With over a decade of experience, Alumideas is a trusted and reliable company in the manufacturing of aluminum panels for walls and the resolution of engineering challenges.

Tiwhikete

ISO 9001:2015 | SGS tiwhikete | He mea nui ki nga Tirotiro Kounga

Aluminum wall panels are an excellent alternative to traditional cladding options such as wood or windshields. Want to know how aluminum siding can help with your building exterior projects? Check this blog: All You Want To Know About Aluminum Wall Panels.

Whakaritea ki etahi atu taonga i runga i nga pakitara o te arai, Ko te kaha o te konumohe me te mau tonu te whakarite i nga mea tino pai mo nga kaupapa hanga, A ko tona Maama e hangai ana he hau. Ka tukuna e Alumadeas nga momo mutunga katoa penei i te whakapaipai whakapaipai me te rakau rakau pumau, e taapiri ana i tetahi pa maori ki tetahi kaupapa hoahoatanga.

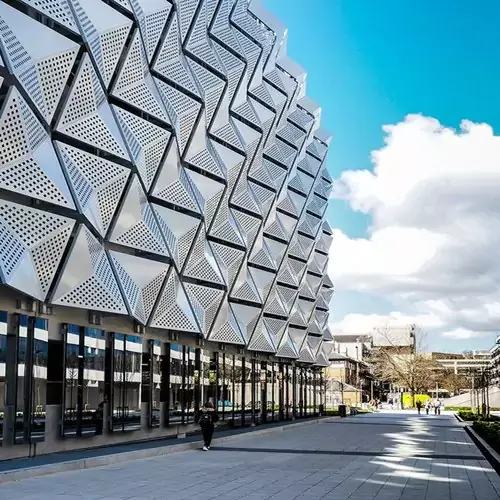

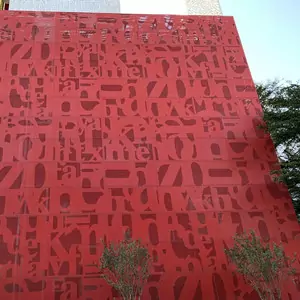

Library decoration

Art park

Gym exterio decorative

Shopping malls

Feature | Specification |

Origin | Made in China |

Brand | Alumida |

Certified By | ISO9000 International Standards |

Kupu | 80 sq.m |

Price | USD30-USD100/Sq.m |

Te takai | Securely packed with plywood & metal casing, added protection with film and bubble wrap |

Estimated Delivery | Within 15 ki 30 nga ra |

Te kaha o te whakaputa | Up to 30,000 sq.m monthly |

Material Composition | Premium Aluminum Alloy |

Recommend Size | 1000mm x 2000mm |

Thickness Options | Between 1.5mm to 10mm |

Surface Options | Choice of Powder Coating or Pvdf Paint |

Available Colors | Versatile palette including all RAL colors, rakau, stone, and metallic finishes |

Ideal For | Windows, Fences, Nga Wharangi Hangahanga, Curtain Walls, Decorative Screens, me etahi atu |

Maximum Size | Up to 1500mm x 5000mm |

Manufacturing Techniques | Advanced methods including CNC Cutting, Te piko, Tapahi Taiaho, Carving, and Engraving |

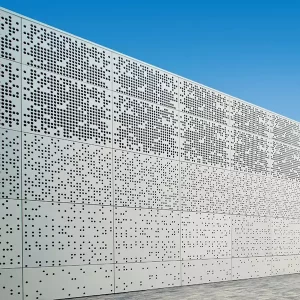

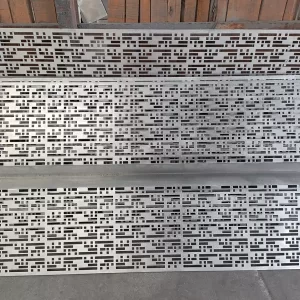

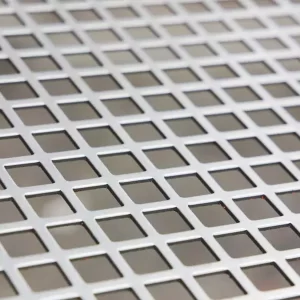

There are many materials of punching plate, mostly stainless steel plate, aluminum plate, iron plate, copper plate, me etahi atu. At present, most of the punched plates seen on the market are punched aluminum plates. The punched aluminum plate is light in material, good in chemical stability, beautiful in appearance, elegant in color, strong in three-dimensional effect, good in decoration, and easy to assemble.

