Aluminum panels is a often-seen metal product used for both industrial and non-industrial applications. In most cases, it can be difficult to choose the right aluminum grade for your intended application. This article is to provide a brief introduction to the aluminum alloys used in the field of aluminum panels, or aluminum panel, so as to help people in aluminum panel industry to make their decision on the choice of aluminum alloy.

According to the naming of the national standard aluminum panels grades, aluminum panelss can be roughly divided into 8 series :

Alloy 1××× , Alloy 2×××, Alloy 3×××, Alloy 4×××, Alloy 5×××, Alloy 7×××, Alloy 8××× .

We have compiled a short breakdown of each of the grades’ properties in order to provide you with a brief understanding of their many uses.

① Alloy 1×××

What is ——

Alloy 1××× is industrial pure aluminum with the highest aluminum content among these 8 series, which is not less than 99.00%. Excellent elongation, tensile strength, plasticity and corrosion resistance are just some of its features. Its production process is not that difficult and the production technology is mature. Another advantage is its low price. However, the strength is low and it is easy to be deformed by compression.

Used for ——

Signs, billboards

Wall decoration

Kitchen utensils

Chemical equipment, electronic devices

At present, the 1100, 1050 and 1060 series of aluminum panels are widely used in the building decoration industry.

② Alloy 2×××

What is ——

It is an aluminum-copper alloy aluminum panel (Al-Cu), with copper as the main alloy element, which is between 3-5%. Alloy 2××× has high hardness, good machining performance, certain heat resistance and it can be heat treated. However, its corrosion resistance is poor.

Used for ——

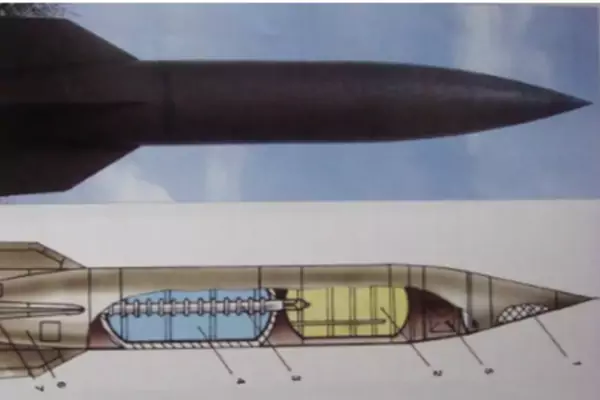

Industries and products that require high strength and high temperature resistance, such as

Aircraft structures

Missile components

Spacecraft parts,and ship bodies

③ Alloy 3×××

What is ——

It is an aluminum-manganese alloy aluminum panel (Al-Mn), also known as rust-proof aluminum panel, with manganese as the main alloying element, which is between 1.0-1.5%. Its strength is higher than that of the Alloy 1××× aluminum sheet, and it has good formability, weldability and corrosion resistance.

Used for ——

Industries with high requirements for anti-corrosion and anti-rust, such as:

Automobile manufacturing industry

Electronic manufacturing industry

Building decoration industry

At present, alloy 3003 and 3004 are widely used in the building decoration industry.

④ Alloy 4×××

What is ——

It is an aluminum-silicon alloy aluminum panel (Al-Si), with silicon as the main alloying element, which is usually between 4.5-6.0%. Alloy 4××× has high strength, low melting point, good corrosion resistance, good wear resistance, and small thermal expansion coefficient.

Used for ——

welding materials

⑤ Alloy 5×××

What is ——

It is an aluminum-magnesium alloy aluminum panel (Al-Mg), with magnesium as the main alloy element. This alloy possesses good processing and forming performance, corrosion resistance, welding performance, etc.

Used for ——

It is widely used in conventional industries because of its low density and lighter weight than other series of aluminum sheets. It is also commonly used in ship structures, aircraft fuel tanks, automobile fuel tanks, etc.

At present, 5052 aluminum panels are widely used in the building decoration industry.

⑥ Alloy 6×××

What is ——

It is an aluminum-magnesium-silicon alloy aluminum panel (Al-Mg-Si), with magnesium and silicon as the main alloying elements. It has medium strength, good corrosion resistance, good weldability and oxidation effect.

Used for ——

Industries and products with high requirements for corrosion resistance and oxidation resistance. Such as:

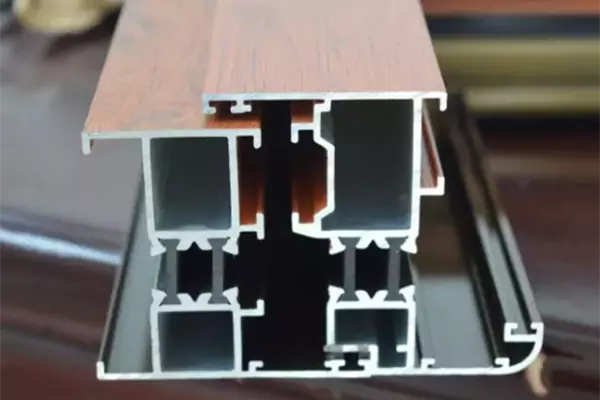

Window frame

Industrial profiles

⑦ Alloy 7×××

What is ——

It is an aluminum-zinc alloy aluminum panel [Al-Zn-Mg-(Cu)], with zinc as the main alloying element. It is a super hard aluminum alloy with good mechanical properties, wear resistance and fatigue resistance. As it has poor corrosion resistance so should be covered with other aluminum materials or other protective treatments.

