Ipinagmamalaki ng mga alumideas ang isang koponan ng mga bihasang at sertipikadong inhinyero, mga designer, mga consultant sa pagbebenta, at mga eksperto sa produksyon, malalim na nakatuon sa pananaliksik at pagbuo ng mga cutting-edge aluminyo wall-cladding solusyon. Here’s the project processing for construction engineer. Nilagyan ng makabagong makinarya at mga tool, kami ay mahusay sa pagsasagawa ng sopistikadong mga pagsubok, produksyon ng, at mga proseso ng paghahatid. Sa huli, Ang aming misyon ay upang ibahin ang anyo ng iyong mga pangitain sa arkitektura sa mga nasasalat na obra maestra.

Sumisid nang malalim sa isang komprehensibong pagsusuri ng disenyo ng arkitektura na isinasaalang alang mo, focusing on the style and the overall structure of the aluminum panels.

A customized financial roadmap for your project, considering all variables such as materials, design optimizations, and surface treatments. This plan ensures cost-effectiveness while meeting specific project requirements.

An in-depth study of the project’s location, considering factors like local weather and terrain, to make informed choices that ensure the project’s success and durability.

We offer a comprehensive installation manual for aluminum plate mounting, encompassing step-by-step procedures, best practices, and expert recommendations to ensure a seamless and secure setup for optimal performance

Tinitiyak ng aming pangako na ang mga proyekto ay hindi lamang sumunod sa pinakamataas na pamantayan ng kalidad ngunit naihatid din sa loob ng itinakdang timeframe, pagtiyak ng walang pinagtahian na progreso ng proyekto at kasiyahan ng kliyente.

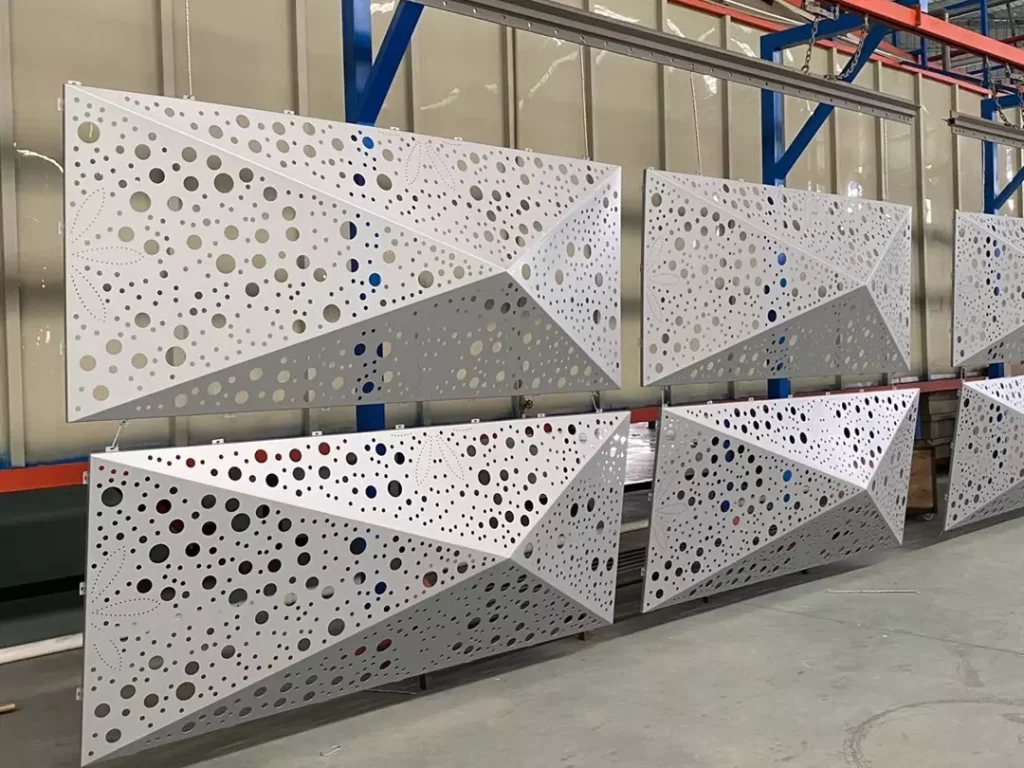

Hindi mahalaga kung ano ang estilo ng aluminyo panel na gusto mo, pwede natin itong manufacture ayon sa ating mayamang karanasan.

Sa partikular na, Sinusuportahan ng aming kagamitan ang espesyal na craftsmanship, na ginagawang mas magkakaibang ang pangwakas na mga produkto kaysa sa karamihan ng mga panel ng aluminyo sa merkado.

Tinutulungan ka naming maghatid ng kalidad at mahalagang mga panel ng aluminyo para sa iyong mga proyekto, sa oras at sa budget.

Mabilis na Info Exchange Tumutulong sa Amin na Maglingkod sa Iyo Mas mahusay

Kumuha ng isang instant quote mula sa aming mga propesyonal na consultant.

Makikipag ugnayan kami sa iyo sa loob ng 1 araw ng pagtatrabaho, paki pansin po sa email na may suffix "@alumideas.com".