This article is to introduce aluminum panel punching, which is also called CNC turret punch in aluminum panel industry.

What is CNC turret punch?

CNC turret punching machine is mainly used for aluminum punching panel forming and processing, which can realize the functions of punching, stretching and forming of aluminum punching panel. The thickness of processed aluminum punching panel is between 0.5 ~ 6mm. The turret is the machine tool mold library, which is equipped with multiple sets of molds. Since the stamping mold is divided into upper and lower molds, the turret is accordingly divided into upper and lower turrets. The upper mold part of the mold is mounted on the upper turret, and the lower mold part is mounted on the corresponding position of the lower turret, and the molds are fixed by bolts. The servo system of X, Y axis and its transmission mechanism constitute the working platform of the turret punch, and various movements are realized under the control of the numerical control system.

Parameters

General thick turret molds are generally classified according to the aperture size that the mold can process, which is convenient for mold selection. It is usually divided into A, B, C, D, E five gears.

A type (1/2″) MAX diameter 12.75mm 18 (4 accept shaped tools)

B type (1-1/4″) MAX diameter 31.75mm 10 (10 accept shaped tools)

C type (1-1/4″) MAX diameter 31.75mm 2(2 AUTO. INDEX)

D type (2″) MAX diameter 50.8mm 2 (2 accept shaped tools)

E type (3-1/2″) MAX diameter 88.9mm 2 (2 accept shaped tools)

Max Sheet Size: 1250*4980mm

Max Sheet Thickness: 6.35mm

Punching Speed at 25mm pitch hits: 360/min

Nibbling Speed (stroke length 4mm, pitch 1mm) hits: 650/min

Max Punching Diameter: 88.9mm

Punching Precision: ±0.1mm

How it works?

When the CNC turret punch press works, the clamp system fixes the aluminum panel on the moving beam of the worktable. The CNC system performs real-time motion control of each axis by decoding the CNC machining program and outputting control signals. The clamps fix the aluminum panel and move on the worktable, and achieve accurate positioning. Then the control system sends out the punch action command to complete the stamping work. The entire processing is completed in accordance with the numerical control processing code sequence.

The CNC turret punch mainly performs point processing of the two-dimensional plane. The working speed of the high-efficiency CNC turret punch can reach 100-150 r/min. From the characteristics of stamping processing, it is known that the aluminum panel needs to be accurately positioned during the stamping process. Kaya nga, the real-time requirements of the numerical control system are very high. After inputting the electronic drawing document of the work piece into the computer, the automatic programming software will quickly generate the machining program of the machine tool, and the machine tool will complete the automatic positioning, die selection and stamping of the aluminum panel under the coordination and command of the numerical control system.

Some special molds

The machine tool has a positioning table in the X/Y direction for positioning the aluminum punching panel, which can send the aluminum punching panel into the striking position; the turret-type mold library can install dozens of sets of molds, and the turret rotates to locate the selected mold to the striking position, and the stamping mechanism drives the stamping die to complete the stamping. The mold structure is very simple, but through the positioning of the aluminum punching panel and the combination of the mold, various hole patterns can be punched out on the aluminum punching panel, and the stroke numerical control of the stamping mechanism can complete various shallow or deep pattern. There are various types of molds, here are only a few special molds:

