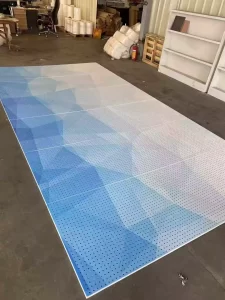

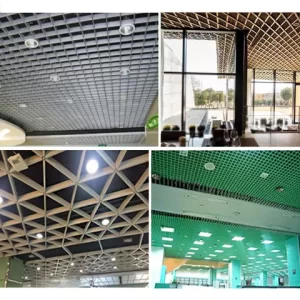

Nowadays, panui konumohe, whai wāhi aluminum veneers, aluminum honeycomb panels, aluminum composite panels a aluminum ceilings, are increasingly applied in the construction industry, no matter in civil or commercial buildings.

Section of content

It is not easy to introduce all aspects of these mechanical properties of tempers for aluminum panels, so we have prepared a lot of information on this page for you to delve into. To make sure you can find the information you want quickly, below content directory that will jump to the corresponding location when you click on it.

This article is to provide some useful information on the most common aluminum alloy used for aluminum panels on the angle of compare ten vital properties of these alloy.

The following are the definition of these ten properties.

- Modulus ngawari:An elastic modulus (also known as modulus of elasticity) is the unit of measurement of an object’s or substance’s resistance to being deformed elastically (i.e., non-permanently) when a stress is applied to it. The elastic modulus of an object is defined as the slope of its stress–strain curve in the elastic deformation region: A stiffer material will have a higher elastic modulus.

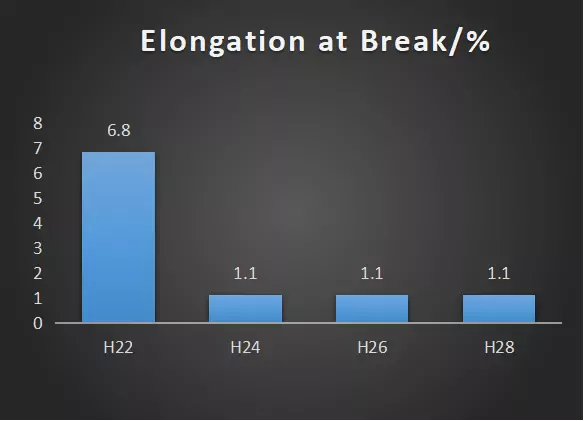

- Elongation at Break: Elongation at break is the measure of a materials ductility. This measurement shows how much a material can be stretched, as a percentage of its original dimensions, before it breaks. It indicates the ability of a material to undergo significant deformation before failure.

Materials with a higher elongation at break percentage have higher ductility.

- Fatigue Strength: Fatigue strength is the highest stress that a material can withstand for a given number of cycles without breaking.

- Poisson’s Ratio: In materials science and solid mechanics, Poisson’s ratio is a measure of the Poisson effect, the deformation (expansion or contraction) of a material in directions perpendicular to the specific direction of loading.

- Shear Modulus:The shear modulus is a measure of the ability of a material to resist transverse deformations and is a valid index of elastic behaviour only for small deformations, after which the material is able to return to its original configuration.

- Shear Strength:In engineering, shear strength is the strength of a material or component against the type of yield or structural failure when the material or component fails in shear. A shear load is a force that tends to produce a sliding failure on a material along a plane that is parallel to the direction of the force. When a paper is cut with scissors, the paper fails in shear.

- Tensile Strength: Ultimate(UTS):Ultimate tensile strength (UTS), often shortened to tensile strength (TS), ultimate strength, is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials the ultimate tensile strength is close to the yield point, whereas in ductile materials the ultimate tensile strength can be higher.

- Tensile Strength: Yield(Proof): Yield strength is the maximum stress a material can endure beyond which it begins to permanently deform, not able to return to its original dimensions.

- Thermal Conductivity:The thermal conductivity of a material is a measure of its ability to conduct heat.

- Thermal Expansion:Thermal expansion is the tendency of matter to change its shape, area, volume, and density in response to a change in temperature, usually not including phase transitions.

What is H state ?

