At ألوميدياس, we pride ourselves on our 12+ سنوات من الخبرة في التصنيع عالي الجودة ألواح الجدران المصنوعة من الألومنيوم. Our skilled technical team and experienced workers ensure the quality of our aluminum panels, enabling us to create complex perforated aluminum panels and curtain walls with fast delivery and competitive pricing. This article will guide you through our meticulous manufacturing process, from material preparation to packaging and shipping.

The Manufacturing Process is

للتأكد من أنه يمكنك العثور بسرعة على المعلومات التي تحتاجها, لقد قمنا بإعداد دليل المحتوى. عندما تنقر عليه, سيتم نقلك إلى القسم المناسب.

Quality is the cornerstone of our manufacturing process. We believe that maintaining high-quality standards is essential to delivering products that meet our clients’ expectations and stand the test of time. Our commitment to quality is evident in every step of our manufacturing process, from selecting high-quality aluminum sheets to conducting thorough quality control checks on the finished panels.

The first step in our manufacturing process involves the selection of high-quality aluminum sheets. These sheets are then cut to the required size, ensuring precision and consistency across all our products.

Once the aluminum sheets are prepared, they undergo a grinding process. This process involves two stages: طحن الخام والطحن الناعم. Rough grinding removes the oxide layer on the aluminum sheet surface, while fine grinding smooths the surface and prepares it for further processing.

After grinding, the aluminum sheets are bent into the desired shape using a bending machine. This process is carefully controlled to ensure the accuracy of the shape and size. Our advanced bending techniques allow us to create a wide range of shapes and designs, catering to various architectural styles.

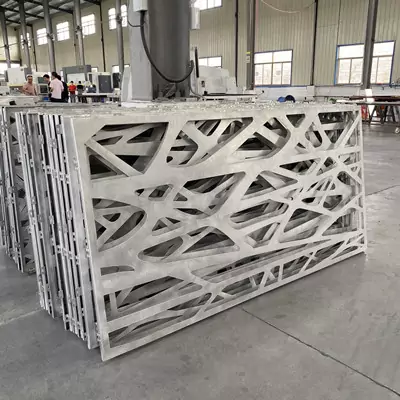

The next step in the process is perforation and engraving. We use a CNC turret punch to perforate the aluminum sheets according to the design. The CNC turret punch can perform various functions such as punching, stretching, and forming. It can also install dozens of sets of molds, rotating to locate the selected mold to the striking position. This advanced technology allows us to create intricate designs with high precision.

After perforation and engraving, the aluminum sheets undergo a powder coating process. This process involves several stages, including pre-treatment, primer application, topcoat coating, finishing paint application, and curing treatment. Each stage plays a crucial role in enhancing the durability, color uniformity, and anti-aging ability of the aluminum panels. Our powder coating process ensures a vibrant and long-lasting finish.

Once the aluminum wall panels are finished, they undergo a thorough quality control check. Our team inspects the panels for the correct size, شكل, لون, and finish, ensuring that each product meets our high-quality standards.

Finally, the finished aluminum wall panels are packaged for shipping. We take great care in packing our products to prevent damage during transportation. Our efficient logistics ensure fast delivery, allowing our clients to meet their project timelines.

Choosing Alumideas’ aluminum wall panels means investing in quality, design, والاستدامة. Our panels are not only aesthetically pleasing but also durable and environmentally friendly. They are suitable for a wide range of applications, from residential projects to commercial buildings. With Alumideas, you can expect products that combine innovation, وظائف, and style.

The thickness of the aluminum sheets used in the manufacturing process at Alumideas varies depending on the specific requirements of the project. لكن, we typically use sheets that are between 1.5mm and 3mm thick. This ensures optimal strength and durability while maintaining a lightweight profile.

The CNC turret punch used at Alumideas is capable of creating a wide range of designs. This includes simple perforations, intricate patterns, and complex forms. The versatility of the CNC turret punch allows us to cater to a variety of architectural styles and client preferences.

The powder coating on our aluminum panels is highly durable. It provides a protective layer that is resistant to weathering, تآكل, والأشعة فوق البنفسجية. This ensures that the panels maintain their vibrant color and glossy finish for many years, even when exposed to harsh environmental conditions.

في ألوميدياس, we perform a comprehensive quality control check on our finished panels. This includes checking the size, شكل, لون, and finish of the panels. We also inspect the panels for any defects or inconsistencies in the material or the coating. Our stringent quality control process ensures that every panel we produce meets our high standards of quality and durability.

To prevent damage to the panels during shipping, we carefully package each panel in protective materials. This includes using foam or bubble wrap to cushion the panels and prevent scratches or dents. We also use sturdy boxes or crates to protect the panels during transit. Our logistics team works closely with our shipping partners to ensure that the panels are handled with care and delivered in perfect condition.

ختاماً, the manufacturing process of aluminum wall panels at Alumideas is a meticulous process that prioritizes quality at every step. From material preparation to packaging and shipping, we ensure that our products meet the highest standards of quality and design.

Whether you’re an architect, a designer, a construction company, or a building owner, ألوميدياس’ aluminum wall panels are the perfect choice for your project. For more information about our products and services, لو سمحت اتصل بنا.

Alumideas شركة متخصصة في تصنيع ألواح الجدران المصنوعة من الألومنيوم في الصين. نحن نقدم حلاً شاملاً لمشاريع الكسوة الزخرفية الداخلية والخارجية الخاصة بك. طلب اقتباس الآن!

سوف نتصل بك في الداخل 1 يوم عمل, يرجى الانتباه إلى البريد الإلكتروني مع اللاحقة "@alumideas.com".

يساعدنا تبادل المعلومات السريعة على خدمتك بشكل أفضل

احصل على عرض أسعار فوري من مستشارينا المحترفين.

سوف نتصل بك في الداخل 1 يوم عمل, يرجى الانتباه إلى البريد الإلكتروني مع اللاحقة "@alumideas.com".