In the aluminum sheet industry, both fluorocarbon paint and polyester paint have their audiences. This article introduces the similarities and differences between the two, so that readers can have a general understanding of fluorocarbon paint and polyester paint, so as to have a reference basis when choosing the surface treatment of aluminum plates.

Section of content

To make sure that you can find the information you want quickly, just click on the content directory below.

1.Difference

Composition

Fluorocarbon paint, commonly seen as PVDF, is a kind of paint uses kynar-500 and hylur500 as base materials. It is processed from 70% of fluorocarbon resin and 30% of acrylic resin, pigments, and additives. As the resin molecule contains the C-F bond with the highest bond energy in the organic medium, the fluorocarbon paint coating has many special properties that are superior to ordinary coatings. Among many types of coatings, PVDF coatings have excellent properties due to the large electronegativity of the introduced fluorine element and strong carbon-fluorine bond energy. Weather resistance, heat resistance, low temperature resistance and chemical resistance are some of its advantages. Moreover, it has unique non-stick and low friction properties, and it is difficult for dirt to adhere to the surface, which is very suitable for the decoration of outdoor walls.

Polyester paint consists of three components: main paint, thinner and curing agent: the main agent is a styrene solution of unsaturated polyester, and there are also initiators (also known as curing agents, hardeners) and accelerators. The unsaturated double bond in the main chain of the saturated polyester undergoes a radical copolymerization reaction with an ethylenic monomer (styrene) as an active solvent, and is cured to form a film.

Polyester paint uses polyester resin as the main film-forming material. Polyester paint is also called Unsaturated polyester paint. It is a multi-component paint and a thick paint made of polyester resin as the main film-forming material. The paint film of polyester paint is plump, and the layer is thick and the surface is hard. Polyester paint also has varnish varieties, called polyester varnish. Polyester paint needs to be cured during the construction process, and the amount of these curing agents accounts for one-third of the total amount of paint. These curing agents are also called hardeners, and their main ingredient is TDI (toluene diisocyanate).

Appearance

From the appearance effect, the fluorocarbon paint is inferior to the polyester topcoat in terms of brightness. The gloss of polyester topcoat can reach about 95°, while the fluorocarbon paint can only reach about 80°.

Polyester paint is generally divided into: high-gloss, bright, semi-matte, matte. Currently the most popular is matte paint. According to the appearance of the coating film, paint is divided into: varnish, color paint; dull, matte, high-gloss, hammer paint, etc. Matte paint is mainly made of varnish, mixed with an appropriate amount of matting agent and auxiliary materials. Due to the different amount of matting agent, the gloss of the paint film is also different. Matte paint film gloss is soft, uniform, smooth, temperature-resistant, water-resistant, acid-alkali-resistant. High-gloss paint is a high-grade interior decoration special interior wall paint, specially used for interior cement wall, masonry, gypsum, ceiling, Surfaces such as wood structures.

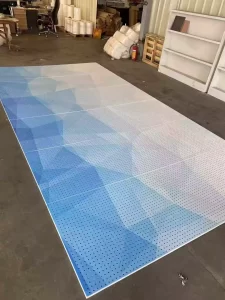

High gloss polyester painted panels

High gloss polyester painted panels

Weather resistance

Although both PVDF and polyester paint have excellent weather resistance, they are still slightly different. In the same outdoor environment, fluorocarbon paint has better gloss retention and anti-corrosion and anti-rust effects than polyester topcoat. The former can maintain a service life of 10-15 years, while the latter is only about 8 years, or even shorter if the quality of the paint is poor.

Self-cleaning

In terms of self-cleaning properties of paint films, fluorocarbon paints also have certain advantages. The surface of fluorocarbon paint is not easily contaminated with dust, oil, etc., and is easy to clean. Polyester topcoats do not have this feature.

Price

Price is always a key factor when making decision. The polyester topcoat has a huge advantage in terms of price. It is nearly half of that of PVDF paint.

Similarity

The biggest similarity between PVDF and polyester paint is their spraying steps and coating thickness.

The first step of polyester paint spraying on aluminum veneer is to paint the primer coating. Primer coating is the primer decoration of the aluminum veneer substrate. This layer is used as an inherent protection, mainly aims to improve the penetration resistance of the coating when further finishing. The aluminum veneer material is protected by primer painting. In this way, the surface effect of the material can be stabilized, the finishing effect has good uniformity, and the adhesion effect between the topcoat material and the metal plate can be improved. Generally, the thickness of the primer is controlled at about 5-10 microns.

The second step is topcoat coating. The topcoat coating can not only add decorative effect to the appearance, but also beautify the aluminum veneer material, making it more suitable for the needs of building decoration. At the same time, top coat can prevent the aluminum veneer material from directly contacting the outside air, so that it is not attacked by acid rain, pollutants, etc., and delays the aging speed of the material. Generally, the thickness of the topcoat is required to be controlled at about 20-30 microns.

The third step of varnish coating. The main reason for the varnish treatment is to increase the anti-invasion ability of the coating to the external environment, to better protect the integrity of the topcoat coating, to enhance the gloss effect of the surface. The thickness of the varnish coating is generally required to be around 5-10 microns.

The next step is curing treatment. This step requires keeping the aluminum alloy material in the curing furnace for high temperature consolidation, and the temperature is controlled between 180-250 degrees Celsius. Different aluminum veneer manufacturers will control the temperature and time to a certain extent according to the materials they produce.

Conclusion

Fluorocarbon paint and polyester paint can both be used indoors and outdoors, which is one of the similarities between the two, but there are also subtle differences. Fluorocarbon paints are more used outdoors because of their anti-yellowing, weather-resistant characteristics, corrosion and weather resistance, and UV resistance and many other properties. Polyester paint is more used indoors.

It should be noted that polyester paint needs to be cured during the construction process, and the amount of these curing agents accounts for one-third of the total amount of paint. These curing agents are also called hardeners, and their main ingredient is TDI (toluene diisocyanate). These free TDI will turn yellow. At present, yellow-resistant polyester paints have appeared on the market, but they can only be “yellow-resistant”, and cannot completely prevent yellowing. In addition, free TDI beyond the standard will cause harm to the human body. The harm of free TDI to the human body is mainly sensitization and stimulation. The international limit for free TDI is controlled below 0.5%.

Considering that polyester paint will turn yellow and may cause harm to human body, although it is superior to fluorocarbon paint in terms of price and appearance, the long service life and other superior properties make fluorocarbon paint the first choice for aluminum panels customers.

PVDF ACP

Looking For a Facade Supplier For Your Projects?

Alumideas is a aluminum facade manufacturer in China. We provide a one-stop solution for your interior and exterior decorative cladding projects. Ask for a quote now!

We will contact you within 1 working day, please pay attention to the email with the suffix “@www.alumideas.com”.