Ko Alumides te whakanui i te roopu o nga miihini whaihua me te tohu, nga kaihoahoa, Kaitātaki hoko, me nga tohunga whakaputa, I tino whakapau kaha ki te rangahau me te whanaketanga o te tapahi-aluminum Aluminum Wall-Clations. Anei te tukanga kaupapa mo te miihini hanga. Taputapu me te miihini-a-te-toi me nga taputapu, He mohio ki te mahi i nga whakamatautau ngawari, huānga, me nga tukanga tuku. Whakamutunga tonu, Ko ta maatau misioni ko te whakarereke i nga kitenga o nga hoahoanga ki nga tohu mohio.

Ruku hohonu ki te aro mātai i te hoahoa hoahoanga e whakaarohia ana e koe, Ko te arotahi ki te taera me te hanganga katoa o nga papa konumohe.

He Roadmap putea kua whakaritea mo to kaupapa, Whakaarohia nga taurangi katoa penei i nga taonga, Hoahoa Whakaaetanga, me nga maimoatanga mata. Ma tenei mahere ka whakarite te utu mo te utu i te wa e whakatutuki ana i nga whakaritenga kaupapa motuhake.

He rangahau hohonu o te waahi o te kaupapa, te whakaaro ki nga mea penei i te rangi me te whenua o te rohe, ki te whakatau i nga whiringa mohio e whakarite ana i te angitu me te pumau o te kaupapa.

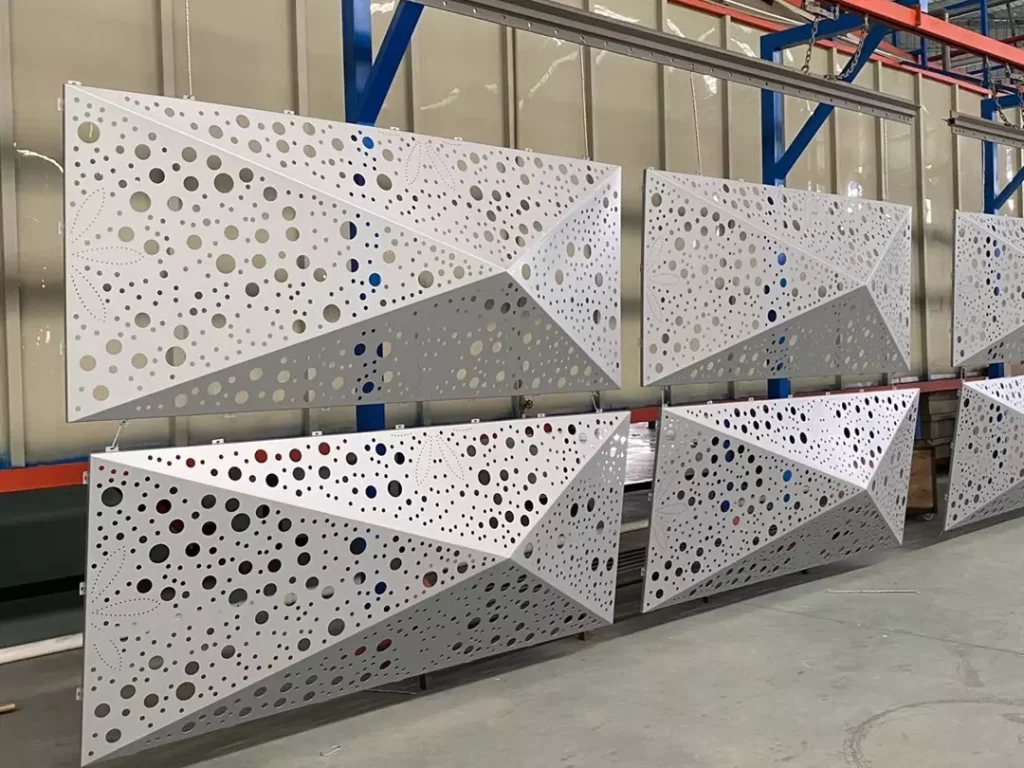

Ka whakaekea e matou he pukapuka whakaurunga whaanui mo te papa pereti konumohe, Kei roto i nga waahanga taahiraa-i te-taahiraa, Nga mahi pai, me nga taunakitanga tohunga ki te whakarite i te huinga koretake me te haumaru mo te mahi tino pai

Ko ta tatou taunga e whakarite kia tutuki nga kaupapa ki nga paerewa kounga teitei engari ka tukuna ano hoki i roto i te waa kua oti te whakarite, te whakarite i te ahunga whakamua o te kaupapa me te makona o te kiritaki.

Ahakoa he aha te ahua o nga papa konumohe e hiahia ana koe, Ka taea e taatau te hanga kia rite ki ta tatou wheako nui.

Ina ake, Ka tautokohia e o maatau taputapu nga mahi motuhake, e hanga ana i nga hua whakamutunga nui atu i te nuinga o nga papa konumohe i te maakete.

Ka awhina matou ki te whakaputa i te kounga me te nui o nga papa konumohe mo o kaupapa, I te waa me te tahua.

Ko te Whakawhitinga Korero Tere ka awhina i a maatau ki te mahi pai atu ki a koe

Tikina he korero tere mai i a maatau kaitohutohu ngaio.

Ka whakapā atu matou ki a koe i roto 1 ra mahi, kia aro mai ki te imeera me te kumara “@alumideas.com”.