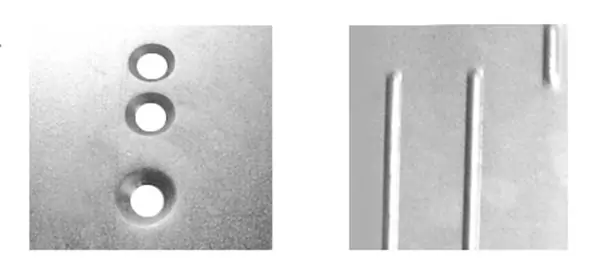

1. Porous die

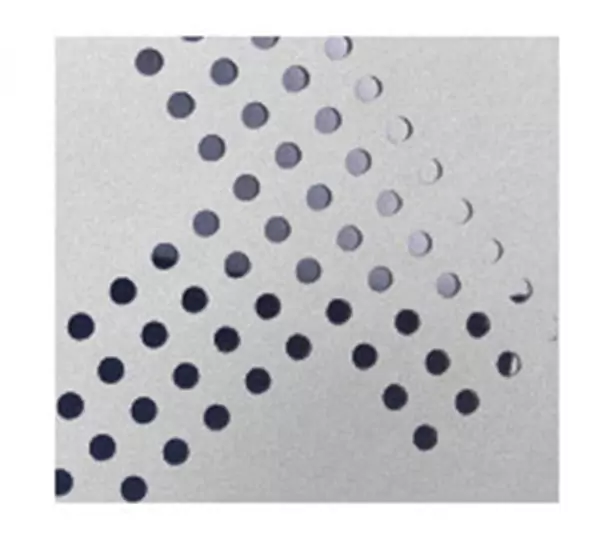

Porous die means that a pair of die can punch multiple holes at the same time. For aluminum punching panels, the efficiency can be improved several times when using porous die. When making a porous mold, it should be ensured that the minimum distance between the holes and the edge of the aluminum punching panel should not be less than twice the thickness of the aluminum punching panel. If the distance is too small, it will cause distortion and deformation of the aluminum punching panel, which will affect the processing effect. Bukod pa sa, the connection between them is also easy to break.

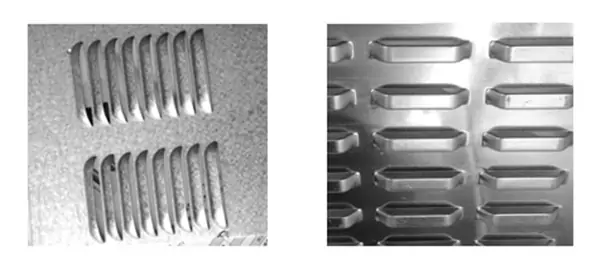

2. Shutter molds and bridge molds

Shutter molds and bridge molds are punching and stretching molds, and they are common molds for cabinets.

3. Countersink dies and bead dies

Countersink dies and bead dies belong to extrusion molding dies. The rib-pressing die is mainly used to press the small arc groove on the flat surface to equal the reinforcing rib effect of the board surface, and the processing is simple and beautiful. Figure 2 is the effect diagram of the countersinking die and the rib-pressing die.

Pangwakas na Salita

This article mainly introduces the turret punch from the four aspects of what is a turret punch, the parameters of the turret punch, how it works, and some special molds.

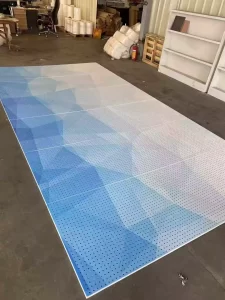

Aluminum punching plate is a widely-use aluminum plate in aluminum panels industry, so it is very necessary to understand the relevant knowledge. Lastly, please watch the video to see the whole process of punching.

The whole process of punching

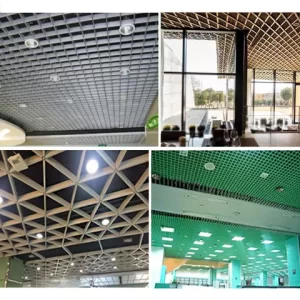

Sa mga Alumideas , our products are widely used for exterior and interior in architecture and building, shopping mall, ospital, metro station, railway station etc. For multifunctional advantage like ventilation, decoration, partition, excellent in lights transmission and so on.

If any requirement for Aluminum decorative panel please contact us ! We will offer the best quote and service !

Naghahanap Para sa isang Facade Supplier Para sa Iyong Mga Proyekto?

Alumideas ay isang aluminyo facade tagagawa sa Tsina. Nagbibigay kami ng isang one stop na solusyon para sa iyong panloob at panlabas na pandekorasyon cladding proyekto. Humingi ng quote ngayon!

Makikipag ugnayan kami sa iyo sa loob ng 1 araw ng pagtatrabaho, paki pansin po sa email na may suffix "@www.alumideas.com".