Introduction aux panneaux de façade en aluminium

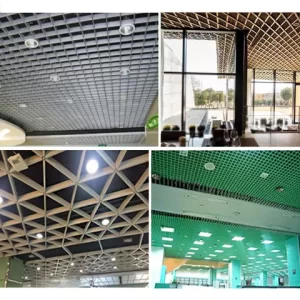

- La structure des panneaux de façade en bardage aluminium est principalement constituée de cadres d'installation, panneaux en aluminium, nervures de renfort, et codes de coin. Les codes d'angle peuvent être directement pliés et formés à partir des panneaux, ou les codes d'angle peuvent être rivetés sur les petits côtés des panneaux.

- Les avantages incluent un attrait visuel élégant, durabilité, flexibilité de conception, facilité d'installation, et peu d'entretien.

-

Les applications vont des tours de grande hauteur aux magasins de détail en passant par les résidences modernes.

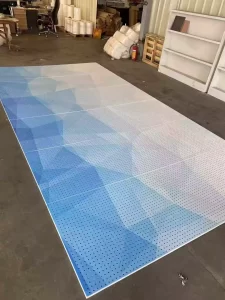

- Il existe plusieurs options telles que le revêtement en poudre, impression numérique, gaufrage, et perforations.

- L'aluminium est léger mais suffisamment solide pour une installation de revêtement de façade à grande échelle. Il peut également être façonné en formes 3D.

Table des matières

Choisir le bon fabricant de panneaux de façade en aluminium

Le fabricant que vous choisissez peut faire ou défaire le succès de votre projet. Évaluer de manière exhaustive les fournisseurs à travers:

Expérience et expertise

- Recherchez des entreprises matures avec 10-15+ années consacrées à la construction de panneaux architecturaux en aluminium.

- Ils doivent présenter des projets de revêtement antérieurs d'une complexité comparable à la vôtre..

- Une vaste expérience de projet se traduit par un savoir-faire technique au service de votre projet.

Capacités de conception personnalisées

- Les meilleurs fabricants proposent des revêtements personnalisés adaptés à la vision esthétique unique de chaque projet..

- Évaluer leurs travaux antérieurs pour évaluer la flexibilité avec les couleurs, motifs, formes, tailles de panneaux, et d'autres facteurs.

- Peuvent-ils fabriquer les conceptions complexes que vous envisagez? Proposent-ils plusieurs concepts?

Certifications de qualité et de tests

- Les fabricants réputés suivent une gestion stricte de la qualité et respectent les normes.

- Renseignez-vous sur les certifications de qualité tierces comme ISO 9001.

- Examiner les données de test – leurs panels d’échantillons valident-ils le respect des exigences structurelles, charge de vent, acoustique, and other performance levels?

Warranties

- Quality claddings should have a 10-15 year product warranty.

- Ensure warranty terms suit your needs.

- Avoid very short warranties or no warranty – these often indicate questionable quality.

Durabilité

- Many architects prioritize eco-friendly materials.

- Check on recycled content and recyclability of the aluminum.

- Also, look for low VOC coatings and other green practices.

Manufacturing Capabilities

- Assess capabilities like monthly capacity, fabrication precision, welding results, and finish options.

- Tour their factory if possible to see facilities. Capabilities limit design possibilities.

Factory Location and Logistics

- For domestic projects, closer proximity between site and factory reduces shipping costs and lead times while improving construction coordination.

- For international projects, les fournisseurs situés plus près des ports peuvent réduire les délais et les coûts d'expédition pour accélérer le calendrier.

- For international projects, une riche expérience en matière d'exportation et de dédouanement peut rationaliser la logistique pour un transport efficace.

Exemples de projets pertinents

- Demander des études de cas de façade de bardage au fournisseur, en particulier les panneaux en aluminium dans votre région et type de bâtiment si disponible.

- Cela démontre la capacité éprouvée à fournir avec succès des étendues similaires..

Demander des devis

Une fois que vous avez réduit la liste des fabricants, des devis peuvent être demandés. Préparer une demande de prix complète comprenant:

Conception Intention

- Fournir des dessins CAO, images conceptuelles, rendus, spécifications, et des détails pour transmettre les fondamentaux. Plus les fournisseurs comprennent le projet, mieux ils pourront fournir des conseils et des solutions sur mesure.

