Aluminum Cladding System Deep Dive: The Architect’s Handbook

Aluminum Cladding System Deep Dive: The Architect’s Handbook Introduction: In this comprehensive guide, we take an in-depth look at everything related to aluminum cladding systems.

At present, under the new situation of energy shortage in the whole society, decorative aluminum wall panels are generally favored by people. Alumideas is a professional aluminum decorative wall panel supplier in China, with over 12 years of experience in aluminum decorative panels manufacturing.

Get an aluminum decorative wall panel quotes in one second:

Certifications

ISO 9001:2015 | SGS certificated | Critical to Quality Inspections

Generally, to simply distinguish indoor and outdoor uses, the thickness of the aluminum panel is the key element. For example, the thickness of the aluminum veneer for the exterior wall is basically required to be above 2.0mm, 2.5mm, and 3.0mm to resist wind and oxidation; For indoor aluminum panel, if it is installed at a height that is out of reach of the crowd, a thickness of 1.5mm can be used, otherwise it is too thin and easy to bump and deform.

Another difference is surface treatment. Since the interior decorative aluminum plate is not corroded by rain and rarely exposed to the sun, it has low requirements for acid and alkali resistance. Therefore, wood grain, stone grain and other watermarked surface treatments can be applied.

Basically, interior decorative aluminum panels can be separated into four types: aluminum column wrap, aluminum privacy screen, aluminum balustrade infill panels, and aluminum interior wall panels.

(Blog: What Is Decorative Aluminum Panel?)

Feature | Specification |

Origin | Made in China |

Brand | Alumideas |

Certified By | ISO9000 International Standards |

MOQ | 80 sq.m |

Price | USD30-USD100/Sq.m |

Packaging | Securely packed with plywood & metal casing, added protection with film and bubble wrap |

Estimated Delivery | Within 15 to 30 days |

Production Capacity | Up to 30,000 sq.m monthly |

Material Composition | Premium Aluminum Alloy |

Recommend Size | 1000mm x 2000mm |

Thickness Options | Between 1.5mm to 10mm |

Surface Options | Choice of Powder Coating or Pvdf Paint |

Available Colors | Versatile palette including all RAL colors, wood, stone, and metallic finishes |

Ideal For | Windows, Fences, Building Facades, Curtain Walls, Decorative Screens, and more |

Maximum Size | Up to 1500mm x 5000mm |

Manufacturing Techniques | Advanced methods including CNC Cutting, Bending, Laser Cutting, Carving, and Engraving |

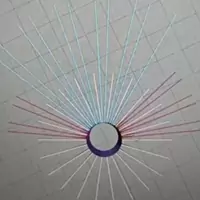

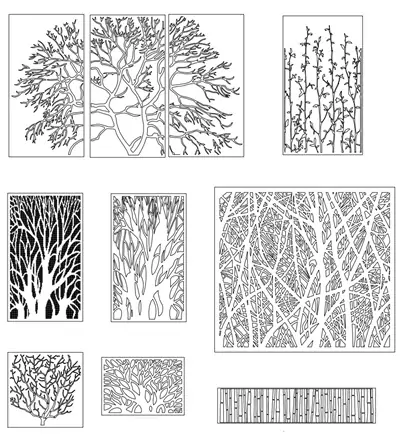

According to aluminum alloy physical properties,1100 and 3003 series are the most common use for the interior decorative panels. The layout pattern design has very high requirements for cutting accuracy. When the engraving machine cannot meet the accuracy requirements, a laser cutting machine is required. The laser cutting machine used by Alumideas is HGTECH brand Laser cutting machine, HGTECH is a world-renowned provider of laser equipment and CNC precision plasma cutting equipment, the production video is as follows:

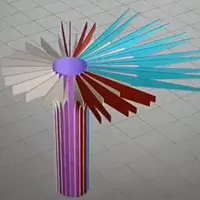

Aluminum column paneling design can be divided into two types: curved aluminum wrap and square aluminum wrap. The shape of the column-coated aluminum veneer depends on the shape of the column. For example, the circular column uses curved aluminum veneers, and the square column uses square aluminum veneers. If you want to decorate the columns, the aluminum column wraps will be a good choice for column paneling design.

The main function of wrap is actually the same as that of aluminum veneer for buildings. There are two main aspects, one is to protect the building, and the other is to have a good decorative effect on the building. The use of column-clad aluminum veneer makes the column more metallic and more modern. In addition to the two functions mentioned above, it also has the advantages of convenient installation and maintenance, and long service life. It is suitable for various large-scale building columns paneling designs.