For more details on the production process of punching aluminum wall panels, please kindly check this blog: Turret Punch For Aluminum Perforated Panel

The hole types of the punching plate are rectangular hole, square hole, diamond hole, round hole, long round hole, hexagonal hole, cross hole, triangular hole, long waist hole, plum blossom hole, fish scale hole, pattern hole, eight-character net, Herringbone holes, pentagram holes, irregular holes, drum holes, special-shaped holes, grid holes, etc.

The punched aluminum panels will produce rich light and shadow changes under the illumination of sunlight or light. This effect will give the building a unique and dynamic visual effect. This light and shadow effect makes the relationship between the main body of the building and the outer skin more holistic and layered. The size of the hole the change of the aperture and the perforation rate will also produce different effects of light and shadow changes.

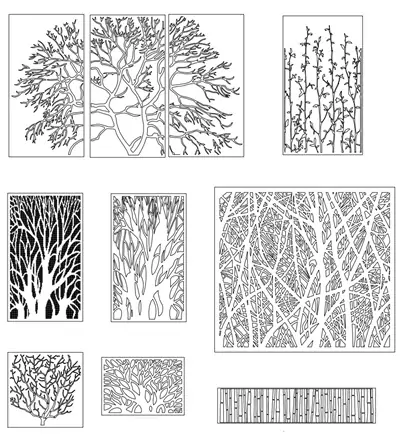

As a kind of engraving artwork, the engraved aluminum wall panels adopt advanced CNC laser engraving equipment to engrave the aluminum plate according to the design pattern, the process accuracy is high, and the surface is not damaged. The equipment is suitable for all kinds of complex pattern engraving such as high-precision, complex graphics, large-scale graphics, special-shaped graphics, and curve graphics.

The aluminum plate can be processed into a non-standard carved hollow aluminum veneer of various specifications and shapes. According to the designer’s requirements, the engraving panels can be equipped with many kinds of decorative patterns, which are suitable for ceilings, curtain walls, aluminum wall panels interior designs, and pillars, and can meet customers’ fashion and individual pursuit of aluminum panel decoration.

The perforated aluminum plate has the characteristics of light weight, corrosion resistance and high temperature, fire and moisture resistance, and good chemical stability. Easy installation and maintenance, and good decorative effect make perforated panels very versatile in usage.

For more details of the aluminum wall panel engraving production process, please kindly check this blog: Aluminum Engraving Panel Production

The important features of hyperbolic aluminum wall panels, such as spherical surface and vase shape, are hyperbolic aluminum solid panels composed of multiple textures. There are two important processing techniques that are difficult, each of which needs to be divided and calculated once, cut, and once again lead the welding of aluminum panels to the consideration of burning aluminum sheet.

For more production details of aluminum hyperboloid panels, please kindly check this blog: How Does Arc Rolling Aluminum Cladding Panel Come Out?

The hyperbolic aluminum panel is different from the ordinary shape of the aluminum panel The manufacturing process of the hyperbolic aluminum panel is complicated, difficult, and requires high mechanical and technical personnel. The double-curved aluminum panels curtain wall can be made into different shapes and different individual construction styles to meet different construction requirements and is often used as the outer wall cladding of local landmark buildings

The overall aesthetic appeal of a building is largely determined by the exterior styling of the building. The use of 3D aluminum curtain walls can not only reduce the impact due to environmental problems, but also enhance the attractiveness of the building.

The designer’s design concept can be well expressed through the 3D aluminum curtain wall, and the advantages of environmentally friendly materials and convenient installation are also in line with the development concept of the current era.

Ko nga panui pakitara whakarakei tetahi o nga hoahoa papanga pakitara tino rongonui i enei ra. E kore e taea e te punaha whaanui te kitea te toenga tika i waenga i te ra me te whakamarumaru ma te whakatika i nga whakamarumaru i nga ra paki.

I taua wa ano, ka taea hoki te whakamarumaru kaha ki te kino o te rangi ina he kapua. Ka awhina i te whakamarumaru kia maroke, tiaki i te makuku, me te pupuri i te mahana i roto i te whare.

