Bending is an indispensable step in the production process. Its main functions are to enhance the rigidity of the aluminum plate, increase the practicability and aesthetics, and at the same time facilitate installation and splicing. The following will introduce the bending principle and process of aluminum plate in detail. Upang matiyak na maaari mong mahanap ang impormasyon na gusto mo nang mabilis, click mo lang yung content directory sa baba.

Bending principle

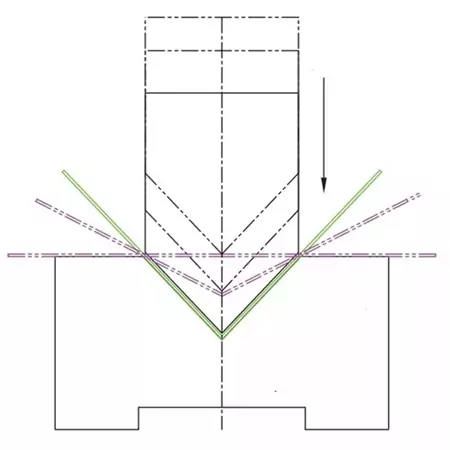

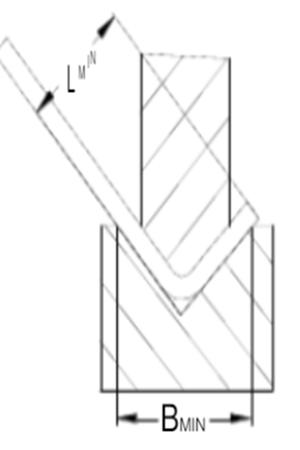

Aluminum plate bending is a forming process in which the metal aluminum plate first undergoes elastic deformation under the pressure of the punch or die of the bending machine, and then enters the plastic deformation. In the initial stage of plastic bending, the aluminum sheet is free to bend. As the punch or die presses the aluminum plate, the aluminum plate and the inner surface of the V-shaped groove of the die are gradually abutted, and the radius of curvature and the bending arm are gradually reduced. The three points are close to full contact, and a V-shaped bend is completed at this time. When bending, since the metal aluminum plate will be elastically deformed by the extrusion of the bending die, the contact point between the aluminum plate and the die will slip with the progress of the bending process.

Interference phenomenon when aluminum plate is bent

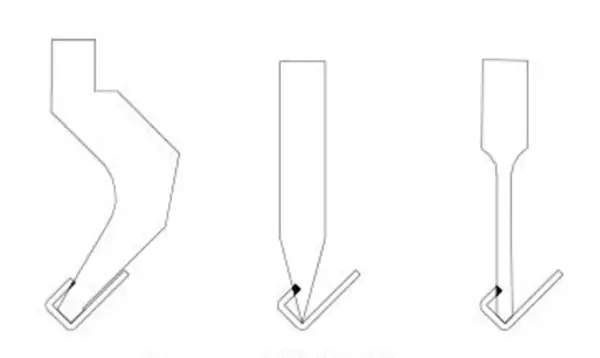

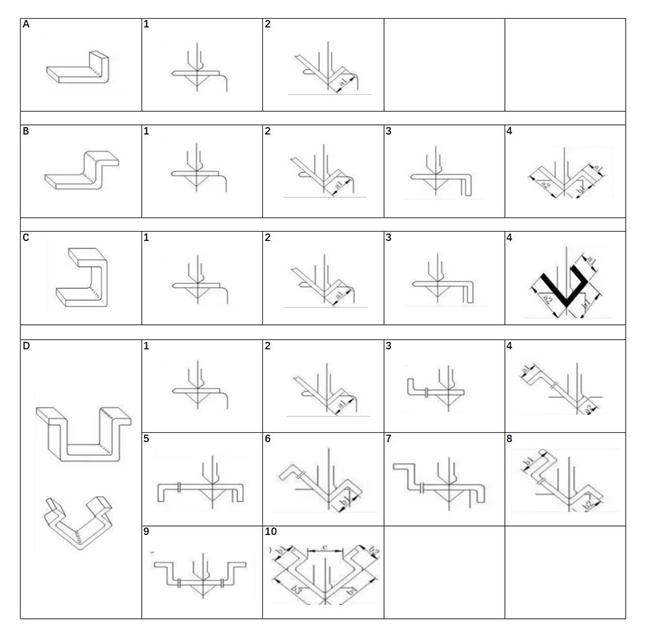

In the actual bending process, the primary consideration is whether there is interference in the bending design of the aluminum plate, as shown in the following figure

