El recubrimiento por pulverización es un proceso muy importante en la fabricación de paneles de chapa de aluminio.. Este artículo presentará brevemente la pulverización en polvo de chapa de aluminio., incluyendo alguna información básica sobre el recubrimiento en polvo, el proceso, características, el estándar de espesor de película, etc., para que podamos elegir mejor los productos más adecuados en futuros proyectos.

Sección de contenido

Para asegurarse de que puede encontrar la información que desea rápidamente, simplemente haga clic en el directorio de contenido a continuación.

La información básica sobre la pulverización de polvo

- Composición química

La composición química de la pulverización de polvo electrostático es principalmente resina epoxi., resina de poliéster y poliéster puro.

- Vida útil

La vida útil es 5-10 años sin decoloración.

- Las diez mejores marcas de polvos

Según evaluación de marca y ventas., las diez mejores marcas de recubrimientos en polvo en 2022 fueron seleccionados. Los diez primeros son NIPPON, Éste, Interpón, JOTÚN, Tigre, PPG, humo, Sherwin-Williams, Huajia, y axalta.

- El espesor de la capa de polvo

El estándar nacional para el recubrimiento en polvo de chapa de aluminio es 40u-120u..

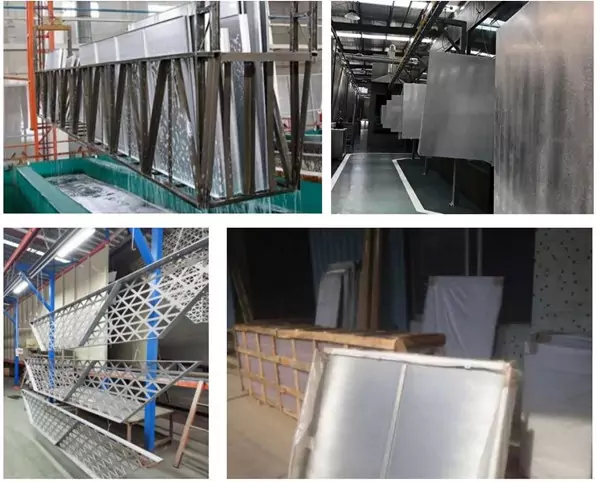

El proceso de pulverización de polvo de chapa de aluminio

El papel de cada eslabón del proceso de pulverización de la superficie del revestimiento es:

1.)Pretratamiento: desengrasar, descontaminación y tratamiento químico para producir una película cromada, aumentar la fuerza de unión entre el recubrimiento y la superficie del metal y la capacidad antioxidante, Lo cual es beneficioso para prolongar la vida útil de la película de pintura..

2.) Cebador: Su función es mejorar la resistencia a la penetración del revestimiento., mejorar la protección del sustrato, y asegurar la uniformidad del color de la capa superior.

3.)Recubrimiento de capa superior: Es para proporcionar el color decorativo requerido para el aluminio., Protege la superficie del metal y mejora la capacidad antienvejecimiento..

4.) pintura de acabado: mejorar más eficazmente la resistencia de la capa de pintura a la erosión externa, proteger la capa de pintura superior, y hacer la apariencia más vívida.

5.)Tratamiento de curado: El recubrimiento de tres pulverizaciones generalmente necesita un curado secundario..

Características

Ahorro de energía: reduciendo el consumo de energía en aproximadamente 30% .

Menos polución: sin volatilización de disolventes orgánicos (No contiene gases nocivos como el tolueno., xileno) en la pintura .

Alta tasa de utilización del recubrimiento.: puede llegar a más de 95%, Y el polvo se puede utilizar repetidamente después del reciclaje. .

Buena interpretación cinematográfica: un uno- tiempo que el espesor de la película puede alcanzar 50-80 micras , Los indicadores compuestos de adherencia y resistencia a la corrosión son mejores que otras pinturas..

Alto rendimiento: antes de curar , puede realizar fumigación secundaria.

Variedad: el proceso de recubrimiento en polvo es diverso. Comúnmente hay dos tipos: Pulverización de polvo electrostático y pulverización de polvo de plástico por inmersión.

Desventaja: No apto para exposición al sol.. La exposición prolongada provocará una decoloración natural..

Solicitud & Garantía

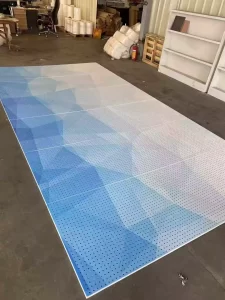

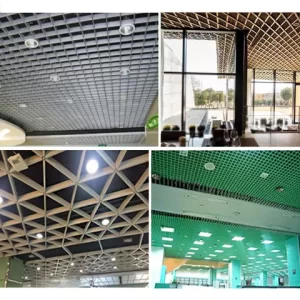

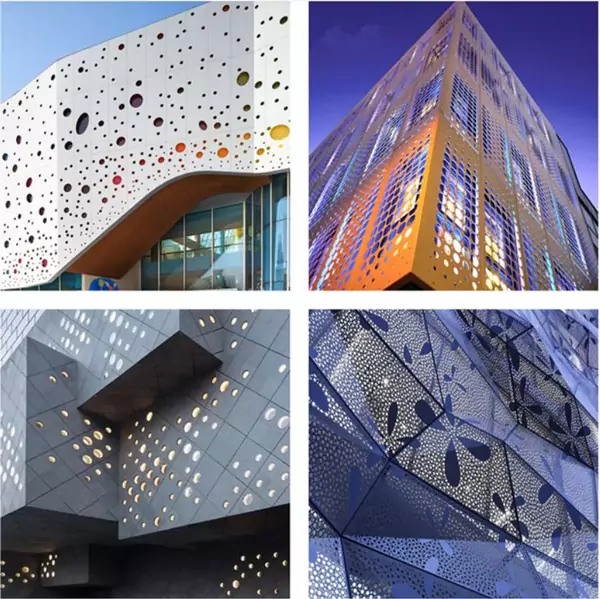

Como la chapa de aluminio con recubrimiento en polvo no es adecuada para la radiación solar ultravioleta, Este tipo de chapa de aluminio se utiliza principalmente en interiores., y la vida útil es 5-10 años sin decoloración. La chapa de aluminio con recubrimiento en polvo se puede utilizar en oficinas., teatros, instalaciones deportivas, centros comerciales, electrodomésticos y otras ocasiones, y se puede utilizar como techo, revestimiento de paredes o columnas, pantalla, pared de fondo de televisión, etc..

La chapa de aluminio tiene un buen efecto práctico de diseño decorativo.. Puede mostrar un estilo diferente, dando a la gente una atmósfera de muy alto nivel y un sentimiento muy emocional, lo que le da a la audiencia un buen impacto visual y sensación.

Resumen:

La pulverización electrostática es un procesamiento común para láminas de aluminio.. Teniendo en cuenta la practicidad, apariencia, precio y costo, La pulverización tiene sus ventajas únicas.. Podemos elegir el método de tratamiento de superficie adecuado según nuestras propias necesidades..

Buscando un proveedor de fachadas para sus proyectos?

Alumideas es un fabricante de fachadas de aluminio en China.. Brindamos una solución integral para sus proyectos de revestimiento decorativo interior y exterior.. Solicite una cotización ahora!

Nos pondremos en contacto con usted dentro 1 día de trabajo, por favor, preste atención al correo electrónico con el sufijo “@www.alumideas.com”.