H: Strain Hardened, (applied to wrought products only) used for products that have been strengthened by strain hardening, with or without subsequent heat treatment.

The H states are followed by two or three digits.

H1X Strain hardened only

H2X Strain hardened and partially annealed

H3X Strain hardened and stabilized by a low temperature heat treatment or by heating carried out during working

H4X Strain hardened and lacquered or painted. This assumes that thermal effects from the coating process affect the strain hardening; seldom encountered

The second digit corresponds to the final degree of strain hardening, which is characterized by a minimum tensile strength value.

HX2 Quarter hard, equivalent to strain hardening of about 12%

HX4 Half hard, equivalent to strain hardening of about 25%. This condition indicates an ultimate tensile strength (UTS) halfway between the annealed and hard temper conditions

HX6 Three-quarter hard, equivalent to strain hardening about 50%

HX8 Hard, equivalent to strain hardening about 75%

HX9 Designates tempers in which the UTS exceeds by at least 10 MPa the tensile strength of HX8 tempers

What’s the most widely used alloy tempers for panui konumohe?

They are 1060H24, 1100H14, 1100H24, 3003H14, 3003H24 and 5052H32.

What’s the difference?

See the below charts and analysis to learn about their difference.

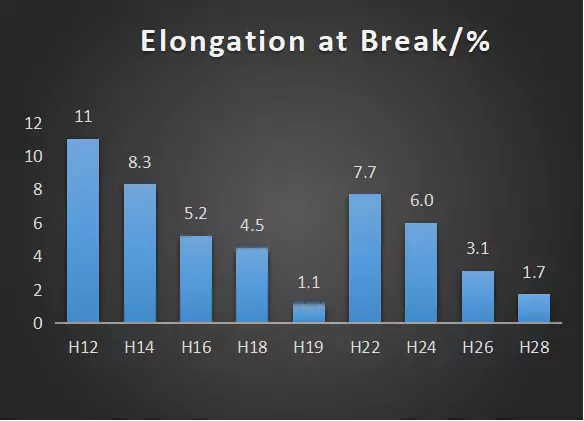

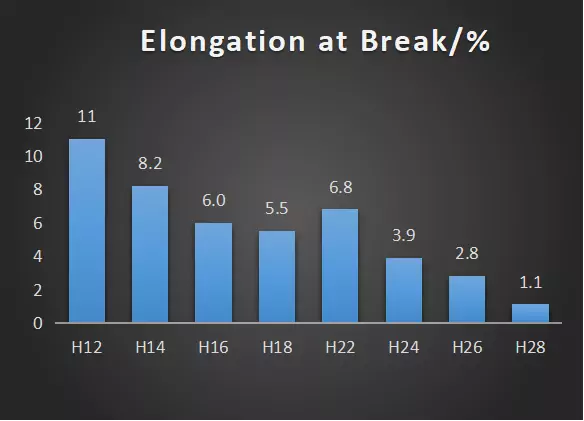

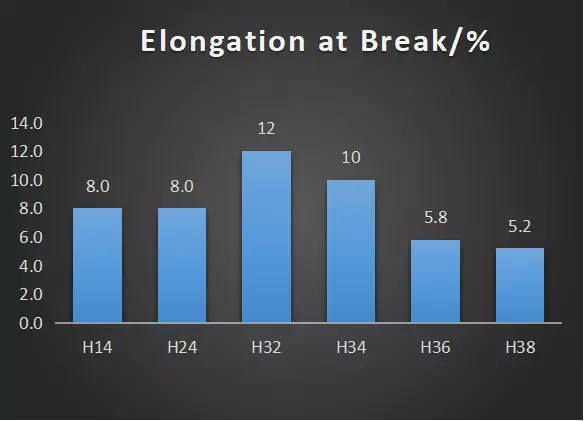

A.Elongation at Break

1060

3003

1100

5052

From the above four charts, we can learn that for Elongation at Break, the value for 1060H24, 1100H14, 1100H24, 3003H14, 3003H24 and 5052H32 is 1.1%, 8.2%, 3.9%, 8.3%, 6.0% a 12% respectively. 1060H24 is the lowest and 5052H32 is the highest, showing that in these six tempers, 5052H32 has a better performance in ductility while 1060H24 is not so good in ductility.

