On May 30th, Miss Vivian, sent us an inquiry about aluminum punched panels for the decoration of backdrop. After several days of communication, we made consensus and sent two sets of samples with two different colors to Malaysia for quality check and installation.

As the building is not finished, the actual size should be confirmed before moving forward, which took almost a month.

On September 13th, production drawing was confirmed. Mass production began. The products were loaded on October 5th.

Overall Introduction

Location: Malaysia

Area: roughly 173 mita tapawha.

Thickness of the panels: 2.5mm

Te maimoatanga mata: Te rehu PVDF

Tae: RAL 7040

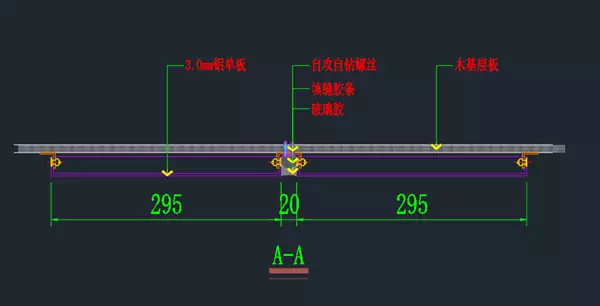

Installation Method: seam installation

Corner bracket: countersink

Rib reinforcement: Not required

Details

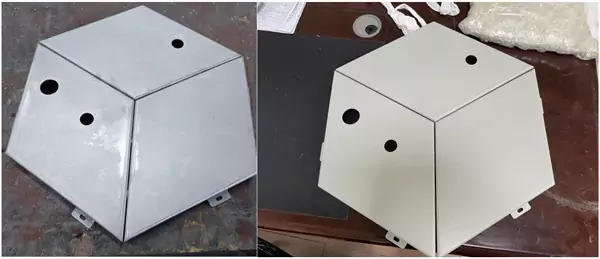

Sample Confirmation

Installation Method Confirmation

Difficulty of the Project

Solution 1: Black glue: i muri i te whakaurunga, the overall effect is not satisfactory as shown below. This solution is not selected.

Solution 2: aluminum trim: too many angles among the panels, will be too difficult to cut and install onsite. Abandoned.

Final solution: using wood trim to caulk. This solution is suggested by Vivian and the effect is satisfactory.

Why seam installation instead of seamless splicing installation?

As there are lights behind the aluminum punched panels, if using seamless splicing installation, the maintenance of lamps will be inconvenient and also cost too much labor and money. At the same time, as the wall of backdrop is not finished, considering that there will be tolerance, seamless installation will not be suitable.

However, if use seam installation, the problems above will not be problems.

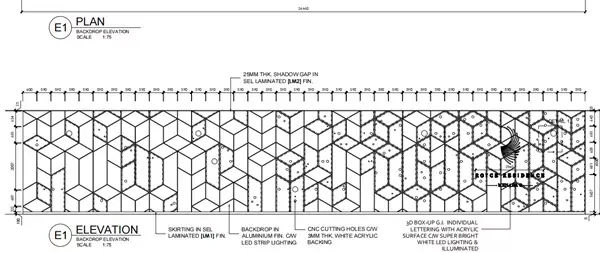

Drawing Revision

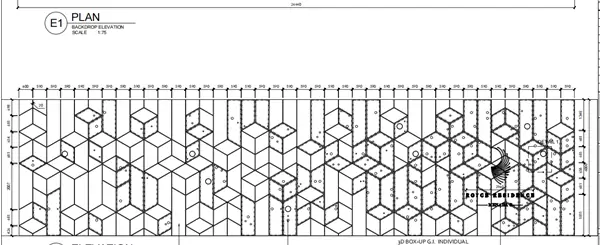

Original Drawing:

Rahi:24440*6000mm

Revised Drawing:

Rahi:24440*4500mm

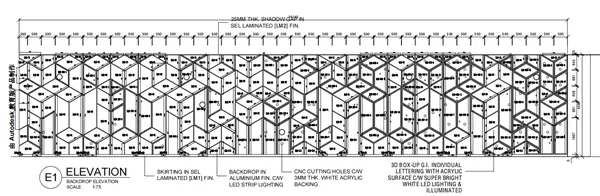

Production Drawing Confirmation

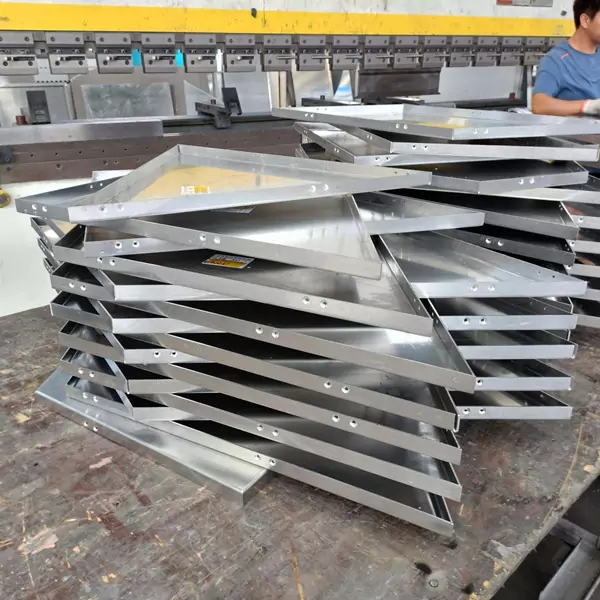

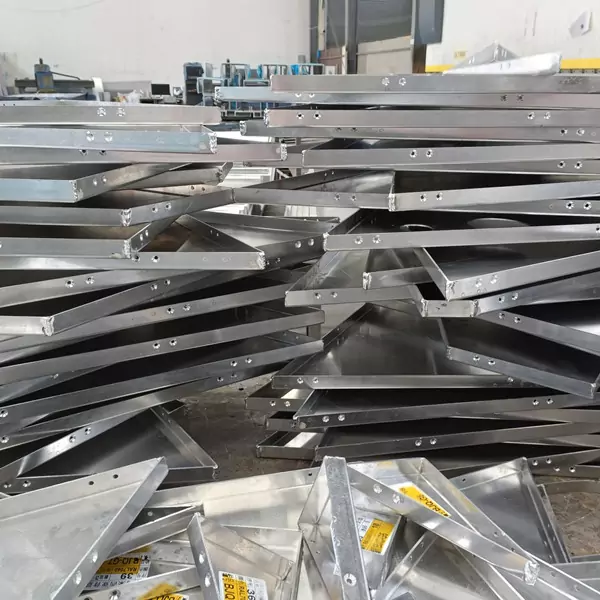

Mass Production

Te whiu:

Bending:

Wehenga:

Grinding:

Corner Bracket:

Polishing:

PVDF Spraying:

Delivery

At Alumideas , our products are widely used for exterior and interior in architecture and building, shopping mall, hōhipera, metro station, railway station etc. For multifunctional advantage like ventilation, decoration, partition, excellent in lights transmission and so on.

If any requirement for Aluminum decorative panel please contact us ! We will offer the best quote and service !