In this article we will introduce laser cutting in the aluminum panel engraving process.

How does laser cutting work?

What Alumideas uses is the national enterprise-level fiber laser cutting machine HGTECH GF6025Plus Sheet Metal Laser Cutting Machine.The machine adopts an autonomous fiber laser generator, which provides customers with strong cutting ability and efficiency on aluminum cutting and engraving.Fiber laser is a kind of laser that is based on fiber, uses doped fiber doped with various element ions as working material, and utilizes the nonlinear self-phase modulation effect of fiber.Fiber laser is a multi-wavelength light source, which consists of gain medium, optical resonator and pump source. The gain medium generates photons, the optical resonator enables the photons to be fed back, and the pump source stimulates photon transitions. Fiber lasers have many advantages such as low threshold, high power, high beam quality, good reliability, compact structure and good heat dissipation.

The machine is equipped with a professional laser cutting control system, which uses a computer to operate and control the machine instead of manually adjusting the laser transmitter, which combines high stability, high power, high performance and fast speed.

The power of the laser cutting machine determines the thickness of the aluminum panel that the machine can cut, and the power of the laser cutting machine used by Alumideas covers the range of 1000W-12000W. Therefore, Alumideas can cut aluminum panels with common thicknesses and uncommon thicknesses on the market for you.

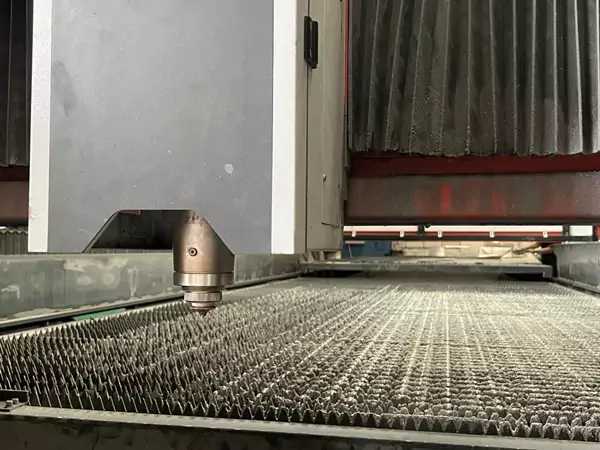

The machine stroke of the laser cutting machine is 2530mm*6050mm, so the area of the aluminum panel that can be cut can reach 2500mm*6000mm, which can cope with most of the aluminum panels on the market. The acceleration of the machine can reach 140m/min, which greatly improves the work efficiency. The machine adopts the upper and lower parallel worktable mode, and the exchange table adopts parallel exchange, which can realize the laser cutting at the front end of the bed, and the material is loaded and unloaded at the back end without interfering with each other, which greatly improves the work efficiency.

The positioning accuracy of the laser cutting machine can reach 0.05Pa*(mm), and the repeat positioning accuracy can reach 0.03Ps*(mm). The positioning accuracy is the accuracy that each motion axis can reach the target setting position under the control of the control system. It reflects the positioning stability of each motion axis of the CNC equipment within the stroke. In the laser cutting equipment, the positioning accuracy of the motion platform will be It directly affects the cutting accuracy of laser cutting equipment. And Alumideas’ laser cutting machine can effectively guarantee the customer’s needs and accurately cut aluminum sheets. And to ensure the high accuracy of the same batch of aluminum panels, to avoid the problem of serious errors in the same batch of goods.

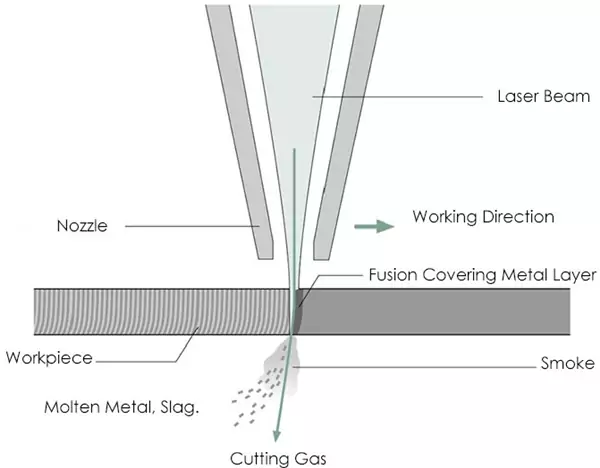

Laser Cutting Operation

At its narrowest point, the diameter of the laser beam is typically less than 0.32 mm, depending on the material thickness, the kerf width can be as small as 0.10 mm.

