalta.

- The Thickness of powder coat

National standard for powder coating of aluminum veneer is 40u-120u.

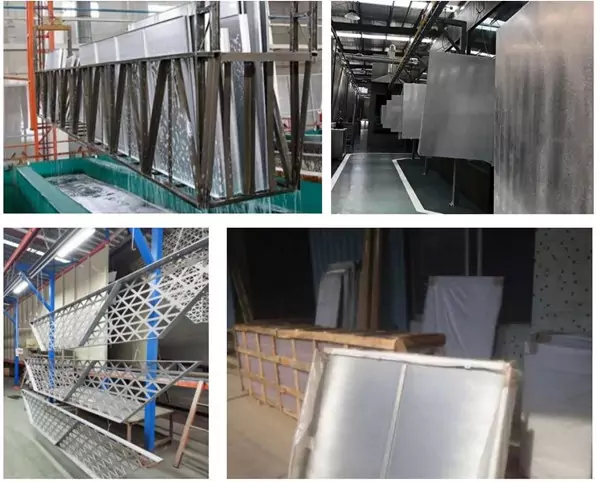

The Process of Aluminum Veneer Powder Spraying

The role of each link of the veneer surface spraying process is:

1.)Pre-treatment: ontvetting, dekontaminasie en chemiese behandeling om 'n verchroomde film te produseer, increase the bonding force between the coating and the metal surface and the anti-oxidation ability, which is beneficial to prolong the service life of the paint film.

2.) Primer: its role is to improve the penetration resistance of the coating, verbeter die beskerming van die substraat, and ensure the color uniformity of the topcoat.

3.)Topcoat coating: It is to provide the decorative color required for aluminum, protect the metal surface and enhance the anti-aging ability.

4.) Finishing paint: more effectively enhance the paint layer’s resistance to external erosion, protect the top paint coating, en maak die voorkoms meer aanskoulik.

5.)Genesende behandeling: Die driespuitbedekking benodig gewoonlik sekondêre verharding.

Features

Energy saving: reducing energy consumption by about 30% .

Less pollution: no organic solvent volatilization (do not contain the harmful gas such as toluene, xylene) in the paint .

High utilization rate of coating: can reach more than 95%, and the powder can be repeatedly used after recycling .

Good film performance: a one- time film thickness can reach 50-80 mikrons , the adhesion and corrosion resistance composite indicators are better than other paints.

High yield: before curing , can conduct secondary spraying.

Variety: the powder coating process is diverse. Commonly there are two kinds: electrostatic powder spray and dip plastic powder spraying.

Disadvantage: Not suitable for sunlight exposure. Long-term exposure will cause natural fading.

Toepassing & Warranty

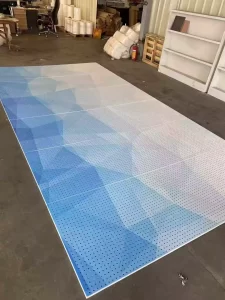

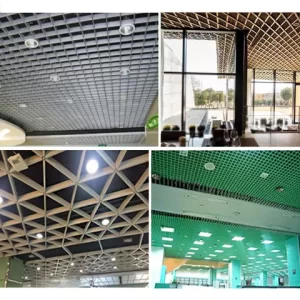

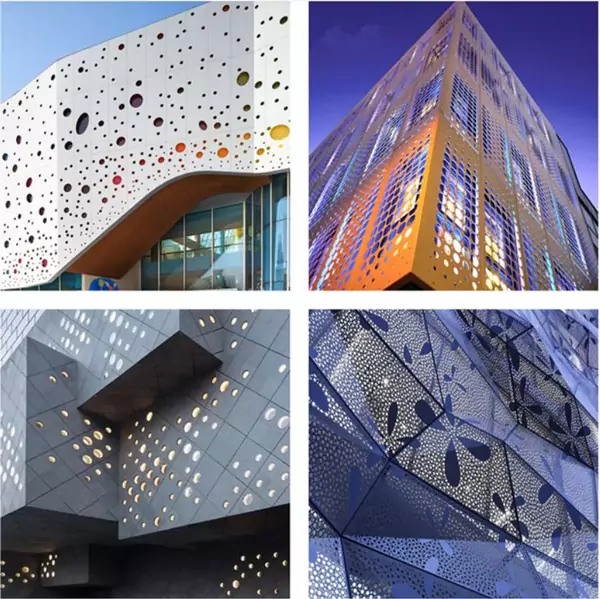

As powder coated aluminum veneer is not suitable for solar ultraviolet radiation, this kind of aluminum veneer is mainly used indoors, and the service life is 5-10 years without discoloration. Powder coating aluminum veneer can be used in offices, teaters, sports venues, shopping malls, household appliances and other occasions, and can be used as ceiling, wall or column covering, screen, TV background wall, ens.

The aluminum veneer has a good practical effect of decorative design. It can show different style, giving people a very high-end atmosphere and a very emotional feeling, which gives the audience some good visual impact and feeling.

Opsomming:

Electrostatic spraying is a common processing for aluminum sheets. Considering the practicality, appearance, price and cost, spraying has its unique advantages. We can choose the suitable surface treatment method according to our own needs.

Opsoek na 'n fasadeverskaffer vir u projekte?

Alumideas is 'n vervaardiger van aluminiumfasade in China. Ons bied 'n eenstop-oplossing vir jou binne- en buite dekoratiewe bekledingsprojekte. Vra nou vir 'n kwotasie!

Ons sal jou binne-in kontak 1 werksdag, let asseblief op die e-pos met die agtervoegsel "@www.alumideas.com".