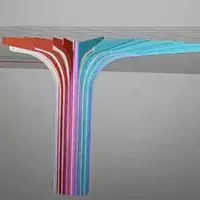

Partition plays a vital role in interior decoration. It frequently appears in offices area, restaurant, drawing room, exhibition spaces or partition designs between drawing and dining. The aluminum partition not only divides the space in the area, but at the same time it does not completely separate the living room like the whole wall. This combination of virtual and real makes the partition a focus for enterprises and architectural designers to show their individuality and talents.

Generally, there are two types of screens: vertical and multi-fold, in transparent, translucent, closed and hollow form. They are generally used for spacing. In different seasons, various textures and different color screens can be applied. For example, in autumn, the color of the screen should be brighter; in summer, light colors should be used to make the room look fresh and cool. In addition to the traditional construction site style, there are hanging screens, furnace screens, telephone screens, etc., and the decoration should be coordinated with the overall home environment.

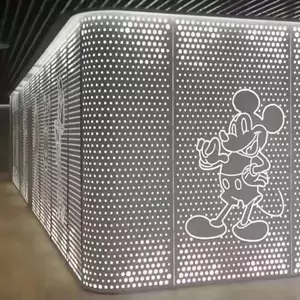

Balustrade infill panels are an essential element for all stairs and handrails. The perforated aluminum sheet is the most popular material for practical and safety purposes among the many options. The products are applicable to be used as individual infill panels, continuous balustrades at a uniform height, or from the first floor to the second floor.

Aluminum sheet balustrade utilizes either solid, perforated or router cut aluminium sheet fitted into the frame. The thickness of the sheet can be decided by the customers. This is a simple & effective way to provide privacy, protection and the aesthetic look from a sheet infill.

It is available in a wide variety of patterns, such as modular punched patterns or laser cut patterns. It’s easily designed to site-specific requirements, mostly used on commercial projects.

The surface of the indoor curtain wall aluminum panels is smooth and flat. Not easy to stick to dust. What’s more, it can achieve a high value of 100% recycling and recovery. It is for this reason that it has been unanimously supported by the majority of users. From its characteristics, as a wall decoration material, not only the effect is obvious, but also the use cost is low, and it has become the preferred material for decoration.

The aluminum interior curtain wall is made of high-quality and high-strength aluminum alloy plates which are mainly composed of panels, reinforcing ribs, and aluminum corner codes. Its popular thickness is 1.5, 2.0, 2.5, and 3.0mm but need to notice that a 1.5mm-thick aluminum veneer should be applied at high places which are out of reach by the crowd to avoid the damage caused by human collision.

Aluminum curtain wall panels can be processed into various complex geometric shapes such as plane, arc, and spherical.

To save you time, we have also prepared PDF versions of all product catalogs, only leave your email and you will get the download link immediately.

Wood grain aluminum veneer is used in various metal curtain wall panels and metal ceiling panels. It is suitable for a variety of living and working places, such as indoor, outdoor, airport, subway, light rail, station, exhibition hall, hospital, administrative office building, commercial building and other places, in line with environmental protection requirements.

