Polyester paint process of aluminum veneer panel

Polyester paint is one of the common surface treatments for aluminum plate. This article mainly introduces the polyester paint in the spraying process of aluminum veneer panel.

learning from experience

Polyester paint is one of the common surface treatments for aluminum plate. This article mainly introduces the polyester paint in the spraying process of aluminum veneer panel.

In order to improve the decorative effect of the exterior wall of aluminum plate, enhance the corrosion resistance and extend the service life, aluminum plate is generally treated, and aluminum surface treatment has become an essential important production link in the process of aluminum processing. Fluorocarbon spraying is one of the important aluminum surface treatment methods

Spray coating is a very important process in the manufacturing of aluminum veneer panel. This article will briefly introduce the powder spraying of aluminum veneer, including some basic information of powder coating, the process, features, the standard of film thickness, etc., so that we can better choose the most suitable products in future projects.

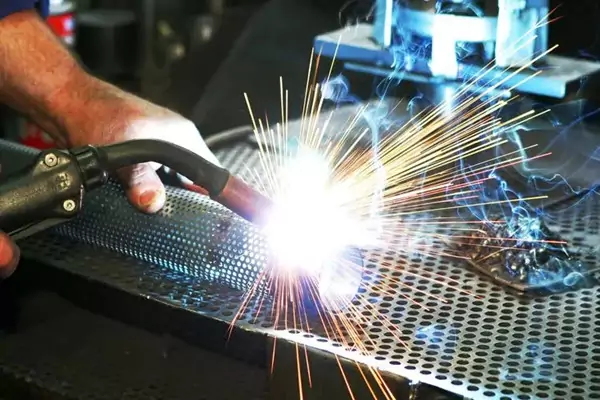

This article is to introduce welding process in aluminum panel industry. Welding of aluminum veneer panel is an important process. If it is not welded, it will lead to deformation of aluminum veneer panel during logistics and transportation. So welding has a fixed effect for keep the aluminum veneer panel’s shape remaining unchanged.

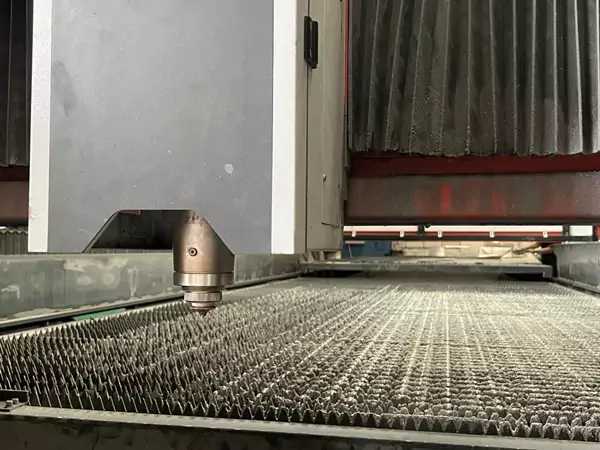

In this article, we will introduce laser cutting in the aluminum panel engraving process.

As we all know, perforated panels are very popular products in the field of aluminum panel. This article is to briefly introduce some useful information about the engraving machine which is a vital machine when producing perforated panels.

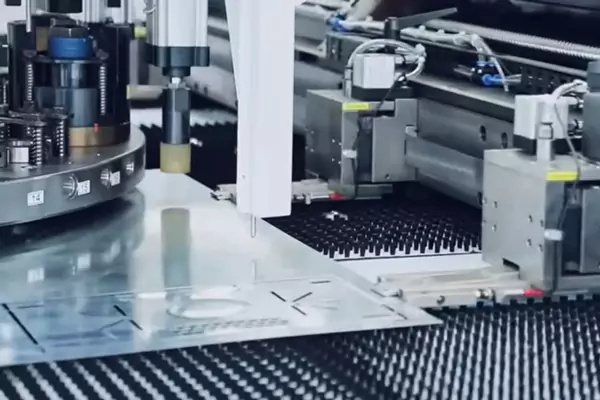

This article is to introduce aluminum panel punching, which is also called CNC turret punch in aluminum panel industry.

This article mainly introduces the grinding process in the aluminum veneer panel production.

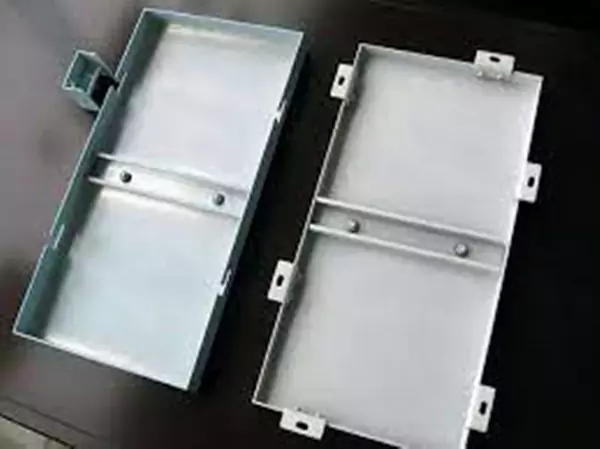

Generally, aluminum panel is composed of panel, reinforcing ribs and aluminum corner codes. This article will introduce the reinforcing ribs and corner codes which are general accessories required when installing aluminum panels.

Bending is an indispensable step in the production process. Its main functions are to enhance the rigidity of the aluminum plate, increase the practicability and aesthetics, and at the same time facilitate installation and splicing. The following will introduce the bending principle and process of aluminum plate in detail.

Quick Info Exchange Helps Us Serve You Better

Get an instant quote from our professional consultants.

We will contact you within 1 working day, please pay attention to the email with the suffix “@alumideas.com”.