This article is a brief introduction for welding process and the types of welding widely used in the aluminum panel industry.

Section of content

To make sure that you can find the information you want quickly, just click on the content directory below.

Common Knowledge of Welding

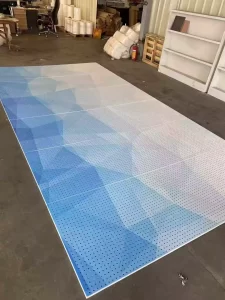

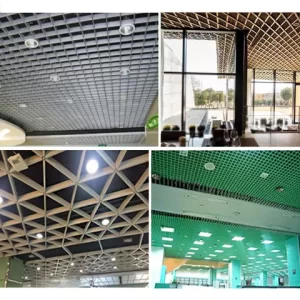

In the processing of aluminum veneer panel, the welding process is one of the essential links. There are many occasions where this process is used, such as the part where the aluminum plate is folded and intersected, the part where the lack of aluminum plate needs to be filled after the edge is folded, and the welding between the reinforcing rib planting nail and the surface of the aluminum plate, etc. If the welding process is not adopted, the installation process of the aluminum veneer will not be safe.

If welding is required during the design of the aluminum veneer, the position of the welding seam needs to be carefully checked. When welding, it is necessary to select the appropriate current, tungsten wire, tungsten needle and nozzle diameter according to the aluminum alloy material and the thickness of the aluminum plate. During the welding process, affected by the high temperature of the welding torch, the aluminum veneer will be deformed. Although the welding seam needs to be smoothed and putty treated, the effect after spraying is still not as good as the parts not welded. No reira, it should be avoided as much as possible.

The welding of aluminum veneer requires professional skilled workers to handle and operate. Welding is one of the indispensable processes in manufacturing aluminum veneer panel, and it is usually done according to customer requirements and engineering drawings. It is possible to achieve the desired shape through the welding process.

What is Welding?

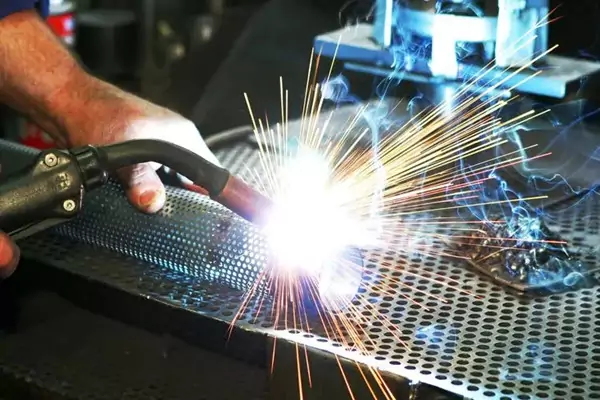

Wehenga, usually refers to the welding of metals. It is a forming method in which two separated objects are connected by atomic bonding force by heating or pressing, or both are used simultaneously.

According to the different process characteristics in the welding process, we mainly introduce the following two welding methods, namely ordinary welding and laser welding.Ordinary welding includes spot welding, continuous welding and discontinuous welding.

Spot Welding

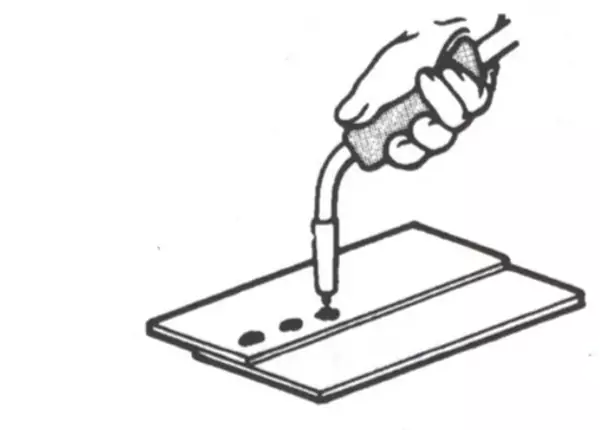

If the welding seam is connected by a separate welding spot, it is called spot welding. Spot welding refers to the welding method in which a cylindrical electrode is used during welding to form a welding spot between the contact surfaces of two overlapping work pieces. During spot welding, pressure is applied to make the work piece in close contact, and then the current is turned on. Under the action of resistance heat, the contact of the work piece is melted, and a solder joint is formed after cooling.

Continuous Welding

If a solder joint is connected to another solder joint, and there is no disconnection in the middle, that is called continuous welding.

