This article mainly introduces the grinding process in the aluminum veneer panel production.

Untuk memastikan Anda dapat dengan cepat menemukan informasi yang Anda butuhkan, kami telah menyiapkan direktori konten. Ketika Anda mengkliknya, Anda akan dibawa ke bagian yang sesuai.

Type of Grinding:

There are two types of grinding: rough grinding and fine grinding.

Rough grinding: the function of rough grinding is to polish off the junction of the welded aluminum decorative panel and the junction of arc rolling panels, so as to ensure the beauty of the interface of the work piece. The tool used for rough grinding is a grinder which is equipped with a special cutting and grinding disc for aluminum.

This kind of grinding wheel adopts mixed abrasives and additives, which can effectively prevent the aluminum scraps generated due to excessive temperature during the regrinding process of the aluminum panel from adhering to the grinding surface of the abrasive tool, thereby reducing the work efficiency and even destroying the grinding surface of the work piece. Using this kind of grinding wheel can reduce the deformation of the work piece and the blocking of the grinding wheel itself, reduce the temperature of the grinding area, and prevent the work piece from being deformed due to excessive heat.

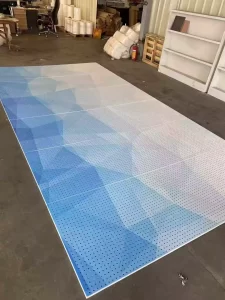

Unpolished aluminum interface

Polished aluminum interface

Type of Grinding:

Fine grinding is the last process of the aluminum veneer panel before spraying. The workers use 100-mesh sandpaper to grind the surface of the panel. 100-mesh sandpaper is enough to remove oil, dust, dll.. on the surface, and can also grind a relatively flat surface.

The function of fine grinding:

- To grind the surface of the aluminum plates and remove the burrs, minyak, dust, dll.. on the surface of the panel.

- The surface of the not-burnished aluminum panel will be rough, and it needs to be sanded to obtain a relatively flat surface. Karena itu, the surface roughness of the aluminum panel can be reduced by grinding.

- To enhance the adhesion of the coating. Umumnya, the aluminum plates needs to be burnished again before spraying.

Aluminium plate being polished

Catatan:

Before grinding, workers will apply a layer of emulsified grinding fluid to the position that needs to be sanded. It is a lubricating, anti-rust, anti-corrosion, cooling, water-insoluble product.

You may ask why do the fluid is needed? In fact, the grinding process is a process of rapid rotation, as long as it is in contact, a high temperature of about 400 to 1000℃ will be generated. At high temperature, if the grinding surface is not protected, the material will be seriously deformed and burned, which will damage the grinding wheel, so it is necessary to use this emulsion to remove the heat, so as to protect the aluminum panel and the machine.

The Requirements for Grinding in Alumideas

When grinding, the workers of Alumideas must do the following things:

- Carefully read the design drawings to understand the grinding requirements of the welding parts in the work piece.

- Check carefully before grinding to determine the parts that need to be burnished. The parts to be burnished are generally: welds, defective parts on the surface, sharp points, burrs, edge teeth, and the defective parts on the surface of the aluminum decorative panel depend on their severity, only coarse sandpaper can be used. or fine sandpaper.

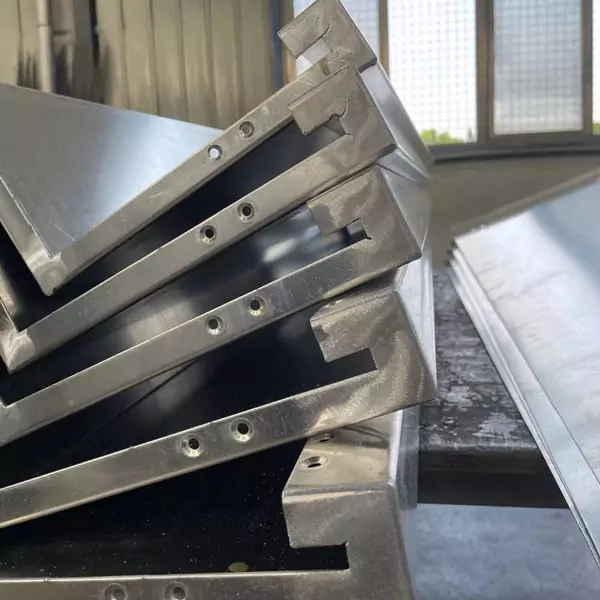

- The grinding wheel used for the welding seam can only be ground flat, leaving a rough and fine grinding allowance, and no dents or deep wear marks are allowed.

- For sharp points and burrs, use a file to sharpen them; edge tooth gaps should be ground according to specific conditions to ensure a good visual effect.

- When grinding the work piece, you must operate in the specified area, and pay attention to mutual protection to avoid accidental injury or damage to the work piece.

- When grinding, the work piece should be stable, and it should not be against hard objects.

- After the aluminum plate is burnished, it should meet the following requirements: clear intersecting line; smooth and consistent rounded corners; no tumor marks on the edge of the plate flange; no tooth shape; the corner part has no special requirements for arc transition, and there are no scratches and grinding marks on the surface.

Menggiling

Kesimpulan

This article briefly introduces the process of aluminum veneer panel grinding from these aspects: grinding type, notes and Alumideas’ requirements for grinding.

For aluminum decorative panel grinding, not only experienced workers for grinding are needed but also welding masters are needed as welding is the former step of grinding. The premise of grinding is to see whether the welding is standard. If it is not standard, no matter how good the workers who grind the aluminum panel are, the panel will not pass the quality examination.

The welding and grinding workers of Alumideas are all equipped with many years of work experience, which will ensure the smooth production of aluminum panels of every order.

Below is a short video of grinding that you can watch to get an overview of the grinding process.

Mencari Pemasok Fasad Untuk Proyek Anda?

Alumideas adalah produsen fasad aluminium di Cina. Kami memberikan solusi terpadu untuk proyek pelapis dekoratif interior dan eksterior Anda. Minta penawaran sekarang!

Kami akan menghubungi Anda di dalam 1 hari kerja, harap perhatikan email dengan akhiran “@www.alumideas.com”.