Used for ——

Aerospace equipment materials, and also widely used in various machinery, molds and other processing fields.

Missile components

Industrial profiles

Industrial profiles

Among so many series, aluminum alloy 1×××, alloy 3××× and alloy 5××× are more commonly used aluminum alloy, among which the following tempers are most widely used:

1060H24, 1100H14, 1100H24, 3003H14, 3003H24, 5052H32

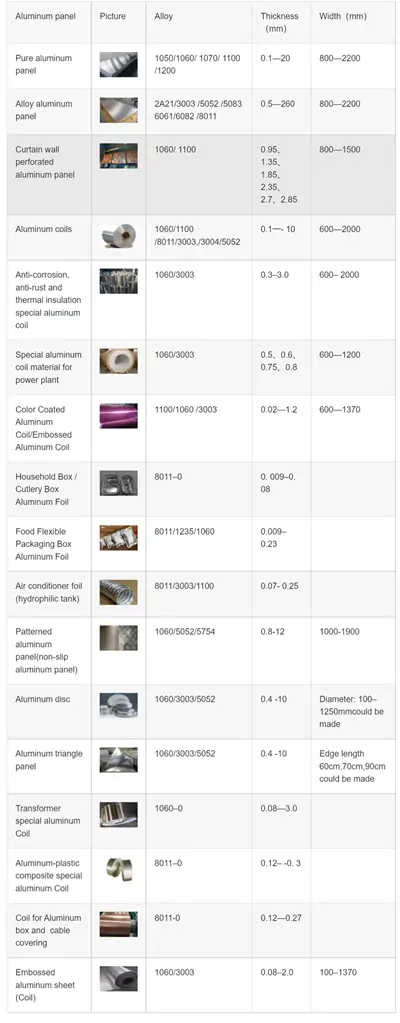

At the same time, we have made a brief summary of various specifications of aluminum panels, please see the following table

Summary of aluminum sheet sizes for different uses and alloys

Aluminum panel | Picture | Alloy | Thickness (mm) | Width(mm) |

Pure aluminum panel |  | 1050/1060/ 1070/ 1100 /1200 | 0.1—20 | 800—2200 |

Alloy aluminum panel |  | 2A21/3003 /5052 /5083 6061/6082 /8011 | 0.5—260 | 800—2200 |

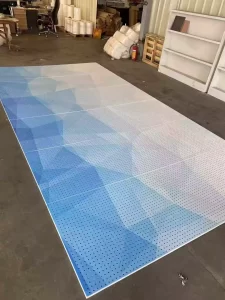

Curtain wall perforated aluminum panel |  | 1060/ 1100 | 0.95、1.35、1.85、2.35、2.7、2.85 | 800—1500 |

Aluminum coils |  | 1060/1100 /8011/3003,/3004/5052 | 0.1一- 10 | 600—2000 |

Anti-corrosion, anti-rust and thermal insulation special aluminum coil |  | 1060/3003 | 0.3–3.0 | 600– 2000 |

Special aluminum coil material for power plant |  | 1060/3003 | 0.5、0.6、0.75、0.8 | 600—1200 |

Color Coated Aluminum Coil/Embossed Aluminum Coil |  | 1100/1060 /3003 | 0.02—1.2 | 600—1370 |

Household Box / Cutlery Box Aluminum Foil |  | 8011–0 | 0. 009–0. 08 | |

Food Flexible Packaging Box Aluminum Foil |  | 8011/1235/1060 | 0.009–0.23 | |

Air conditioner foil (hydrophilic tank) |  | 8011/3003/1100 | 0.07- 0.25 | |

Patterned aluminum panel(non-slip aluminum panel) |  | 1060/5052/5754 | 0.8-12 | 1000-1900 |

Aluminum disc |  | 1060/3003/5052 | 0.4 -10 | Diameter: 100–1250mmcould be made |

Aluminum triangle panel |  | 1060/3003/5052 | 0.4 -10 | Edge length 60cm,70cm,90cm could be made |

Transformer special aluminum Coil |  | 1060–0 | 0.08—3.0 | |

Aluminum-plastic composite special aluminum Coil |  | 8011–0 | 0.12– -0. 3 | |

Coil for Aluminum box and cable covering |  | 8011-0 | 0.12—0.27 | |

Embossed aluminum sheet (Coil) |  | 1060/3003 | 0.08–2.0 | 100–1370 |

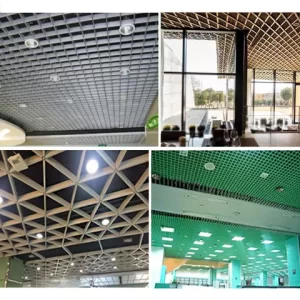

At Alumideas , our products are widely used for exterior and interior in architecture and building, shopping mall, hospital, metro station, railway station etc. For multifunctional advantage like ventilation, decoration, partition, excellent in lights transmission and so on.

If any requirement for Aluminum decorative panel please contact us ! We will offer the best quote and service !

Looking For a Facade Supplier For Your Projects?

Alumideas is a aluminum facade manufacturer in China. We provide a one-stop solution for your interior and exterior decorative cladding projects. Ask for a quote now!

We will contact you within 1 working day, please pay attention to the email with the suffix “@www.alumideas.com”.