Discontinuous Welding

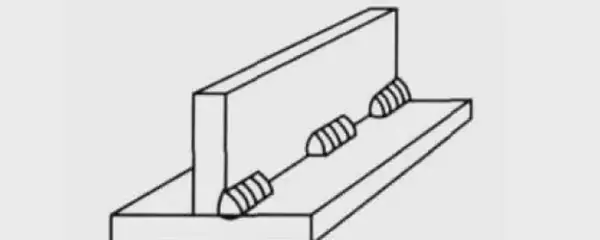

If the weld is joined by separate small sections, it is called segment welding or dispersion welding.

Discontinuous welding, or intermittent welding is a type of welding also known as flower welding. As the name implies, the welding seam is discontinuous during welding. It is used for the welding of non-important connectors that do not require full welding, or to reduce welding deformation and reserve welding deformation space. When both sides need be welded, the staggered intermittent welding method is generally used.

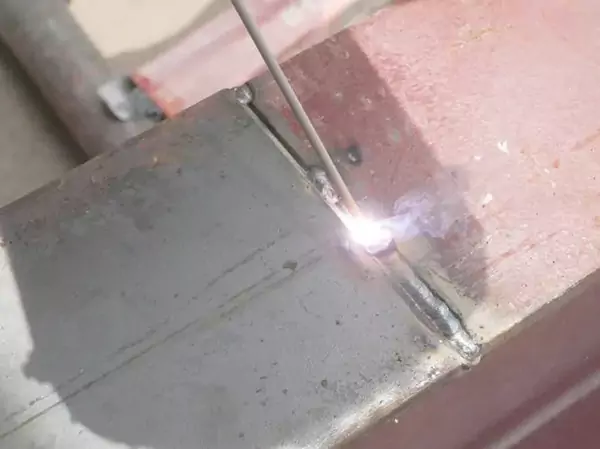

Laser Welding

At present, laser welding have obvious advantages of beautiful welding, high production efficiency, safety and environmental protection, and cost reduction. They are widely used in various industries. In the laser metal welding processing industry, it is widely used in the automotive industry in the form of stitch welding, body welding and parts welding.

Laser welding and electric welding can literally be seen as two different welding methods. See the sheet below of their specific differences.

Item | working principle | Related machines | Painga | Shortcoming |

Laser welding | Laser welding is an efficient and precise welding method that uses a high-energy-density laser beam as a heat source. | Handheld Laser Welding Machine Fiber Laser Welding Machine

| Easy to operate, fast welding speed, good welding effect, less welding consumables, high efficiency | Welding of highly reflective metals such as aluminum and copper is very difficult. Welding equipment is expensive |

Electric fehokotaki'anga | Using cylindrical electrodes to form solder joints between the contact surfaces of two overlapping work pieces | Hand arc welding machine Submerged arc welding machine CO2 gas shielded welding machine Plasma arc welding machine | 1. Good connection performance; 2. High rigidity of welded structure and good integrity. 3. There are many types of welding methods, and the welding process has wide adaptability | The welding deformation is relatively large, and it is easy to have pores. slow. The process is not as perfect as laser welding |

Notes:

Three things need paying attention to when welding aluminum veneer panel.

- Welding should be done once, and secondary welding should be avoided as much as possible, because secondary welding is likely to cause deformation of the aluminum veneer plate.

- The torch flame should not be too long, and it must be heated with a small fire, otherwise the aluminum veneer plate of the dispersant will be easily melted.

- The welding time should not be too long, because the melting point is too low and the time is too long, which will easily lead to the melting or thinning of the aluminum veneer panel, and the aluminum panel of the curtain wall is easy to leak during the pressing process.

Three things need paying attention to when welding aluminum veneer panel.

- Welding should be done once, and secondary welding should be avoided as much as possible, because secondary welding is likely to cause deformation of the aluminum veneer plate.

- The torch flame should not be too long, and it must be heated with a small fire, otherwise the aluminum veneer plate of the dispersant will be easily melted.

- The welding time should not be too long, because the melting point is too low and the time is too long, which will easily lead to the melting or thinning of the aluminum veneer panel, and the aluminum panel of the curtain wall is easy to leak during the pressing process.

Whakamutunga

This article is to introduce welding process in aluminum panel industry. Welding of aluminum veneer panel is an important process. If it is not welded, it will lead to deformation of aluminum veneer panel during logistics and transportation. So welding has a fixed effect for keep the aluminum veneer panel’s shape remaining unchanged.

Alumideas specializes in the production of decorative aluminum sheets, and related products that involve welding applications. If you have customers who need aluminum sheet products, you can contact us.

Kei te rapu i tetahi kaiwhakarato mata mo o kaupapa?

Ko Alumideas he kaiwhakanao hanga i Haina. Ka whakaratohia e matou he otinga kotahi-mutu mo o kaupapa whakakai whakapaipai o roto me waho. Tonoa he korero inaianei!

Ka whakapā atu matou ki a koe i roto 1 ra mahi, kia aro mai ki te imeera me te kumara "@ Www.alumideas.com".