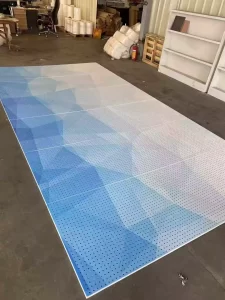

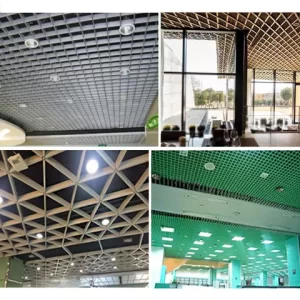

As we all know, perforated panels are very popular products in the field of aluminum panel. This article is to briefly introduce some useful information about the engraving machine which is a vital machine when producing perforated panels.

The engraving machines Alumideas use are named “HDIAO 2040GT” and “HDIAO 2060GT”. Following are details of the machine.

Usually, for the aluminum panel engraving machine, the 2040 model is the most used one. “2040” means the maximum width of the panel that can be processed by the machine is 2000mm; and the maximum length is 4000mm. Attention should be paid here as 100mm means the maximum panel thickness that can be processed by the machine. But according to our experience, 105mm is also acceptable, so actually the maximum thickness is 105mm instead of 100mm.

Features of GT Model:

1) Multi-function: It is a comprehensive machining center for the aluminum veneer industry of aluminum curtain wall. It can be used for high-speed cutting, punching holes, grooving, and embossing.

2) Reduce equipment cost investment: Owning a high-speed aluminum plate machining center is equivalent to owning one milling machine, one punching machine and one slotting machine, which saves the investment cost of equipment.

3) Save plant space and labor: This equipment is multi-purpose, which greatly saves the plant space occupied by the equipment, and can reduce the amount of operators of the two processes at the same time.

4) To optimize the production process, only one positioning and clamping is needed to automatically complete the blanking, punching holes, grooving, and the whole process. Since this machine only needs one-time positioning and clamping, it is superior to the processing method that can be completed by three fixtures required by the traditional production process, which greatly improves the positioning accuracy of processing.

5) Unique automatic programming-free system: It eliminates complicated programming steps, only needs to import CAD drawings into the control system of the engraving machine, and it can be produced through simple settings, which reduces the requirements for operators and facilitates personnel recruitment.

Processing Head:

Currently 5 processing heads are equipped, and the minimum diameter of the head is φ5. That means if you want perforated panels, but the diameter of the hole or any pattern is smaller than 5mm, engraving will not be possible. In this case, another machine—punching machine or laser cutting machine should be used, or modify the diameter to 5mm or above.

Spindle Speed

The relationship between the spindle speed of the engraving machine and the material: the greater the hardness of the engraving material, the lower the spindle speed. This is actually very easy to understand. The material with high hardness needs to be slowly ground, and the tool might be damaged if the speed is too fast. The diameter of the tool used by the engraving machine is also a very important factor in determining the spindle speed. In fact, the diameter of the tool is related to the processing material and the processing line. The larger the diameter of the tool, the slower the spindle speed.

As another article “Comparison of 10 Mechanical Properties of Tempers For Aluminum Panels” in the Blog mentions, the scrap rate of 5052 alloy is high. That’s because of its high hardness which contributes to its longer production time as the spindle speed is low.

The high-speed rotation of the spindle will generate a lot of heat. If the heat is not dissipated in time, it will have a great impact on the service life of the spindle, and in severe cases, the spindle will be burned. There are two main cooling methods for the spindle: water cooling and air cooling.

The Difference Between Air Cooling and Water Cooling

- Water cooling, as the name suggests, uses water circulation to cool the heat generated by the high-speed rotation of the spindle. This effect will be very good, because the temperature of the water after circulation (commonly tested) will not exceed 40 degrees; as the air-cooled spindle uses a fan to dissipate heat, its effect is definitely not as good as water cooling;

- Noise. Basically, when working, the spindle with the water cooling is silent, but that of air cooling is very loud;

- Service life. The water-cooled spindle should pay attention to maintenance, change the water frequently or use an industrial water cooler. The life of such a spindle is much longer than that of an air-cooled spindle!

