Polyester paint is one of the common surface treatments for aluminum plate. This article mainly introduces the polyester paint in the spraying process of aluminum veneer panel. To make sure you can quickly find the information you need, we have prepared a content directory. When you click on it, you will be taken to the corresponding section.

Section of content

Introduction of Polyester Paint

Polyester paint consists of three components: main paint, thinner and curing agent: the main agent is a styrene solution of unsaturated polyester, and there are also initiators (also known as curing agents, hardeners) and accelerators. The unsaturated double bond in the main chain of the saturated polyester undergoes a radical copolymerization reaction with an ethylenic monomer (styrene) as an active solvent, and is cured to form a film.

Polyester paint uses polyester resin as the main film-forming material. Polyester paint is also called Unsaturated polyester paint. It is a multi-component paint and a thick paint made of polyester resin as the main film-forming material. The paint film of polyester paint is plump, and the layer is thick and the surface is hard. Polyester paint also has varnish varieties, called polyester varnish. Polyester paint needs to be cured during the construction process, and the amount of these curing agents accounts for one-third of the total amount of paint. These curing agents are also called hardeners, and their main ingredient is TDI (toluene diisocyanate).

However, these free TDI will turn yellow. Not only the surface of the material painted with polyester paint will turn yellow, but also the adjacent walls will turn yellow, which is a major disadvantage of polyester paint

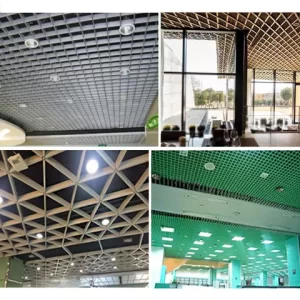

Normally, the service life of polyester paint on the surface of aluminum veneer is 5-12 years. This service life will not only be affected by the quality of the polyester paint itself, but also the application position of the aluminum veneer. If the polyester painted aluminum veneer is installed indoors, the service life will be relatively long. While if it is outdoors, the service life will be relatively short. Alumideas will ensure the good quality of polyester paint, and to avoid paint peeling, discoloration which will damage the customers’ experience.

The Steps of Polyester Paint Spraying

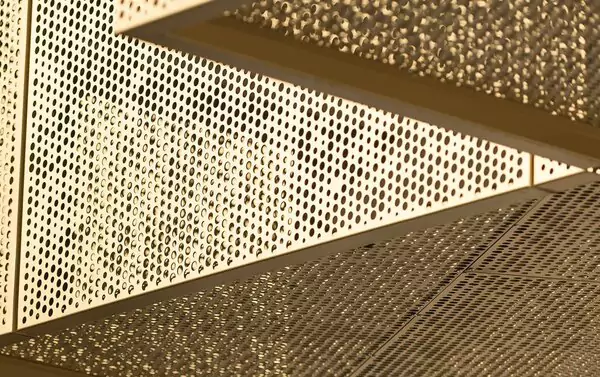

The first step of polyester paint spraying on aluminum veneer is to paint the primer coating. Primer coating is the primer decoration of the aluminum veneer substrate. This layer is used as an inherent protection, mainly aims to improve the penetration resistance of the coating when further finishing. The aluminum veneer material is protected by primer painting. In this way, the surface effect of the material can be stabilized, the finishing effect has good uniformity, and the adhesion effect between the topcoat material and the metal plate can be improved. Generally, the thickness of the primer is controlled at about 5-10 microns.