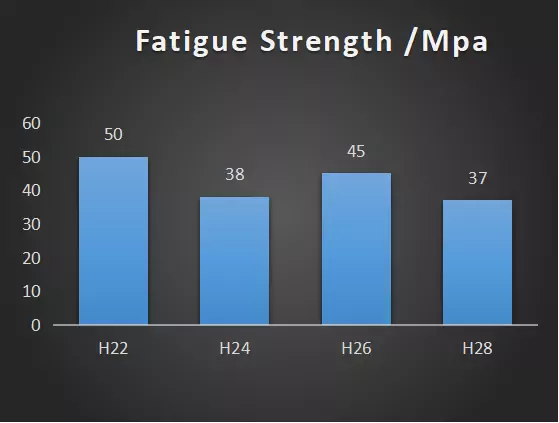

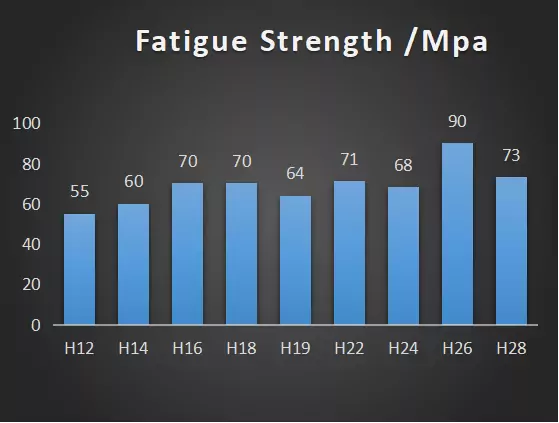

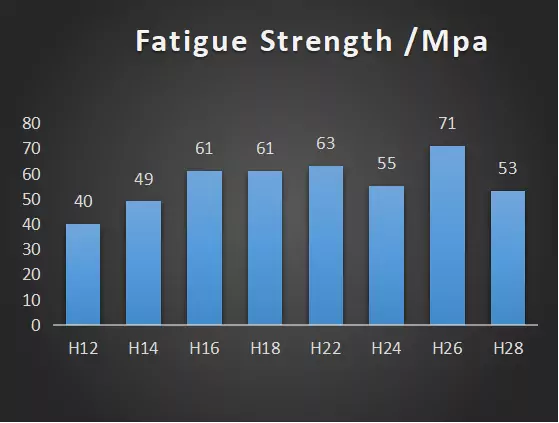

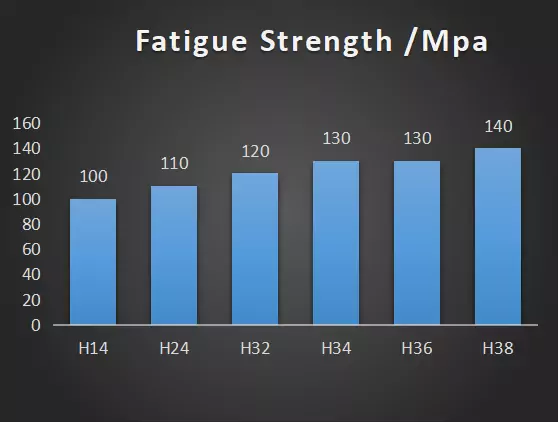

B.Fatigue Strength

1060

3003

1100

5052

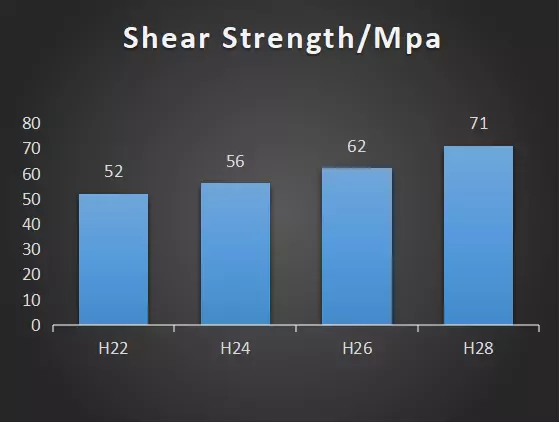

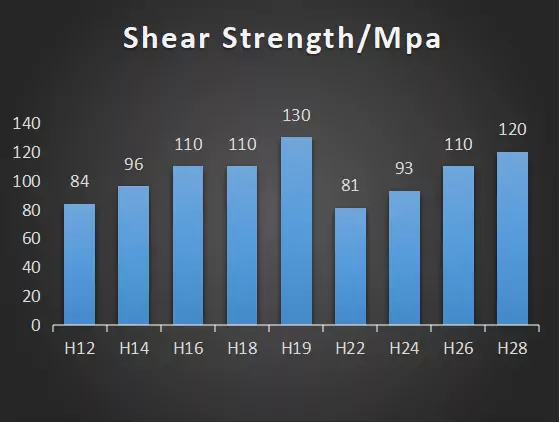

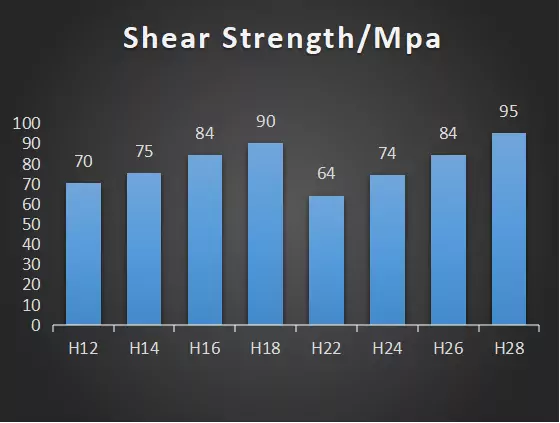

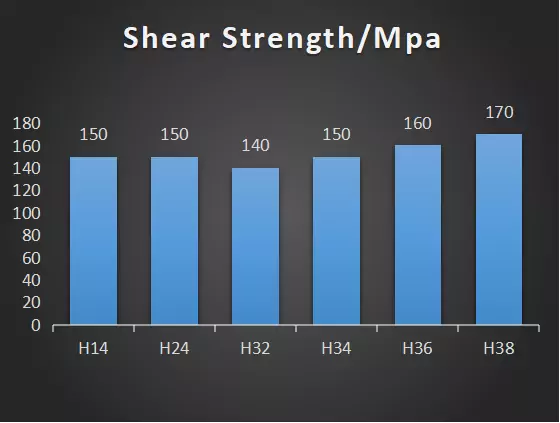

C.Shear Strength

1060

3003

1100

5052

From the above four charts, we can see that the value for Shear Strength for 1060H24, 1100H14, 1100H24, 3003H14, 3003H24 and 5052H32 is 56MPa, 75MPa, 74MPa, 96MPa, 93MPa, and 140MPa. Still, we can see that 1060H24 is the bottom and 5052H32 is the top, suggesting that 5052H32 will not fail in shear even all of the other five tempers fail. It is no wonder that 1060 scores the lowest as it contains more than 99.60% percent of aluminum which is seen as a easily-cut material.

An interesting phenomenon is that with the same alloy, the value for H14 is a little bit higher than that of H24. As stated at the very beginning, H1X is strain hardened only and H2X is strain hardened and partially annealed. No reira, we can conclude that annealing will have a negative effect on shear strength.