- Precision. The axial and radial runout of the water-cooled spindle are basically below 0.003 mm, which is far less than that of the air-cooled spindle motor.

- Ease of use. Since the water-cooled spindle needs to be connected to a water pump, a bucket is needed to hold water, and a water pipe needs to be connected. Especially in the cold winter in the north, it is easier to freeze, and some customers may find it more troublesome; while the air-cooled spindle will not have so many usage issues.

Note:

The pump must be completely submerged in clean tap water. Otherwise, the water pump will be damaged. And there should be no metal residues in the water, because the water pump is magnetic, too much metal will affect the quality of the pump.

The next part is introduction of fix-axis machining center, which is also called five-axis engraving machine.

Five-axis Machining Center

Five-axis machining center (five-axis engraving machine) is a machining center with high technology content and high precision especially used for processing complex curved surfaces. It has the characteristics of high efficiency and high precision, and the complex machining can be completed in one clamping of the work piece. Unmatched material removal rates and superior chip evacuation increase productivity.

The five-axis machining center adds a rotation axis and a swing axis to the X, Y, and Z axes. The rotation axis can be the A axis or the B or C axis (the axes that rotate around X, Y, and Z are called respectively A axis, B axis and C axis), the rotation axis can be rotated 360 degrees, and the swing axis is one of the remaining two axes (such as B or C) after the rotation axis has been defined (such as A axis). The swing axis can only swing within a certain angle (such as plus or minus 90 degrees) and cannot rotate 360 degrees.

Therefore, the five axes of the five-axis machining center generally have three modes: XYZAB, XYZAC or XYZBC.

Advantages of Five-axis Machining Center:

1. Maintain the best cutting state of the tool and improve the cutting conditions

The five-axis machining center can rotate the working bar to keep the tool in the best cutting state, and also avoid the situation where the linear speed of the center point of the ball end milling cutter is 0, and obtain better surface quality.

2. Effectively avoid tool interference

The five-axis machining center can use shorter tools for processing, improve the rigidity of the system, reduce the number of tools, avoid the generation of special tools, and effectively avoid tool interference.

3. Reduce the number of clamping, and complete five-sided processing in one clamping

Five-axis machining centers can also reduce datum conversion and improve machining accuracy. In actual processing, only one clamping is required, and the processing accuracy is more easily guaranteed. At the same time, due to the shortening of the process chain and the reduction of the number of equipment in the five-axis machining center, the number of fixtures, workshop floor space and equipment maintenance costs are also reduced.

4. Improve processing quality and efficiency

The five-axis machining center can use the tool side edge cutting, and the processing efficiency is higher.

5. Shorten the production process chain

The five-axis CNC machining center can complete processing, greatly shortening the production process chain, and simplifying production management and planning and scheduling.

6. Shorten the development cycle of new products

Some new product parts and forming molds have complex shapes and high precision requirements. A five-axis CNC machining center with high flexibility, high precision, high integration and complete processing capabilities can well solve the precision and cycle problems of complex parts processing in the process of new product development, greatly shorten the development cycle, and improve the success rate of new products.

Conclusion

This article is to introduce the engraving machines of Alumideas, including some deciding parameters such as the model, processing head and spindle speed, aiming to give a clear picture of the function of the machines to potential customers who want to purchase perforated panels for their home or projects.

According to Chinese national requirements and standards, aluminum veneer with a thickness of less than 2.0mm cannot be used for exterior wall decoration. The aluminum veneer that has been carved and hollowed out has the characteristics of ventilation. And as perforated panels are more likely to be affected by the wind than the ordinary curtain wall aluminum veneer, if the thickness is too thin, deformation will occur. It is recommended that the thickness of the carved hollow aluminum veneer used for outdoors should be controlled at more than 2.5mm.

Looking For a Facade Supplier For Your Projects?

Alumideas is a aluminum facade manufacturer in China. We provide a one-stop solution for your interior and exterior decorative cladding projects. Ask for a quote now!

We will contact you within 1 working day, please pay attention to the email with the suffix “@www.alumideas.com”.