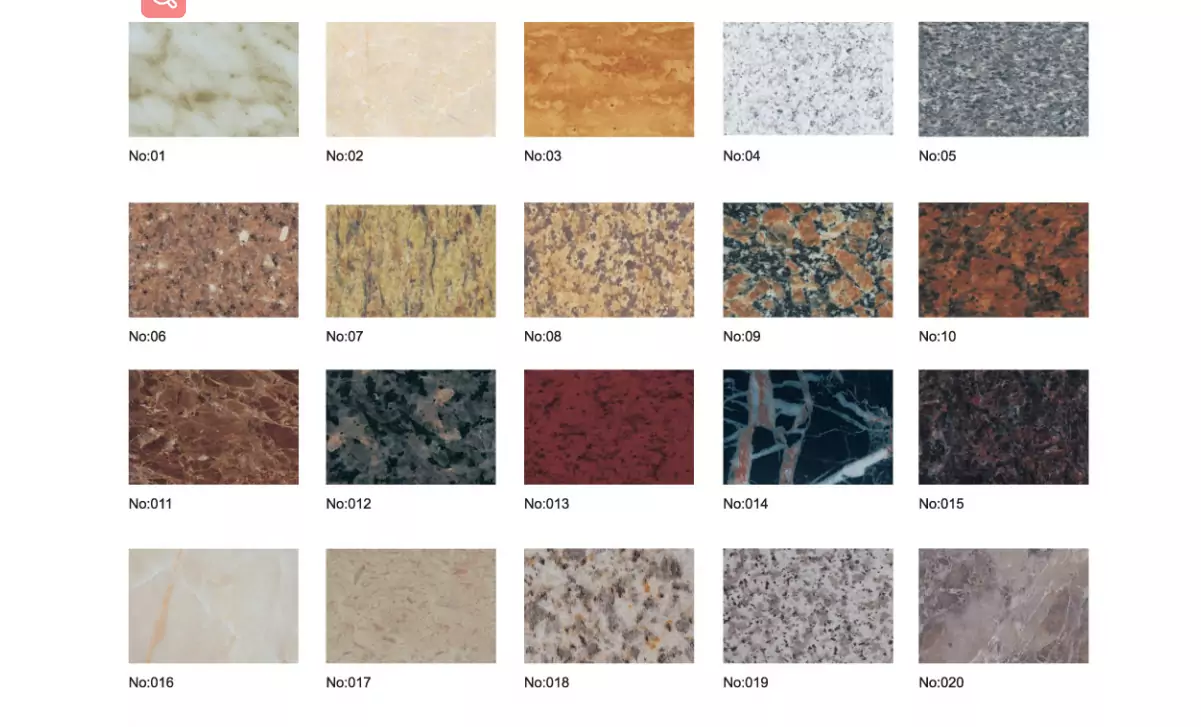

Stone pattern aluminum decorative panel is an aluminum plate with a stone-like effect on the original basis of the aluminum veneer. There are two kinds of stone pattern aluminum panel, one is thermal transfer stone pattern, and the other is fluorocarbon real stone paint. Stone pattern aluminum panel, and stone paint aluminum veneer have natural color exactly looks like a stone, giving people the beauty of elegance, harmony and solemnity. Real stone paint aluminum veneer is suitable for indoor and outdoor decoration of various buildings.

The stone patterns are rich and delicate, and the effect is realistic. The weight per unit area is greatly lower than that of stone, which improves the safety level. It can reduce the difficulty and cost of construction and shorten the construction time. Good toughness, not easy to break, moisture-proof, easy to clean are some of its advantages. It has strong plasticity and can be processed into various complex shapes. The back can be filled with materials such as heat preservation, heat insulation, sound absorption and sound insulation, which has the effect of reducing energy consumption, which is unmatched by stone.

Get an aluminum decorative wall panel quotes in one second:

Shorten your product development cycle by weeks (and sometimes months) and produce panel sample and finish qualification tests within days. Some aluminum veneer samples can be shipped within 3 days.

Each quote includes real-time pricing and design analysis.We evaluate your 3D CAD and help identify any features that may be challenging during the manufacturing process, such as multifaceted folding of special-shaped plates and high precision engraving.In addition, our team of experienced application engineers can discuss your unique design, evaluate cost trade-offs, and even help you optimize aluminum sheet drawings and make design changes through our consulting design services.

We have complete automatic spraying equipment line, temperature control furnace, LPG combustion system and German pretreatment technology. The surface is made of high-quality PVDF coating from PPG, DNT, AKZO, NIPPON and other world-famous PVDF coating manufacturers, with a wide range of colors and can be customized in any color with your color sample

Alumideas has over 60+ oversea project in more than 30 countries for more than 10 years. Familiar with aluminum wall cladding design and installation methods in different countries and able to give professional advice, so as to promote customer’s engineering projects

Aluminum Cladding System Deep Dive: The Architect’s Handbook Introduction: In this comprehensive guide, we take an in-depth look at everything related to aluminum cladding systems.

Choosing the Right Outdoor Aluminum Ceiling panels for Your Building A residential and commercial building is incomplete without a proper roof. It should come as

Discover the benefits and versatile applications of aluminum facade panels in modern architecture. Highlighting their light weight, durability, design flexibility, and crucial role in sustainable building practices, the article underscores the expertise of Alumideas in manufacturing these panels. As a forward-thinking industry leader, Alumideas invites future collaborations.

Get an instant quote from our professional consultants.

We will contact you within 1 working day, please pay attention to the email with the suffix “@alumideas.com”.

Quick Info Exchange Helps Us Serve You Better