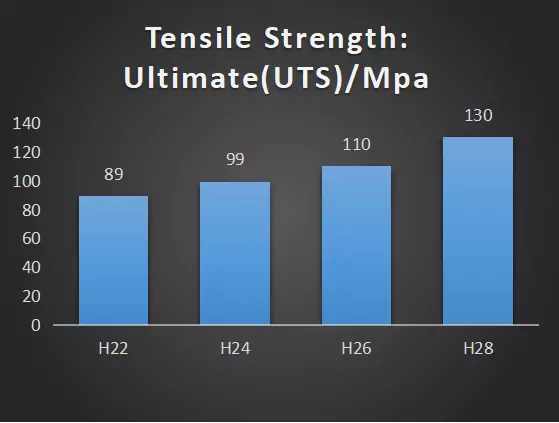

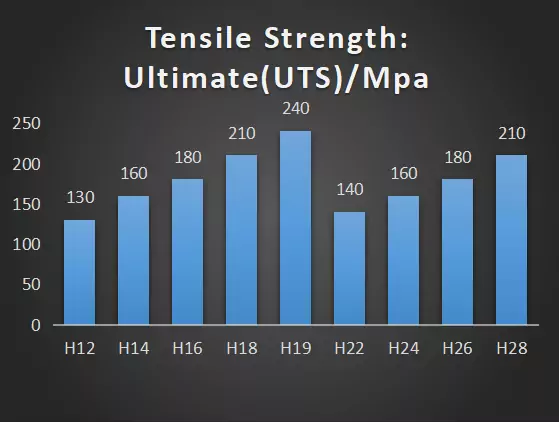

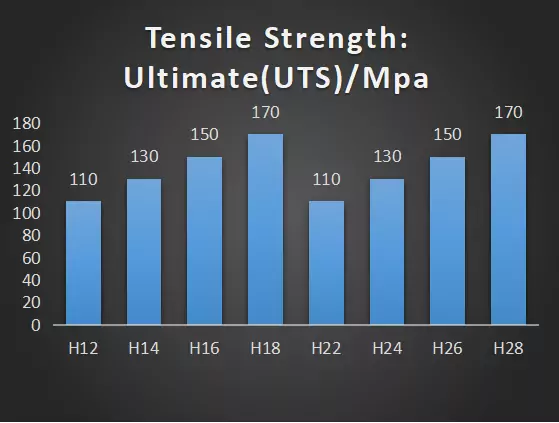

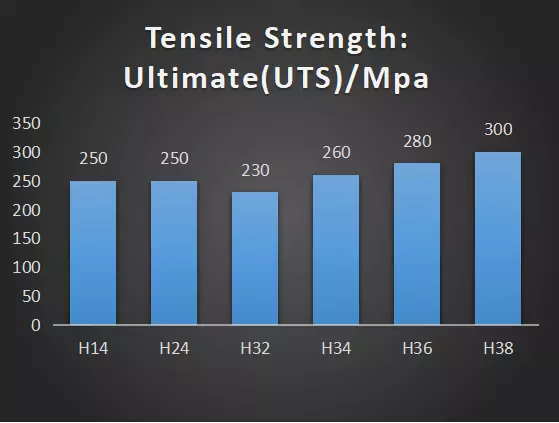

D.Tensile Strength: Ultimate(UTS)

1060

3003

1100

5052

The four charts tell that the UTS for 1060H24, 1100H14, 1100H24, 3003H14, 3003H24 and 5052H32 is 99MPa, 130MPa,130MPa, 160MPa, 160MPa and 230MPa respectively. As the volume of aluminum decreases, 1100 has a better performance than 1060 whatever the temper is, so as 3003 ki 1100 a 5052 ki 3003. 5052H32 is strong in strength, but the disadvantage is that when in production, its scrap rate is much higher than other tempers, increasing the cost. So it is often the case that we will use 3003 instead when the budget is tight.