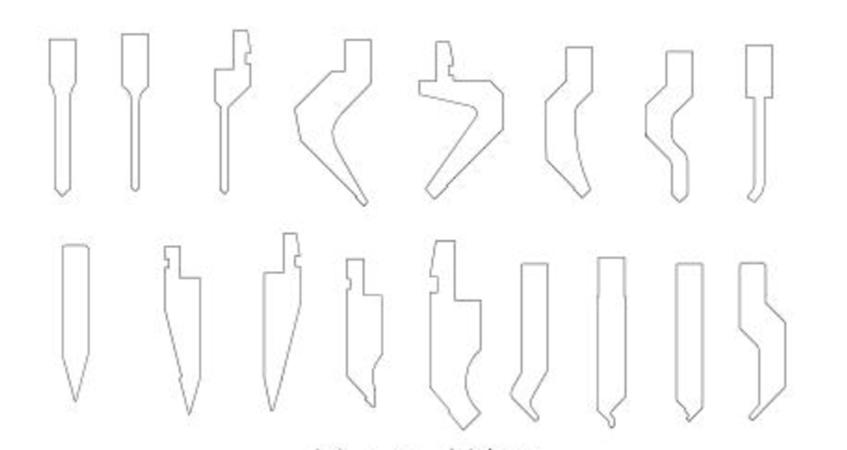

In order to fit different types of aluminum sheet bending designs, it is necessary to use a suitable bending knife

Deformation analysis of aluminum plate during bending

During the bending process of the workpiece, bending deformation will inevitably occur. The influencing factors are obtained by analyzing the change law of the aluminum plate during the bending process, so as to compensate in the process design.

(1) Deformation area analysis

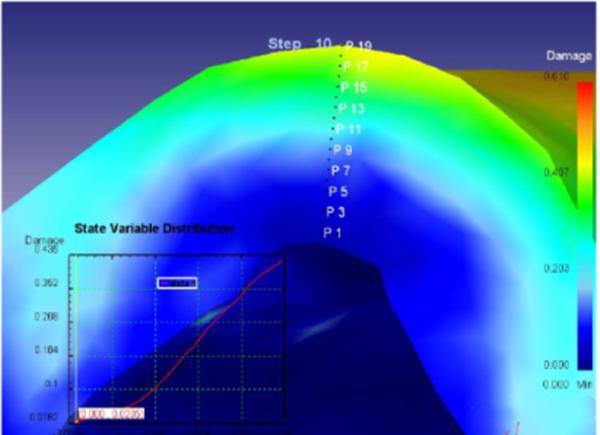

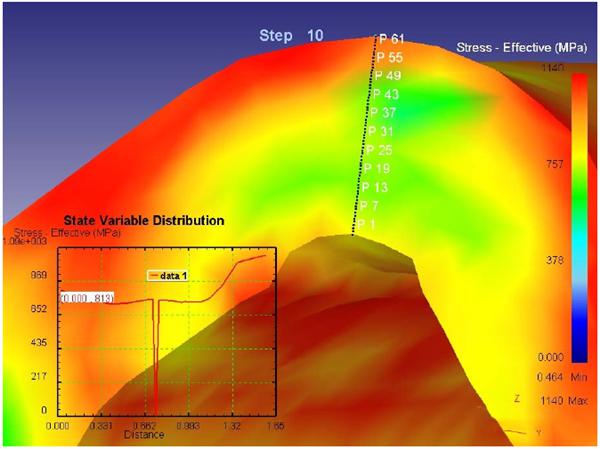

By performing CAE analysis on the failure analysis, stress and strain of ordinary aluminum plates, the main concentrated areas of deformation of aluminum plates can be obtained.

It can be obtained from the failure analysis that the parts that are prone to fracture or tear during the bending process are mainly concentrated in the outer skin area. It can be obtained from the strain analysis that during the bending process, the strain gradually decreases from the bending inner skin to the neutral layer, and gradually increases from the neutral layer to the outer skin. At the bending outer skin, the strain reaches the maximum value. It can be obtained from the stress analysis that during the bending process, the stress is mainly concentrated in the bending skin area.

Sa buod, the stress and strain of the workpiece are mainly concentrated in the outer skin area during the bending process, so deformation and tearing occur uniformly.

(2) Bending deformation factor of aluminum plate

Localized thinning of the bend. When the workpiece is bent and deformed, since the center layer gradually moves inward in the direction of plate thickness, the area of the outer layer’s tensile thinning area gradually becomes larger, and the inner layer’s compression thickening area gradually decreases, so the outer layer’s thinning area is larger than the inner layer’s thickening area. , the aluminum plate will appear local thinning in the direction of the plate thickness. Since the width of the workpiece is generally much larger than the thickness of the plate, the width direction can be approximately regarded as not deformed during bending. According to the principle of the constant volume of plastic deformation, the material that flows due to the thinning of the workpiece increases the length direction.

The local thinning phenomenon is related to the relative bending radius (r/t). The smaller the relative bending radius, the more serious the bending thinning phenomenon, and the bending thinning phenomenon cannot be completely eliminated.

