Aluminum facade panels are a type of metal panel used in building exteriors. They are made from aluminum, which is a lightweight and durable material. They can be easily shaped and customized to create unique architectural designs. Aluminum facade panels are commonly used in commercial, residential, and institutional buildings to enhance the aesthetic appeal and provide protection to the structure.

Certifications

ISO 9001:2015 | SGS certificated | Critical to Quality Inspections

| Capability: | 1,200,000 square meters/Year |

| Material: | 1100H24 / 1060H24 / 3003H24 / 5005H24 |

| Thickness: | 1.0 ~ 5.0mm are all available |

| Size: | 600*600 / 600*1200mm / 1220*2440mm(standard size)/ customized size |

| Suraface: | Roller coating / PVDF coating / Powder coating |

| Tolerances: | Typically, Alumideas can maintain machining thickness tolerance of ±0.2mm and length or width tolerance of ±2mm. |

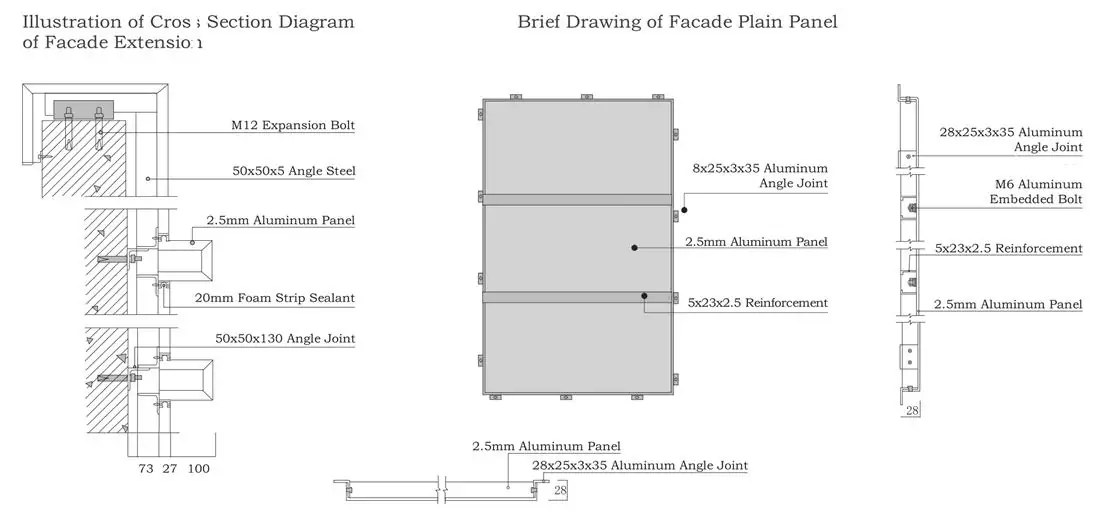

About how to install aluminum facade panels, as a facade panel manufacturer, we will offer fully guideline to our customers, here’s the installation short introduction:

1. Use vertical transportation equipment such as elevators to transport aluminum plates and accessories to each construction node.

2. The whole aluminum plate is connected with the keel through the surrounding aluminum corner codes (brackets) and fixed on the keel.

3. Fixing method: If it is built-in seamless splicing, drill at the corresponding position on the keel, and then riveted with a flat head (countersunk head) aluminum rivet; If it is seam splicing, use steel drill tail screws (also known as flange screws or phoenix screws) to directly drill into the keel through the holes of the aluminum corner code to stabilize the aluminum plate, but pay attention to control the tightness of the drill bit.

4. When trial assembly, pay attention to the installation accuracy, and adjust the aluminum plate before fastening.

5. When installing, the aluminum plate should be installed on the wall according to its serial number.

6. The installation of aluminum plates always starts from the front, large area, and corner parts, and is installed from top to bottom.

7. The connection between the aluminum plate and the keel must meet the requirements of the drawings, it must be firm and stable, and bolts must be installed.

We help you avoid the pitfalls and provide you with durable and cost-effective solution on time and within budget.

Quick Info Exchange Helps Us Serve You Better

Get an instant quote from our professional consultants.

We will contact you within 1 working day, please pay attention to the email with the suffix “@alumideas.com”.