- Cela inclut les dimensions, dispositions des panneaux, visages décoratifs, et tous les aspects personnalisés. Plus de détails, c'est mieux.

Exigences de performances

- Spécifier la structure requise, charge de vent, infiltration d'eau, acoustique, thermique, tolérance, et autres normes de performance technique.

- Inclure les codes et normes de construction pertinents à respecter.

Chronologie du projet

- Décrire les étapes du projet, y compris les phases de conception, approvisionnement, fabrication, livraison, et mise en place.

- Comprendre les délais de fabrication en fonction de la complexité. Les conceptions plus complexes prennent plus de temps à produire.

Objectifs de durabilité

- Partagez tous les objectifs de durabilité comme le contenu recyclé, efficacité énergétique, ou certifications de bâtiments écologiques recherchées.

Installation

- Fournir des attentes détaillées concernant le système d’installation prévu et les accessoires requis. Ou demandez conseil au fournisseur sur les systèmes et approches d'installation conventionnels.

- Y a-t-il des restrictions logistiques?

Échantillons

- Demander des échantillons, modèles, rendus numériques, ou d'autres visuels à évaluer.

- Les fournisseurs peuvent fournir des prix préliminaires sur les échantillons.

Durée de vie du produit

- Renseignez-vous sur la durée de vie prévue, besoins d'entretien, et conditions de garantie.

- Les façades en bardage aluminium sont un investissement à long terme.

Les fabricants peuvent fournir des devis précis grâce à une demande détaillée prenant en compte tous les facteurs ayant un impact sur le coût et la faisabilité..

Évaluation des devis et des alternatives

Quand les devis sont reçus, examiner attentivement chaque détail, y compris:

Tarifs

- Comparer les prix entre fournisseurs. Le moins-disant est souvent trop beau pour être vrai en termes de qualité. Visez le milieu.

- Obtenez des détails sur le matériel, fabrication, fabrication, logistique, et frais d'installation.

- Attention aux frais cachés.

Délais

- Évaluer les délais de livraison et la durée du projet.

- Assurez-vous que le calendrier correspond à votre feuille de route de construction.

- Tamponner les retards potentiels.

Caractéristiques

- Vérifier que les spécifications du devis correspondent à celles décrites dans la demande.

- Rechercher des explications si des éléments sont manquants ou inadéquats.

Warranties

- Évaluer l’exhaustivité, longueur, et conditions de garanties entre fournisseurs.

- Des lacunes telles que des franchises élevées ou des exclusions augmentent les coûts réels au fil du temps..

Références et échantillons

- Recueillir les références des fournisseurs sur la qualité et le service.

- Examiner des échantillons physiques pour visualiser les options.

Conditions du contrat

- Comprendre les échéanciers de paiement, modifier les politiques de commande, passif, exigences en matière d'assurance, et autres termes du contrat avant de signer.

Lors de l’analyse des alternatives de devis, considérer la valeur totale à long terme, service, et qualité – pas seulement le prix initial.

Attribution du contrat de revêtement en aluminium

Une fois le bon fabricant sélectionné, compléter l'accord, y compris:

Bon de commande

- Émettre un bon de commande formel qui définit clairement la portée du travail, caractéristiques, prix, et termes et conditions.

- Évitez les engagements verbaux.

Calendrier de paiement

- Les termes typiques sont 40% acompte à la signature du contrat, un solde dû à l'achèvement de la production avant l'expédition.

Logistique

- Déterminez qui coordonne l'expédition et la logistique : les conditions de prix déterminent si les responsabilités en matière de transport et de logistique incombent au client ou au fournisseur..

- Qui est responsable du déchargement?

Coordination des travaux

- Décrire les attentes en matière de collaboration tout au long de la finalisation de la conception, fabrication, et processus d'installation.

- Communiquer les modifications immédiatement pour éviter les retards.

Communication continue

- Désigner les principaux contacts des deux côtés ainsi que les méthodes standard pour les mises à jour des progrès, résolution du problème, et commentaires.

Avec une planification proactive du processus d’approvisionnement et la sélection des bons partenaires, le succès du projet de revêtement de façade devient plus réalisable. Une attention méticuleuse aux détails et aux spécifications permet de tirer parti de la polyvalence de l’aluminium pour créer un style architectural distinctif aligné sur votre vision.. Faites-nous savoir si vous avez besoin de conseils tout au long du processus d'approvisionnement en panneaux de façade en aluminium.!