Alumideas is an aluminum decorative wall panel supplier in China with 12 years of manufacturing experience, here’s our full production process for aluminum wall cladding panels:

1. Pretreatment

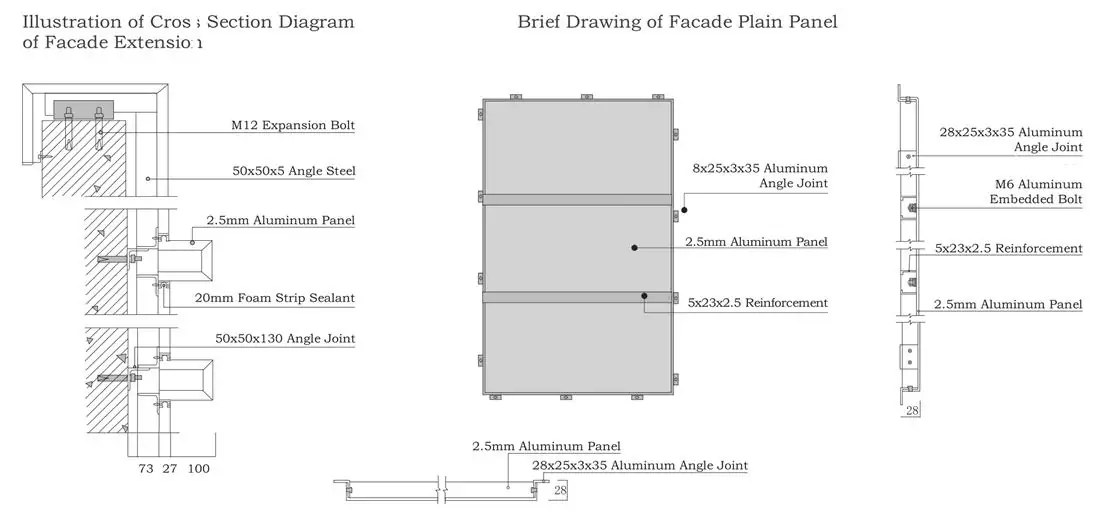

Before spraying, the surface of the workpiece should be degreased, decon-soiled, and chemically treated to produce the chrome-plated film, which will increase the oxidation resistance of the metal and also the adhesion between the coating and metal surface, and thus prolong the service life of the coating. For parts that are not allowed to be sprayed, protective film or adhesive tape should be pasted on the corresponding parts after pretreatment and should be torn off in time after spraying.

2. Hook

Aluminum of different shapes is hung on the production line with corresponding hooks. The maximum length, width, and height of aluminum that can be contained in the oven is 6m, 1.1m, and 2m respectively, therefore, aluminum panels should be hung steadily at appropriate angles. Before painting primer, observe whether there is dirt on the surface, if yes, sand it with sandpaper, and blow it off with an airbrush.

3. Primer coating

Its role is to improve the permeability resistance of the base material, stabilize the metal surface, enhance the adhesion between the second coating and the metal surface, and ensure the color uniformity of the surface.

4. Top coating

This key layer is to provide decorative colors, ensure that the appearance of aluminum material meets the design requirements, protect the surface from environmental corrosion, and prevent ultraviolet penetration. It greatly enhances the anti-aging ability of the product. The top coat is the thickest paint used in surface coating.

5. Varnish

The main purpose of varnish is to enhance the anti-corrosion ability of the paint layer, protect the surface finish, and increase the metallic luster of the finish color, making the appearance more bright and dazzling.

6. Curing treatment

After three times of spraying, the aluminum plate is put into the curing furnace for processing for about 20 minutes. The curing temperature is generally between 180℃ and 250℃.

7. Quality inspection

Quality inspection is done according to specific standards. Observe whether there are scratches or spots on the surface, and check the product color with a color meter and paint thickness with a film measuring instrument.

8. Lower the hook

When lowering the hook, be careful to remove the sprayed aluminum from the hook. When placed inside the truck, the painted surface should face the painted surface to prevent scratching the coating.

9. Te takai

Packaging personnel will transport the painted aluminum plate to the designated position, wrap them with packaging film, and fix a piece of paper at each corner with adhesive tape to prevent abrasion. The painted surface of one aluminum plate faces that of the other aluminum plate, with the front facing forward to prevent the paint surface from being scratched.

8. Lower the hook

When lowering the hook, be careful to remove the sprayed aluminum from the hook. When placed inside the truck, the painted surface should face the painted surface to prevent scratching the coating.

9. Te takai

Packaging personnel will transport the painted aluminum plate to the designated position, wrap them with packaging film, and fix a piece of paper at each corner with adhesive tape to prevent abrasion. The painted surface of one aluminum plate faces that of the other aluminum plate, with the front-facing forward to prevent the paint surface from being scratched.