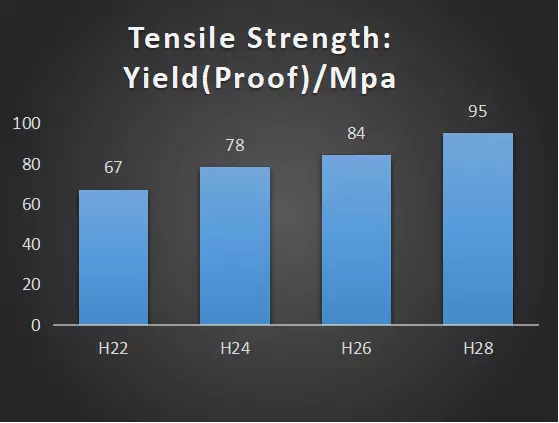

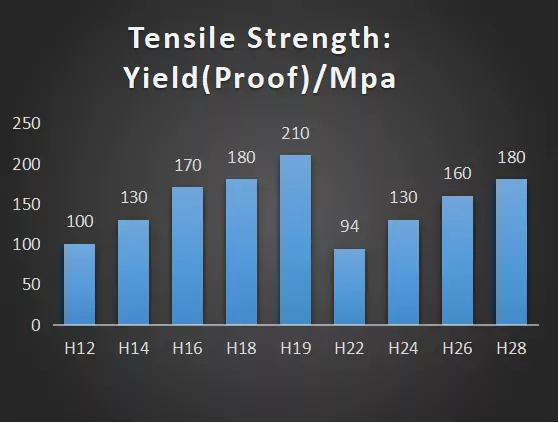

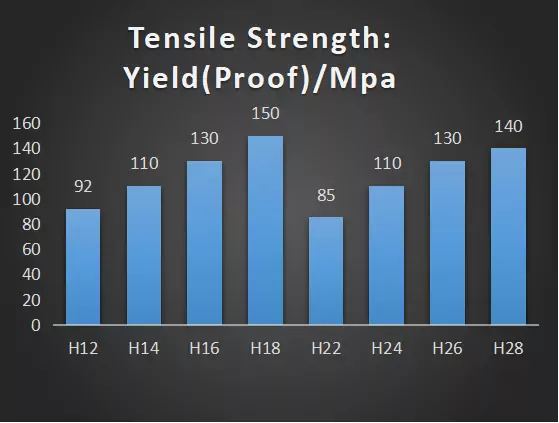

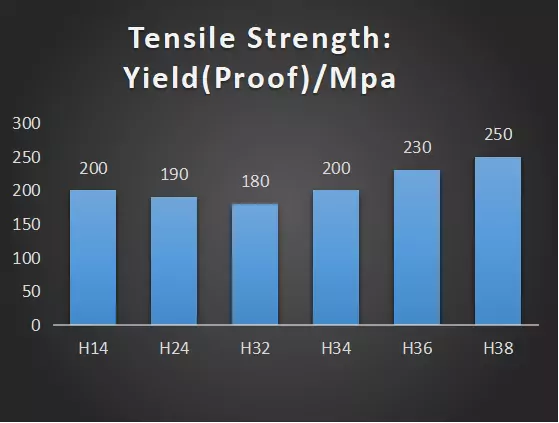

E.Tensile Strength: Yield(Proof)

1060

3003

1100

5052

We can see from the charts that the Tensile Strength: Yield(Proof) for 1060H24, 1100H14, 1100H24, 3003H14, 3003H24 and 5052H32 is 78MPa, 110MPa, 110MPa, 130MPa, 130MPa, and 180MPa respectively. It shows that 1060H24 material is the most easy permanent-deformed material, 1100 the second, 3003 rates after 1100, 5052 the most difficult.

As the value of some properties is the same with the same alloy, we make them into a chart and try to show their similarity and also difference.