Tala: Bending springback

The aluminum plate is divided into four stages in the bending process, elastic deformation, elastic-plastic deformation, plastic deformation and elastic deformation recovery. In the process of plastic forming, the aluminum plate is always accompanied by elastic deformation. When the external load is removed, the plastic deformation keeps the elastic deformation and disappears, so that the bending shape of the aluminum plate is different from the size of the mold, and a rebound phenomenon occurs. Through CAE analysis, the relationship between springback radius, springback angle and aluminum plate, mold and material properties is obtained.

There are many factors affecting the springback phenomenon. In addition to the above factors, it is also related to the bending radius, bending center angle, mold opening, aluminum plate shape, friction coefficient, bending correction force, bending method and other factors.

Influencing factors of bending R angle

What are the factors that may affect the bending R angle of the aluminum plate? There are aluminum plate thickness, aluminum plate material, bending upper die fillet, bending lower die, bending pressure, atbp. I analyze it one by one based on personal experience, hoping to be beneficial to readers.

Aluminum-aluminum sheet: Different aluminum sheets have different bending coefficients of the same thickness, and there are slight differences, which proves that the material characteristics affect the bending fillet. One property of a material is its ability to resist bending, which may directly affect the bend radius.

Bending upper die fillet: the normal bending die fillet is not greater than 1, and the minimum bending fillet cannot be less than 1, which has little effect on the unrequired bending fillet. For special needs aluminum plate bending fillet is less than 1 or far greater than 1, it is not determined by the bending upper die fillet. Kaya nga, the rounded corners of the bending die directly affect the bending radius.

Bending pressure: The thicker the aluminum plate, the greater the ability of the material to resist bending deformation. At this time, the pressure needs to be adjusted. The bending pressure cannot be increased indefinitely, and it needs to be adjusted to a suitable pressure. The bending pressure is proportional to the thickness of the aluminum plate and inversely proportional to the width of the lower die slot. In actual bending, the thickness of the aluminum plate is set, and the width of the lower die slot is selected according to the thickness of the aluminum plate. Kaya nga, the bending pressure is assumed to be a constant by other factors. The bending radius can be used without considering the pressure factor.

Bending lower die: The width of the slot of the lower die is related to the thickness of the aluminum plate, and there is a corresponding relationship. In practice, the greater the thickness, the greater the bend fillet. The thickness of the same aluminum plate, the bending fillet of different bending die notch is also different. Facts have proved that the bending die notch is an important factor affecting the bending radius.

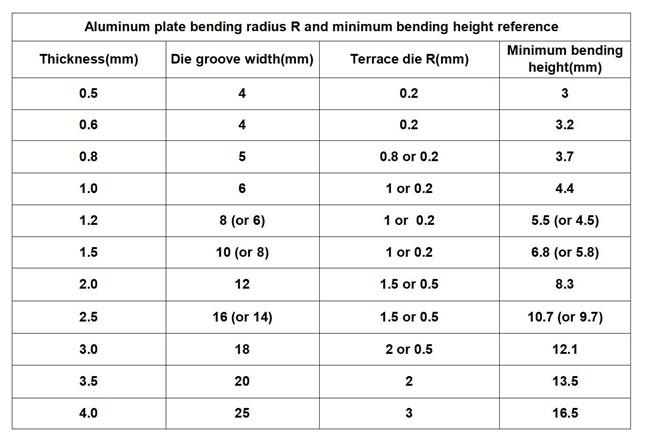

The minimum bending height of aluminum plate bending

In order to ensure the smooth installation and beautiful effect of some aluminum plate projects, the required folding height is small, and the minimum bending height of the aluminum plate needs to be verified when the drawings are reviewed.

Tala:

- The minimum bending height includes 1 unit material thickness

- When the V-shaped bend is an acute angle, the minimum bending height needs to be increased by 0.5mm

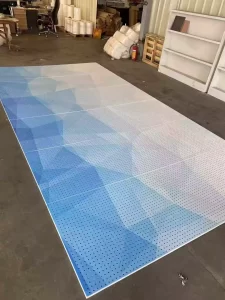

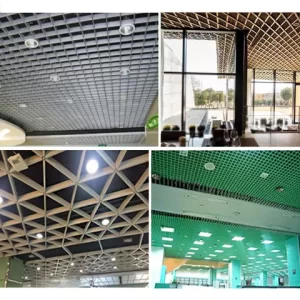

Common aluminum bending shapes

Naghahanap Para sa isang Facade Supplier Para sa Iyong Mga Proyekto?

Alumideas ay isang aluminyo facade tagagawa sa Tsina. Nagbibigay kami ng isang one stop na solusyon para sa iyong panloob at panlabas na pandekorasyon cladding proyekto. Humingi ng quote ngayon!

Makikipag ugnayan kami sa iyo sa loob ng 1 araw ng pagtatrabaho, paki pansin po sa email na may suffix "@www.alumideas.com".