Hei whakaora wa koe, kua whakaritea hoki e matou nga putanga PDF o nga putumōhio hua katoa, waiho noa to imeera ka whiwhi tonu koe i te hononga tango.

Te kaha:

Rauemi:

Te matotoru:

Rahi:

Matamata:

Whakaaetanga:

1,200,000 mita tapawha/Tau

1100H24 / 1060H24 / 3003H24 / 5005H24

1.0 ~ 5.0mm kei te waatea katoa

600*600 / 600*1200mm / 1220*2440mm(rahi paerewa)

/ rahi whakaritea

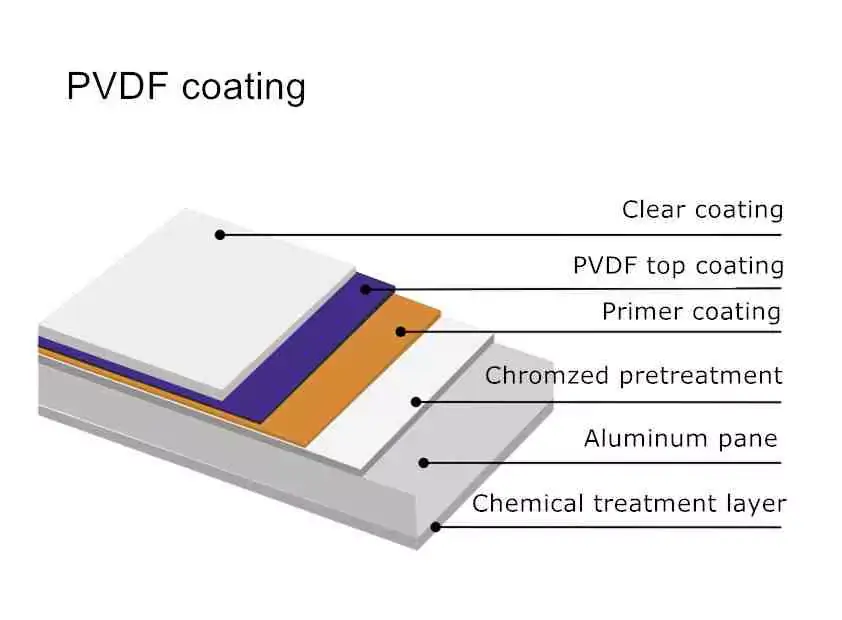

Roera paninga / PVDF paninga / Te paninga paura

Tikanga, Ka taea e Alumideas te pupuri i te machining thickness tolerance o ±0.2mm me te roa me te whanui whanui o te ±2mm.

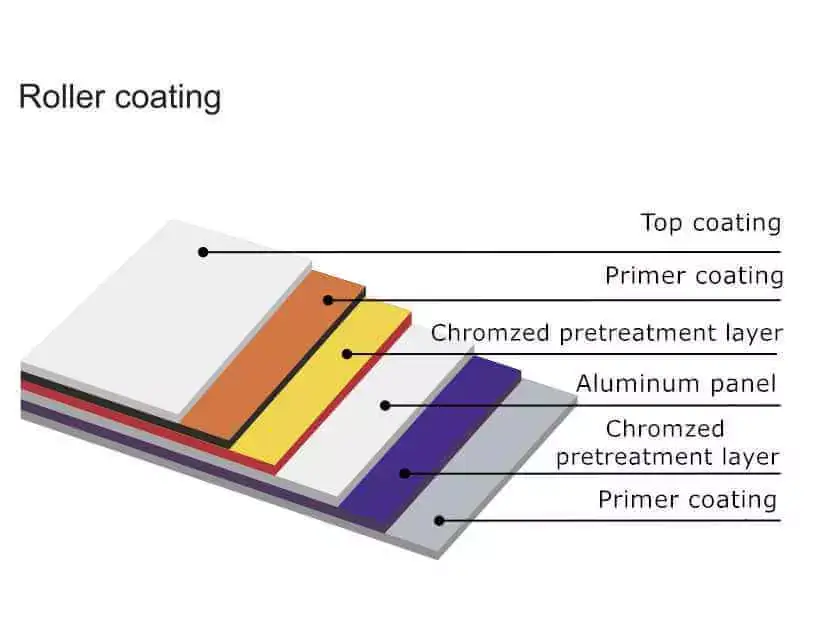

Roller-coated aluminum panel is firstly coated with fluorocarbon coating by a roller coating process, and then processed into a certain structure by sheet metal processing technology. Its color is very realistic and stable with a long service life.