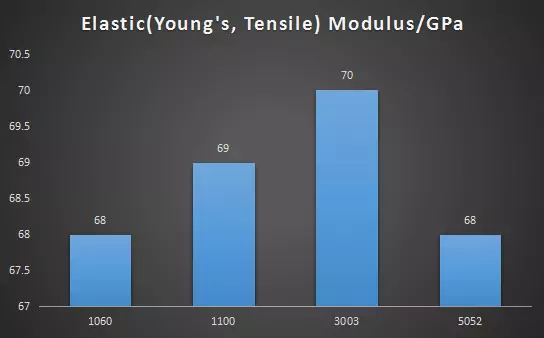

Elastic(Young's, Tensile) Modulus

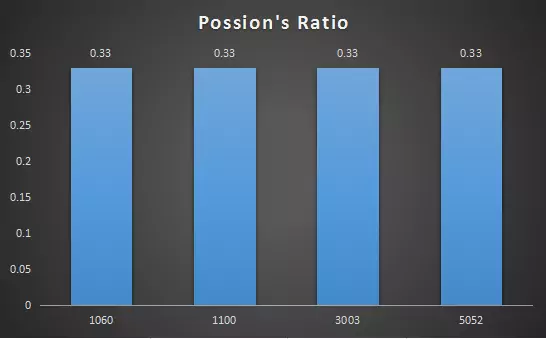

Possion's Ratio

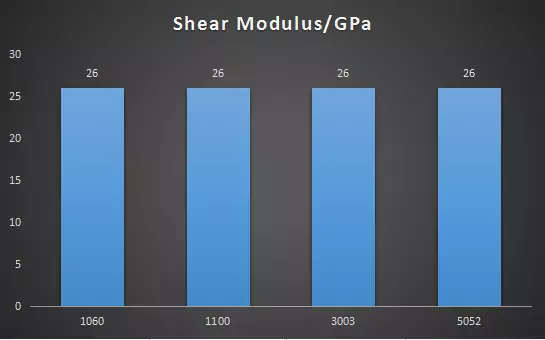

Shear Modulus

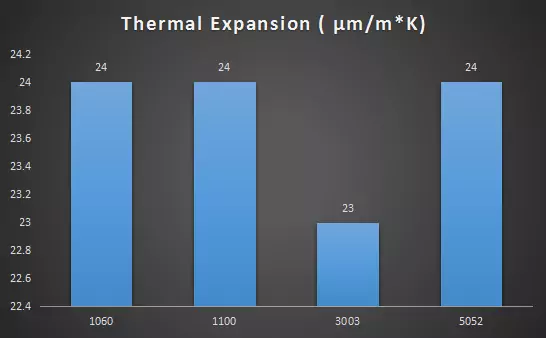

Thermal Expansion

From the above four charts, we can see their similarity. For Elastic(Young’s, Tensile) Modulus, the value for 1060 is 68GPa, 1100 is 69GPa, 3003 is 70GPa, 5052 is 68GPa. For Shear Modulus, the value for all of these four alloys is 26GPa. For Poisson’s Ratio, the value is 0.33. For Thermal Expansion, the value for 1060, 1100 a 5052 is the same, 24 μm/m*k and 3003 is 23μm/m*k.

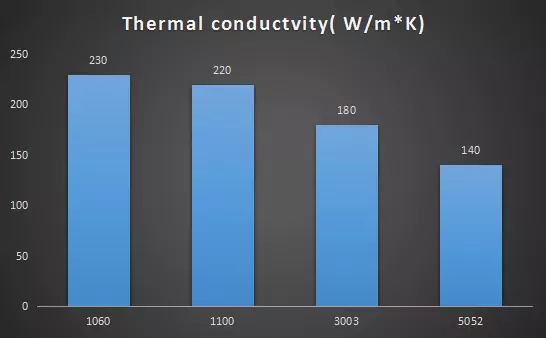

Lastly, let’s take a look at the Thermal Conductivity.

Thermal Conductivity

As aluminum is a material with good thermal conductivity, a 1060 has more than 99.60% konumohe, so it is no wander that it will top the list. And as 5052 contains the least aluminum, its value is the lowest.

Whakamutunga

I roto i tenei tuhinga, we try to show the difference between the six most widely used aluminum tempers in aluminum panel industry. Though 5052H32 leads all the time, but due to its high scrap rate, low thermal conductivity and many other factors, people don’t always choose 5052 as the material of aluminum panel. And as 1060 a 1100 contain big amount of aluminum, their price is lower than 3003 a 5052. Normally, if for personal buyers, Alumideas recommends 1060 a 1100. And for 3003, it is a good choice for governmental projects such as railways, airports and many other projects as it succeeds 1060 a 1100 is many properties with a low scrap rate.

Kei te rapu i tetahi kaiwhakarato mata mo o kaupapa?

Ko Alumideas he kaiwhakanao hanga i Haina. Ka whakaratohia e matou he otinga kotahi-mutu mo o kaupapa whakakai whakapaipai o roto me waho. Tonoa he korero inaianei!

Ka whakapā atu matou ki a koe i roto 1 ra mahi, kia aro mai ki te imeera me te kumara "@ Www.alumideas.com".