ACP typically refers to a panel with two aluminum sheets bonded to a polyethylene core, while ACM is often described as a broader term that can include panels with a fire-resistant core, such as mineral-filled polypropylene. This core difference is central to many of their varying properties.

Table of Contents

This detailed comparison aims to address the nuances between Aluminum Composite Panel (ACP) and Aluminum Composite Material (ACM), focusing on their definitions, compositions, and various properties relevant to construction and purchasing decisions. Given the potential intent for purchasing, this analysis covers at least 10 aspects, including application scenarios, to provide a comprehensive overview.

Definitions and Composition

- ACP (Aluminum Composite Panel): Typically defined as a panel consisting of two thin aluminum sheets bonded to a polyethylene core. This structure is common in standard construction applications.

- ACM (Aluminum Composite Material): Often used as a broader term, ACM can refer to any composite material with two aluminum sheets and a core, frequently specifying a fire-resistant core like mineral-filled polypropylene.

The composition is crucial, with ACP’s polyethylene core being lighter and less fire-resistant, while ACM’s fire-resistant core enhances safety but may add weight.

Fire Resistance

Fire resistance is a significant differentiator:

- ACP: Research suggests ACP, with its polyethylene core, has a lower fire rating, often classified as flammable under standards like ASTM E-84 (Class C or lower) or EN 13501 (B or C). This makes it less suitable for high-risk environments.

- ACM: The evidence leans toward ACM having a higher fire rating, often achieving Class A or B in US terms, or A2 in European standards, due to its fire-retardant core, making it ideal for buildings requiring stringent fire safety, such as high-rises or hospitals.

For example, sources indicate ACM is chosen for projects with strict fire regulations, like educational institutions, due to its ability to contain fire.

Durability

Both materials are durable, with aluminum providing corrosion resistance. However, ACM might have an edge due to its potentially more stable fire-resistant core, though specific data on long-term performance is limited. Both can last over 30 years with proper maintenance.

Weight

- ACP: Lighter due to the polyethylene core, with weights around 2.5 lbs/ft², making it easier to handle and install.

- ACM: Slightly heavier due to the denser mineral-filled core, which could impact transportation and installation costs but is still lightweight compared to solid aluminum.

This difference is evident in product specifications, where ACP’s core density (around 0.9 g/cm³ for polyethylene) contrasts with ACM’s denser fire-resistant materials.

Cost

- ACP: Generally less expensive, suitable for budget-conscious projects, as it uses standard materials.

- ACM: More costly due to the fire-resistant core and additional manufacturing processes, reflecting its enhanced safety features. Sources highlight that fire-rated materials like ACM are priced higher, impacting overall project budgets.

Installation

Both ACP and ACM are installed using similar methods, such as field-fabricated or shop-fabricated systems, involving panel attachment to structures. There are no significant differences noted, though ACM might require additional care to maintain fire ratings during installation, as per installation guides (Installation Methods for ACM Panels).

Maintenance

Both materials are low-maintenance, with aluminum surfaces easy to clean and resistant to staining. ACM might require slightly more attention if its core affects long-term performance, but generally, both need minimal upkeep, as mentioned in durability assessments.

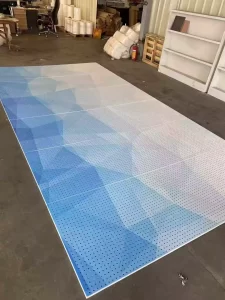

Aesthetics

Both offer extensive customization options, including various colors, finishes (e.g., matte, glossy, metallic), and textures. Their aesthetic appeal is comparable, with both suitable for modern architectural designs.

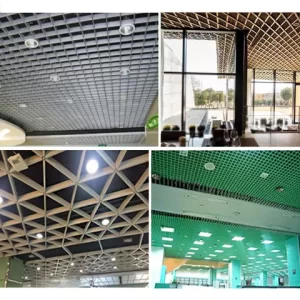

Application Scenarios

- ACP: Best for interior applications, low-rise buildings, or areas with less stringent fire safety needs, such as office lobbies or signage, due to its cost-effectiveness and lighter weight.

- ACM: Preferred for high-risk scenarios like high-rise buildings, hospitals, and schools, where fire safety is critical, as its fire-resistant properties meet regulatory demands (Aluminium Composite Panels vs Aluminium Sheeting).

Environmental Impact

- ACP: Has a higher environmental impact due to its polyethylene core, a petroleum-based product with a significant carbon footprint during production and disposal.

- ACM: Potentially more environmentally friendly, with a mineral-filled core that may have a lower environmental impact, though aluminum extraction still poses challenges. Sources highlight ACM’s recyclability as a sustainability factor (The Environmental Impact of ACM Panels).

Regulatory Compliance

- ACM: More likely to comply with stringent fire safety regulations, especially in regions with high building codes, due to its fire-resistant properties.

- ACP: May not meet higher fire safety standards, limiting its use in regulated environments, as noted in fire rating discussions.

Thermal Performance

Both provide thermal insulation, with the core material influencing performance. Polyethylene in ACP offers moderate insulation, while ACM’s mineral-filled core might vary, but specific thermal conductivity data suggests similar performance, with potential variations based on core type.

Sound Insulation

Both offer sound insulation, with the core providing a barrier. High-quality ACM might perform better due to denser cores, reducing noise transfer, as mentioned in product benefits (Product Guides | ACM Panels).

Flexibility in Design

Both are highly flexible, allowing bending, cutting, and shaping for various architectural designs. Their versatility is similar, with both suitable for complex shapes. Check out the comparison table below, and you will know how to choose the Right Aluminum Composite Panel for Your Project.

| Aspect | ACP | ACM |

| Core Material | Polyethylene (PE) | Fire-resistant (e.g., mineral-filled) |

| Fire Resistance | Lower (flammable) | Higher (fire-resistant) |

| Weight | Lighter | Slightly heavier |

| Cost | Less expensive | More expensive |

| Installation | Similar to ACM | Similar to ACP |

| Maintenance | Low | Low |

| Aesthetics | High, customizable | High, customizable |

| Application Scenarios | Interiors, low-rise | High-rises, high-risk areas |

| Environmental Impact | Higher due to PE | Potentially lower |

| Regulatory Compliance | May not meet strict codes | Meets strict fire codes |

| Thermal Performance | Moderate insulation | Varies, potentially similar |

| Sound Insulation | Moderate | Potentially better |

| Flexibility in Design | High | High |

Alumideas is a professional exterior wall panel manufacturer. If you have more questions about ACM and ACP, please contact our professional team to answer your questions. You are also welcome to consult us on project procurement issues.

Looking For a ACM Supplier For Your Projects?

Alumideas is a aluminum facade manufacturer in China. We provide a one-stop solution for your interior and exterior decorative cladding projects. Ask for a quote now!

We will contact you within 1 working day, please pay attention to the email with the suffix “@alumideas.com”.