Roll-coated aluminum panels can effectively control the precision and flatness, and fundamentally eliminate the depressions and wrinkles on the surface of aluminum panel ceilings caused by traditional spraying processes. The aluminum panel has a uniform color and a high finish.

The film thickness is only 0.4mm, which is 0.1mm thinner than that of the composite board. Compared with composite panels, roll-coated aluminum panels are not easy to color. The composite board is soft, clean, and not easy to scratch, but the price is high.

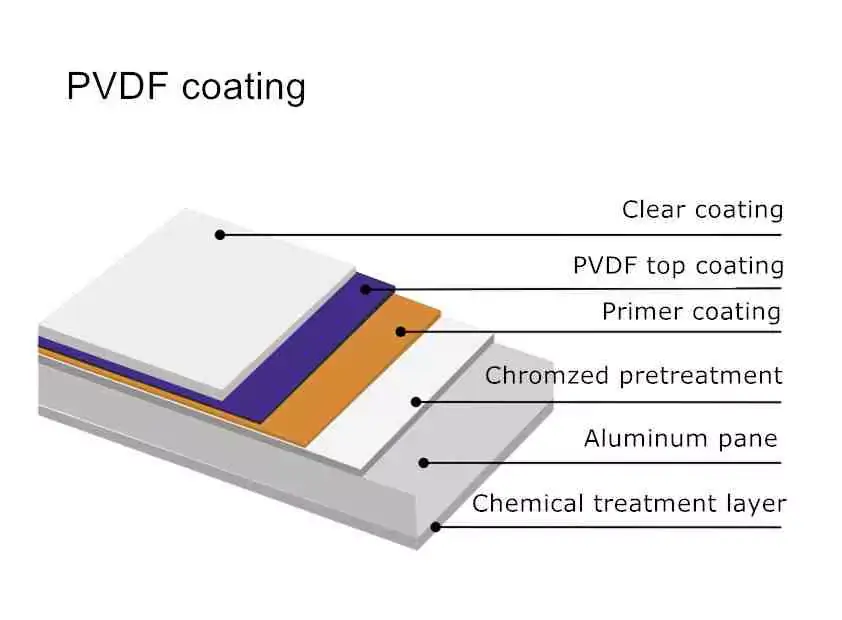

Primer coating:

Its role is to improve the permeability resistance of the base material, stabilize the metal surface, enhance the adhesion between the second coating and the metal surface, and ensure the color uniformity of the surface. The thickness of the primer coating layer is generally 5-10 microns.

Top coating:

This key layer is to provide decorative colors, ensure that the appearance of aluminum material meets the design requirements, protect the surface from environmental corrosion, and prevent ultraviolet penetration. It greatly enhances the anti-aging ability of the product. The top coat is the thickest paint used in surface coating. The paint layer thickness is generally 23-30 microns.

Clear coating:

The main purpose of varnish is to enhance the anti-corrosion ability of the paint layer, protect the surface finish, and increase the metallic luster of the finish color, making the appearance more bright and dazzling. The coating thickness is 5-10 microns commonly. The total thickness of the three coating layers(primer coating, top coating, and clear coating) is generally 40-60 microns and can be thickened if needed.

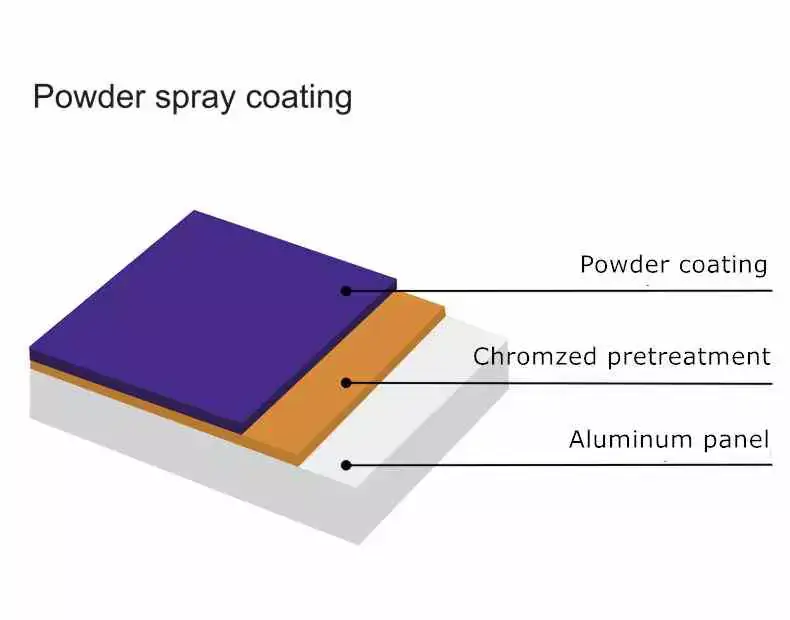

Adopting the principle of electrostatic spraying, the dry powder is stuck to the metal aluminum profile. After more than 200℃ baking, the powder solidifies into a strong and bright coating about 60 microns thick.