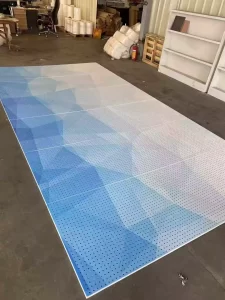

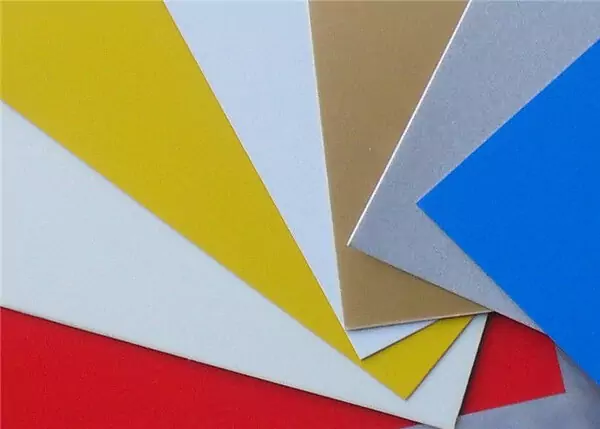

The second step is topcoat coating, that is, the polyester paint layer. The polyester paint is sprayed on the surface of the aluminum veneer in the corresponding color according to the design requirements, which is an important step in decoration. The topcoat coating can not only add decorative effect to the appearance, but also beautify the aluminum veneer material, making it more suitable for the needs of building decoration. At the same time, polyester paint can prevent the aluminum veneer material from directly contacting the outside air, so that it is not attacked by acid rain, pollutants, etc., and delays the aging speed of the material. Generally, the thickness of the topcoat is required to be controlled at about 20-30 microns.

The third step of varnish coating. The main reason for the varnish treatment is to increase the anti-invasion ability of the coating to the external environment, to better protect the integrity of the topcoat coating, to enhance the gloss effect of the surface. The thickness of the varnish coating is generally required to be around 5-10 microns.

The next step is curing treatment, that is, to further consolidate the three-layer coating, so that the aluminum veneer has a better decorative effect. This step requires keeping the aluminum alloy material in the curing furnace for high temperature consolidation, and the temperature is controlled between 180-250 degrees Celsius. Different aluminum veneer manufacturers will control the temperature and time to a certain extent according to the materials they produce.

Advantages of Polyester Paint

Polyester paint has many advantages. Not only is the color very rich, but also the thickness of the paint film is large. It can be sprayed two or three times, and it can completely cover the material of the base layer. Therefore, polyester paint can be directly brushed on the aluminum panel. The material requirements are not high. The comprehensive performance of polyester paint film is excellent. Because of the use of curing agent, the paint film has higher hardness, hard wear resistance, high richness, resistance to damp heat, dry heat. Also, as polyester paint has acid and alkali oils, solvents and various chemicals, the insulation of the aluminum veneer panel sprayed with polyester paint will be greatly increased.

Disadvantages of Polyester Paint

The steps of formulating polyester paint are troublesome, and the ratio of accelerator and initiator is strictly required. After the paint is mixed, the activation period is short, and it must be completed within 20-40 minutes, otherwise it will gel and be out of use. In addition, its repair performance is also poor, and the damaged paint film has imprints after repair. Polyester paint needs to be cured during the construction process, and the amount of these curing agents accounts for one-third of the total paint. These curing agents are also called hardeners, and their main component is TDI (toluene diisocyanate). These free TDI will turn yellow. Not only the surface of the material painted with polyester paint will turn yellow, but also the adjacent walls will turn yellow, which is a major disadvantage of polyester paint. At present, yellow-resistant polyester paints have appeared on the market, but they can only be “yellow-resistant”, and cannot completely prevent yellowing.

In addition, free TDI beyond the standard will cause harm to the human body. The harm of free TDI to the human body is mainly sensitization and stimulation. The international limit for free TDI is controlled below 0.5%. Alumideas will strictly conform to international standards to avoid adverse effects on customers.

Summary:

This article briefly introduces one of the paints used for aluminum veneer panel spraying through the perspective of advantages and disadvantages of polyester paint. Reading through the article, it can be seen that polyester paint is not the first choice for spray paint. You can read the powder coating and PVDF articles of Alumideas to better understand the surface treatment of aluminum panels and choose the most suitable coating method for your aluminum veneer panel.

Looking For a Facade Supplier For Your Projects?

Alumideas is a aluminum facade manufacturer in China. We provide a one-stop solution for your interior and exterior decorative cladding projects. Ask for a quote now!

We will contact you within 1 working day, please pay attention to the email with the suffix “@www.alumideas.com”.