What we use is a national enterprise-level fiber laser cutting machine, and the power of the laser can reach 1000W-12000W. The acceleration of the machine can reach 140m/min, which greatly improves the work efficiency. The positioning accuracy can reach 0.05Pa*(mm), and the repeated positioning accuracy can reach 0.03Ps*(mm). There is also 2530mm for the cutting width of the panel.

Laser Cutting Machine

Advantages of laser cutting aluminum panel:

- The precision of laser cutting aluminum panelwill be relatively high. The laser cutting incision is narrow and smooth, which means that secondary finishing is not required, there is no rough incision common in mechanical cutting, the thermal influence is small, and the material is deformed. to a lesser extent.

- 2. The speed of cutting aluminum panelwith laser is much faster than that with mechanical cutting. Compared with the same power CO2 laser cutting machine, the speed of fiber laser cutting is twice that of CO2 laser cutting speed

- The material loss is small, and laser cutting mostly uses machine cutting instead of manual cutting, which reduces the occurrence of cutting material errors. The equipment will calculate the inclination angle of the panelwithin 10 seconds, and the coordinate system of the machine tool will rotate accordingly, which solves the problem of low material utilization, saves the time for calibrating the panel, and effectively improves the production efficiency.

- Use lasers to cut aluminum sheets, usually with a computer operating complex software to optimize part paths, machine speed and sheet metal utilization, which means they produce complex precision parts in a repeatable and efficient manner. Part variance between production runs is minimal, so customers’ complex patterns can be cut with precision, effectively reducing error rates and increasing customer satisfaction.

Laser Cut Aluminum Sheet

Disadvantages of Laser Cutting:

Laser cutting does have some disadvantages compared to other manufacturing techniques, including:

- Compared with other cutting methods, the maximum thickness of the fiber laser cutter we use is 30 mm

- The energy and power consumption of maintaining and using the laser cutter will be greater, and the cost will be higher.

- When the thickness of the cut sheet or part is thick, burrs may appear on the cutting edge, which requires manual grinding, which wastes time and manpower.

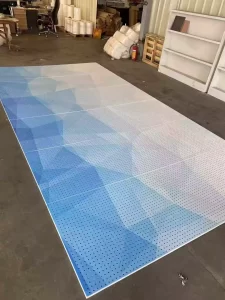

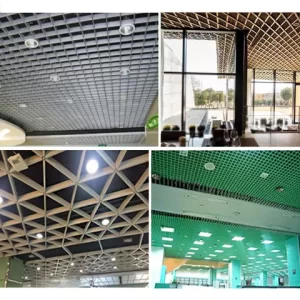

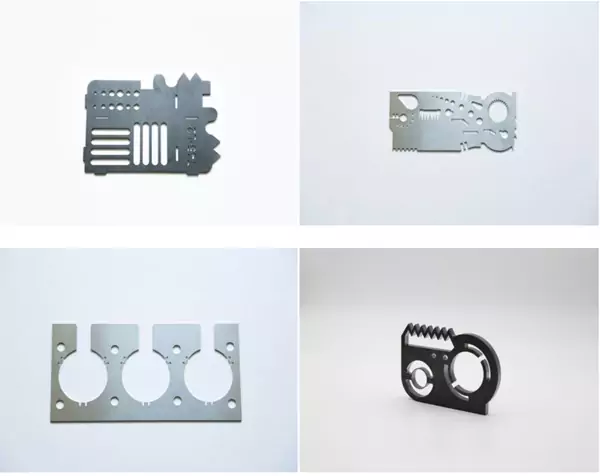

Some pictures of laser cut products:

Video of laser cutting cutting aluminum sheet

Looking For a Facade Supplier For Your Projects?

Alumideas is a aluminum facade manufacturer in China. We provide a one-stop solution for your interior and exterior decorative cladding projects. Ask for a quote now!

We will contact you within 1 working day, please pay attention to the email with the suffix “@www.alumideas.com”.