After powder coating, the panel’s surface will be smooth and the color will be uniform. The powder-coated panel has strong resistance to acid, alkali, ariā, and wear, and can withstand intense ultraviolet radiation and acid rain for a long time without fading. Normally, powder-coated products have a service life of up to 30 tau. Its coating guarantees no fading, no discoloration, or cracking within 5-10 tau.

For more details for the powder spray coating production process, please kindly check this blog: Aluminum Panel Powder Coating Process

1. Whakamahia nga taputapu waka poutū penei i nga etaka ki te kawe i nga papa konumohe me nga taonga ki ia kohinga hanga.

2. Ko te pereti konumohe katoa e hono ana me te arai i roto i te taha o te taha waehere kokonga konumohe (ārare) a ka mau tonu i runga i te hiku.

3. Tikanga whakatika: Mena he mea hanga-i roto i te riipene, Whakapaihia i te waahi e tika ana i runga i te Keel, katahi ka rukuhia ki te upoko papatahi (upoko upoko) konumohe rivet; Ki te mea he riipene moana, Whakamahia nga kowiri tira pereti (e kiia ana hoki ko te piripiri piripiri, ko nga piripiri phoenix ranei) ki te tirotiro tika ki te matau i roto i nga rua o te waehere kokonga konumohe hei whakatika i te pereti konumohe, Engari kia tupato ki te whakahaere i te mana o te brill bit.

4. I te wa o te whakawa, Kia whai whakaaro ki te tika o te whakaurunga, ka whakatika i te pereti konumohe i mua i te piri.

5. I te whakauru, the aluminum plate should be installed on the wall according to its serial number.

6. The installation of aluminum plates always starts from the front, He rohe nui, me nga waahanga kokonga, ka whakauruhia mai i runga ki raro.

7. Ko te hononga i waenga i te pereti konumohe ka tutuki i nga hiahia o nga pikitia, Me kaha, kia pumau, me whakauru nga paanui.

Whakapotohia to huringa whanaketanga hua ma nga wiki (me etahi marama) and produce aluminum panesl sample and finish qualification tests within days. Some aluminum panels samples can be shipped within 3 nga ra.

Kei roto i ia korero te utu mo te wa tuturu me te tātari hoahoa. Ka arotakehia e matou to CAD 3D me te awhina ki te tautuhi i nga ahuatanga ka raru pea i te wa o te mahi whakangao., pnei i te whakakopa maha o nga pereti ahua motuhake me te whakairo tino tika.I tua atu, Ka taea e ta maatau roopu miihini tono mohio te korero mo to hoahoa ahurei, arotake i nga utu hokohoko, me te awhina i a koe ki te arotau i nga tuhi pepa konumohe me te whakarereke i nga hoahoa ma o maatau ratonga hoahoa korero.

Kua oti ia matou te raina taputapu rehu aunoa, oumu whakahaere pāmahana, Pūnaha wera LPG me te hangarau whakamaoritanga Tiamana. Ko te mata he mea hanga ki te paninga PVDF teitei mai i te PPG, DNT, AKZO, NIPPON me etahi atu kaihanga whakakikorua PVDF rongonui o te ao, me te whānuitanga o nga tae ka taea te whakarite i tetahi tae me to tauira tae

Kua mutu a Alumideas 60+ kaupapa o tawahi i roto i neke atu i te 30 whenua mo neke atu i te 10 tau. He mohio ki te hoahoa whakakikorua taiepa konumohe me nga tikanga whakaurunga i nga whenua rereke me te kaha ki te tuku tohutohu ngaio, hei whakatairanga i nga kaupapa miihini a nga kaihoko

Tikina he korero tere mai i a maatau kaitohutohu ngaio.

Ka whakapā atu matou ki a koe i roto 1 ra mahi, kia aro mai ki te imeera me te kumara “@alumideas.com”.

Ko te Whakawhitinga Korero Tere ka awhina i a maatau ki te mahi pai atu ki a koe